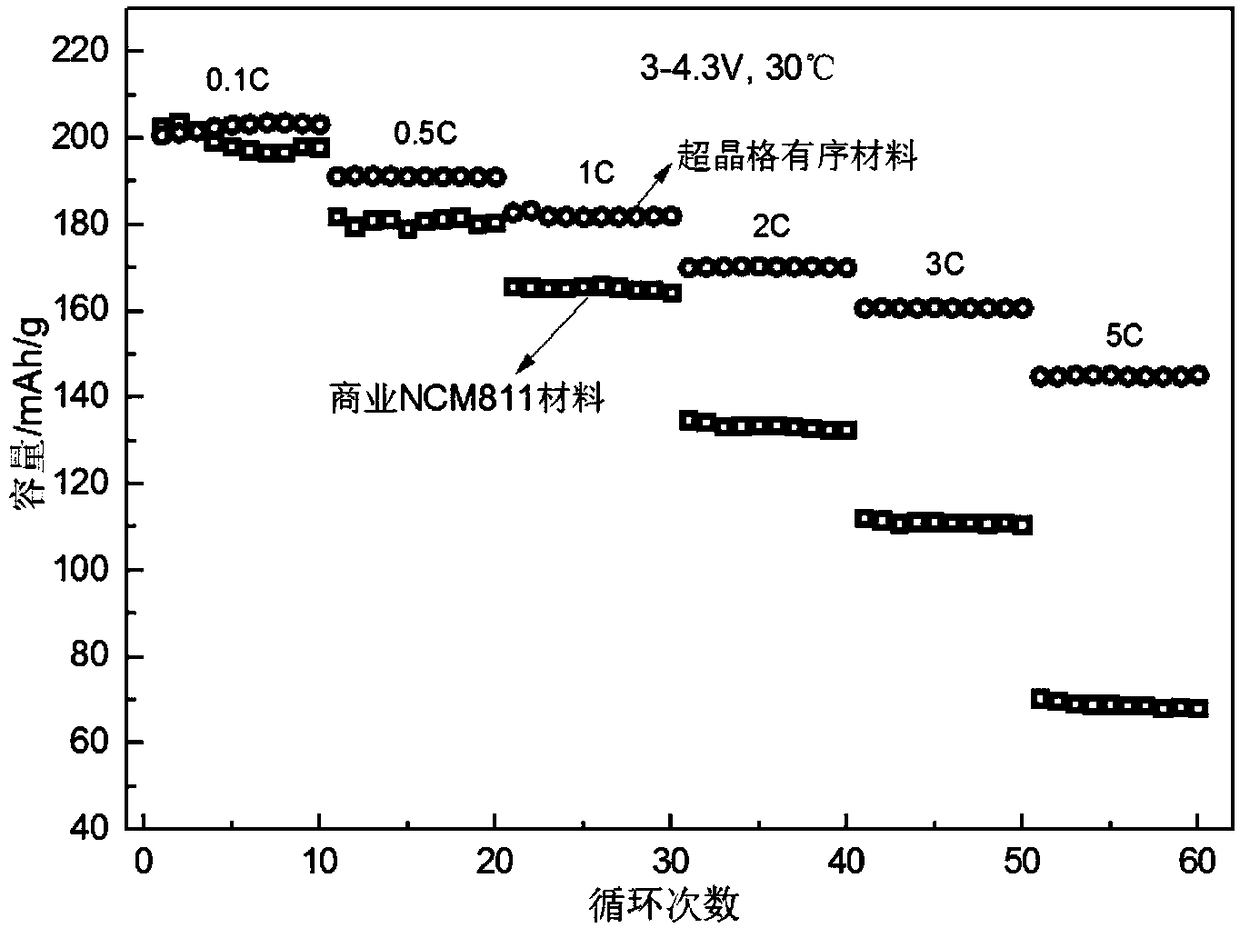

Lithium-ion battery cathode material with super-lattice ordered structure and synthesizing method thereof

A lithium-ion battery and ordered structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of material particle fragmentation, low lithium ion conductivity, poor structural stability, etc., and achieve high magnification The effect of high performance, simple operation, and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

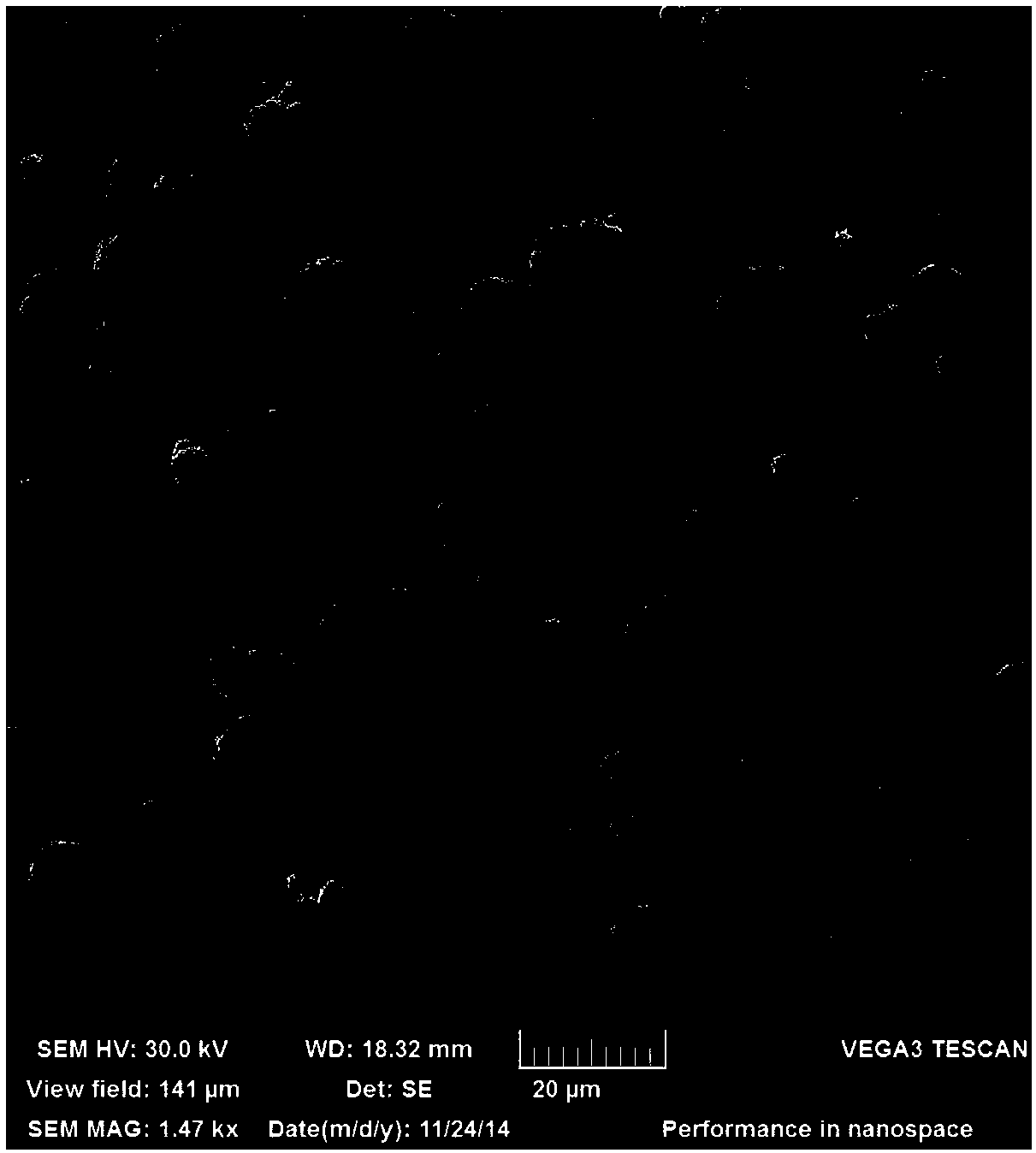

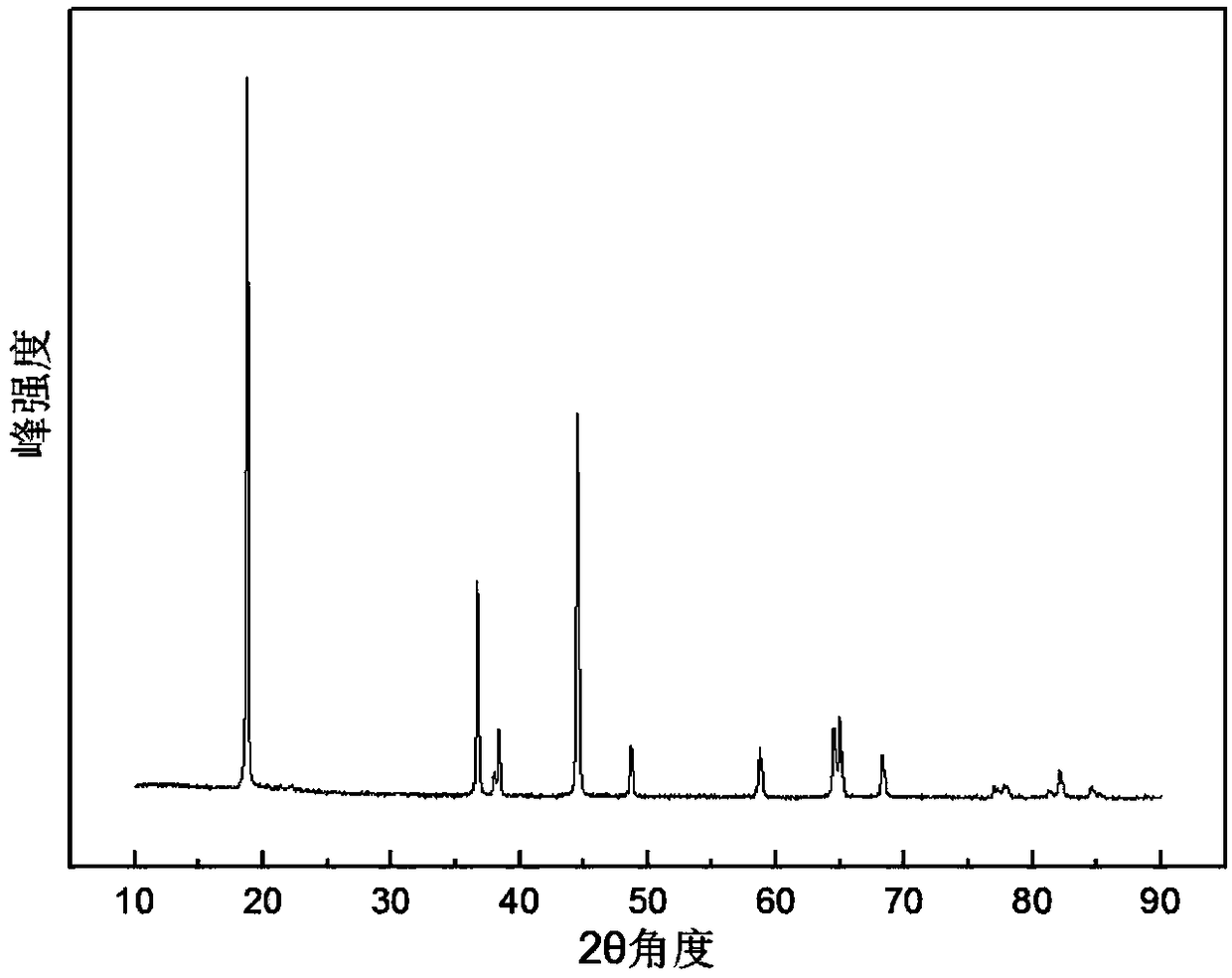

[0054] A method for synthesizing a lithium-ion layered battery cathode material with a superlattice ordered structure, the specific steps of the method are as follows:

[0055] First, the molar ratio of preparation is Ni:Co=4:1 and the nickel sulfate and cobalt sulfate mixed metal salt solution that total concentration is 2.0mol / L, and the preparation molar ratio is Ni:Mn=4:1 and total concentration is 2.0mol / L L of nickel sulfate and manganese sulfate mixed metal salt solution, 4.0mol / L complexing agent ammonia solution, 2.0mol / L precipitant sodium hydroxide solution.

[0056] Get 4.0mol / L complexing agent ammonia solution and dilute it into 0.5mol / L ammonia solution and add it to the reaction kettle as the reaction bottom liquid. inert N 2 Under the protection of the atmosphere, heat the reaction bottom solution to 50°C, and then mix the two mixed metal salt solutions, ammonia solution, and sodium hydroxide solution at a rate of 1.0mL / min:1.0mL / min:1.0mL / min:5mL / min Gradua...

Embodiment 2

[0066] A method for synthesizing a lithium-ion layered battery cathode material with a superlattice ordered structure, the specific steps of the method are as follows:

[0067] First, the molar ratio of preparation is Ni:Co=3:2 and the nickel sulfate and cobalt sulfate mixed metal salt solution that the total concentration is 2.0mol / L, and the preparation molar ratio is Ni:Mn=3:2 and the total concentration is 2.0mol / L L of nickel sulfate and manganese sulfate mixed metal salt solution, 4.0mol / L complexing agent ammonia solution, 2.0mol / L precipitant sodium hydroxide solution.

[0068] Get 4.0mol / L complexing agent ammonia solution and dilute it into 0.4mol / L ammonia solution and add it to the reaction kettle as the reaction bottom liquid. inert N 2 Under the protection of the atmosphere, heat the reaction bottom solution to 60°C, and then mix the two mixed metal salt solutions, ammonia solution, and sodium hydroxide solution at a rate of 1.0mL / min:1.0mL / min:1.0mL / min:5mL / min...

Embodiment 3

[0072] A method for synthesizing a lithium-ion layered battery cathode material with a superlattice ordered structure, the specific steps of the method are as follows:

[0073] First, the molar ratio of preparation is Ni:Co=3:2 and the nickel sulfate and cobalt sulfate mixed metal salt solution that total concentration is 2.0mol / L, and preparation molar ratio is Ni:Mn=2:2 and total concentration is 2.0mol / L L of nickel sulfate and manganese sulfate mixed metal salt solution, 2.0mol / L complexing agent ammonia solution, 2.0mol / L precipitant sodium hydroxide solution.

[0074] Get 2.0mol / L complexing agent ammonia solution and dilute it into 0.5mol / L ammonia solution and add it to the reaction kettle as the reaction bottom liquid. inert N 2 Under the protection of the atmosphere, heat the reaction bottom solution to 80°C, and then mix the two mixed metal salt solutions, ammonia solution, and sodium hydroxide solution at a rate of 1.0mL / min:1.0mL / min:1.0mL / min:5mL / min Gradually ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com