Weaving machine with synchronous online cold-heat transfer printing and dyeing and pattern weaving functions and use method thereof

A transfer printing and dyeing and loom technology, applied in the textile industry, can solve the problems of excessive air flying, slow processing speed, high labor intensity, etc., achieve the effect of simple and convenient operation of loom equipment, realize machine network control, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

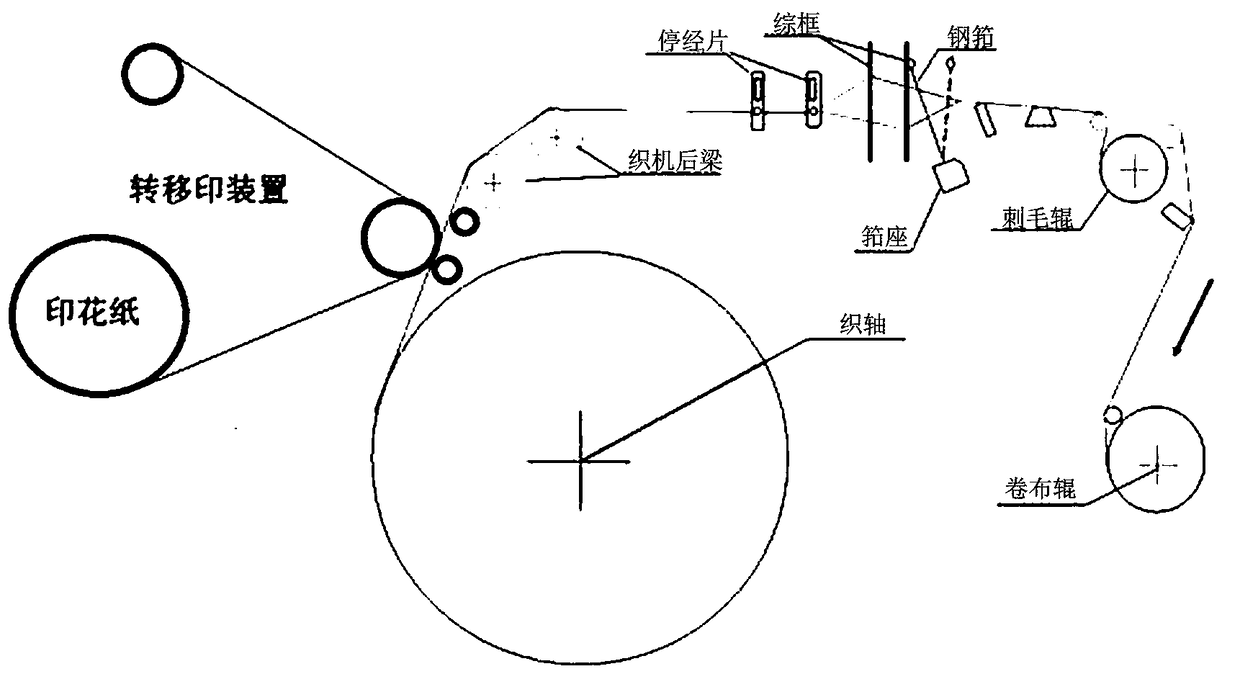

[0057] A loom with the function of on-line cold and heat transfer printing and dyeing synchronously realizing pattern weaving in this embodiment includes a transfer printing machine, a weaving shaft, a loom, and a fabric roll, and the loom is provided with a menaceer, a heald frame, and a reed in sequence. , Grizzling roller, the corresponding sley is provided under the steel reed, and the cloth rolling roller is located at the rear of the depilating roller. The transfer printing machine is located at the let-off of the textile machine: between the weaving beam and the backrest of the loom.

[0058] A kind of application method of the loom with online cold and heat transfer printing and dyeing of this embodiment to realize the function of pattern weaving synchronously is: denim loom uses white yarn warp beam through plasma, ultrasonic wave without desizing size (polyurethane, polyacrylate , cationic agent compound) sizing pretreatment to make a white yarn pulp shaft, after dra...

Embodiment 2

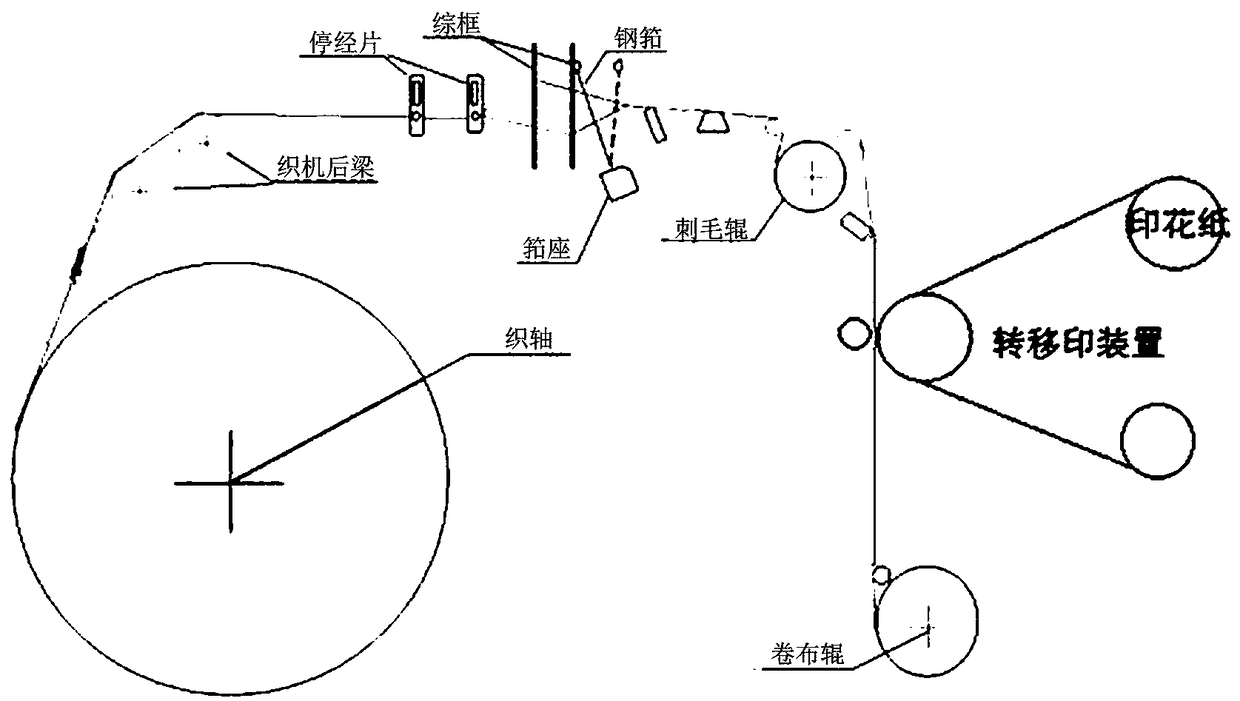

[0060] A loom with the function of on-line cold and hot transfer printing and dyeing to realize pattern weaving synchronously, including a transfer printing machine, a weaving shaft, a loom, and a cloth roll. , a corresponding sley is provided under the reed, and the cloth winding roller is located behind the deburring roller. The transfer printing machine is located between the deburring roller and the cloth rolling roller.

[0061] An application method of a loom with online cold and heat transfer printing and dyeing to realize the pattern weaving function synchronously in this embodiment is: the warp beam of the white yarn used for the denim loom is passed through plasma, ultrasonic wave without desizing size (polyacrylate, cationic agent compound) sizing pretreatment to make a white yarn pulp shaft, after threading and reeding, the pulp shaft is put on the machine (printing and weaving integrated arrow shaft loom), and the transfer printing paper is based on the design and...

Embodiment 3

[0063] The structure of a loom with the function of synchronously realizing pattern weaving in online cold and heat transfer printing and dyeing in this embodiment is the same as that in Embodiment 1.

[0064] An application method of a loom with the function of on-line cold and heat transfer printing and dyeing synchronously realizing pattern weaving in this embodiment is: the warp beam of the white yarn used for the denim loom is passed through the plasma, ultrasonic wave without desizing size (polyurethane, cationic agent composite material) sizing pretreatment to make a white yarn pulp shaft, after passing through the warp and combing the warp knitting machine, the pulp shaft is put on the machine (printing and weaving integrated warp knitting machine), and the transfer printing paper is based on the design and color of the jeans and the trousers structure required by the customer. And other technical requirements, the pattern will be printed directly by the 1PASS digital p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com