High-speed water-based gravure paper ink as well as preparation method and application thereof

A water-based, paper-based technology, applied in inks, applications, household appliances, etc., can solve the problems of low permeability, achieve low odor, save ink usage costs, and clear printing patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

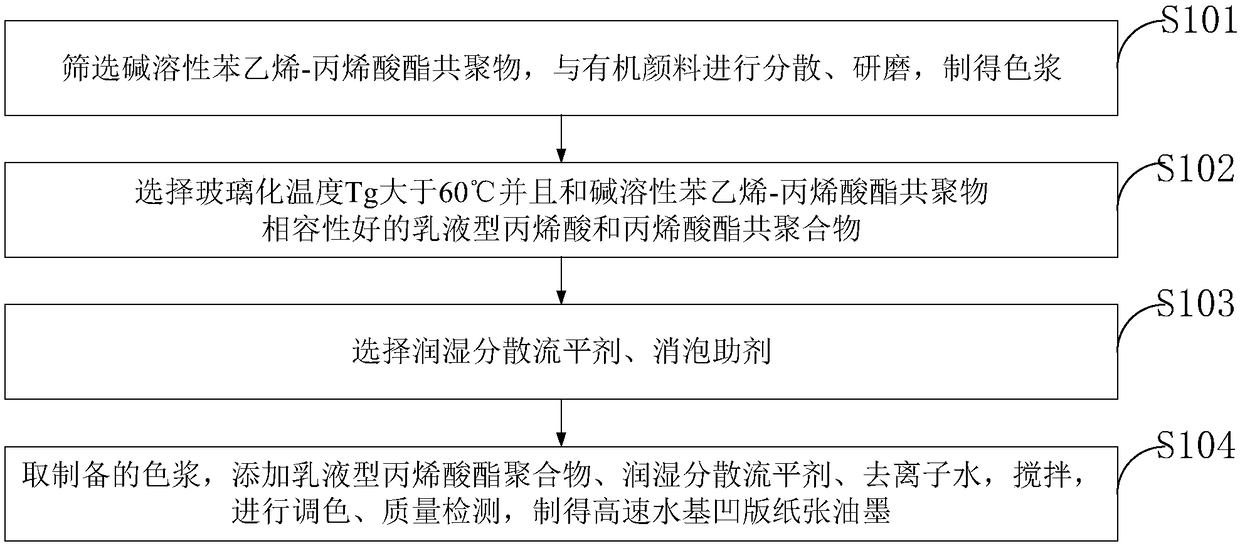

[0040] The preparation method of high-speed water-based gravure paper ink of the present invention comprises:

[0041] Firstly, the alkali-soluble styrene-acrylate copolymer is screened, dispersed and ground with high-quality organic pigments through a special process, and a color paste with high color concentration and stable fluid is obtained;

[0042] Secondly, choose a glass transition temperature (Tg) greater than 60 ° C, and good compatibility with alkali-soluble styrene-acrylate copolymers and emulsion-type acrylic acid and acrylate copolymers to improve the drying speed of the ink and the physical properties of the ink film. Mechanical properties such as hardness, mechanical strength, wear resistance and heat resistance.

[0043] Again, select additives such as production, storage stable wetting and dispersion, various additives with excellent leveling and defoaming effects to improve the printability of inks such as pigment wettability, dispersibility, stability, ink ...

Embodiment 1

[0067] The preparation method of the high-speed water-based gravure paper ink provided by the embodiment of the present invention comprises:

[0068] The first step, take 30g styrene-acrylate copolymer, 36g organic pigment, 0.6g defoamer, 33.4g clean water, after soaking for 12 hours, stir and disperse at high speed (1500 rpm) for 30 minutes, grind 4 times, namely Produce high-concentration color paste;

[0069] In the second step, take 40g of color paste, 38g of emulsion type acrylate resin, 3g of wetting and dispersing leveling aid, 19g of clean water, stir and disperse at a medium speed (600-800 rpm) for 20-30 minutes, and then the high-speed water Based gravure paper ink.

Embodiment 2

[0071] The preparation method of the high-speed water-based gravure paper ink provided by the embodiment of the present invention comprises:

[0072] The first step, take 32g styrene-acrylic ester copolymer, 34g organic pigment, 0.5g defoamer, 33.5g clean water, after soaking for 12 hours, stir and disperse at high speed (1500 rpm) for 30 minutes, grind 4 times, namely Produce high-concentration color paste;

[0073] In the second step, take 42g of color paste, 35g of emulsion type acrylate resin, 3.7g of wetting and dispersing leveling aid, 19.3g of clean water, and stir and disperse at a medium speed (600-800 rpm) for 20-30 minutes to obtain High speed water based gravure paper ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com