Hydrophilic polyvinylidene fluoride resin

A polyvinylidene fluoride resin, hydrophilic technology, applied in water/sewage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc. problems, to achieve the effect of good water treatment capacity, low intrinsic viscosity, and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

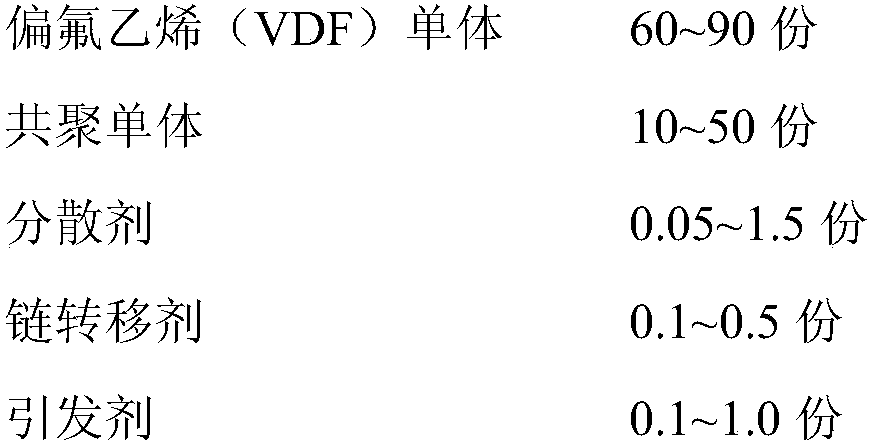

[0023] A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0024]

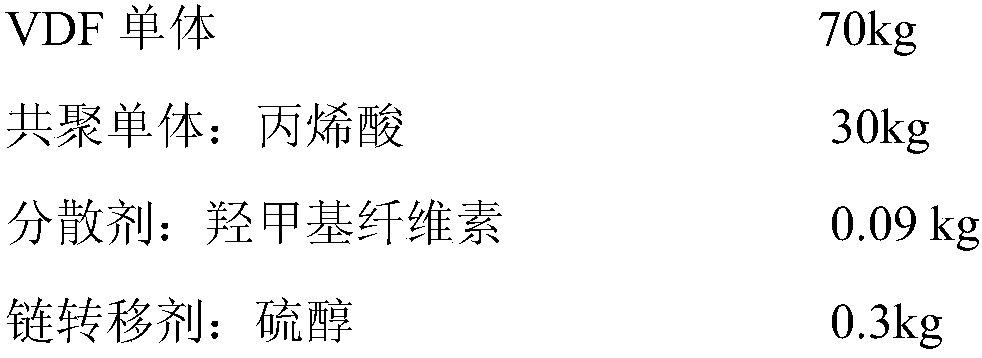

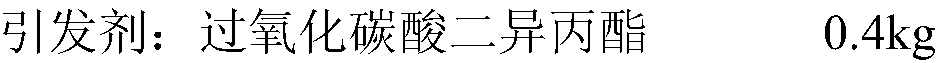

[0025]

[0026] The preparation method is as follows:

[0027] (1) Suspension polymerization

[0028] After adding 240kg of deionized water to the polymerization kettle, replace it with high-purity nitrogen gas. After the replacement is qualified, add 70kg of VDF monomer, 30kg of acrylic acid, 0.09kg of hydroxymethyl cellulose, 0.3kg of mercaptan, 0.4kg of diisopropyl peroxycarbonate and 10kg of deionized water was reacted at a stirring speed of 55rpm, the reaction temperature was 35°C, the reaction time was 12h, and the reaction pressure was 2.7Mpa to obtain a suspension polymerization product;

[0029] (2) Post-processing of suspension polymerization products

[0030] Wash the suspension polymerization product obtained in step (1) three times with deionized water (washing speed: 30rpm), then wash three times with deionized water at 60°C, then centrifuge and ...

Embodiment 2

[0032] A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0033]

[0034] The preparation method is the same as in Example 1, and the analytical data of the product are shown in Table 1.

Embodiment 3

[0036] A kind of hydrophilic polyvinylidene fluoride resin, its raw material formula is as follows:

[0037]

[0038] The preparation method is the same as in Example 1, and the analytical data of the product are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com