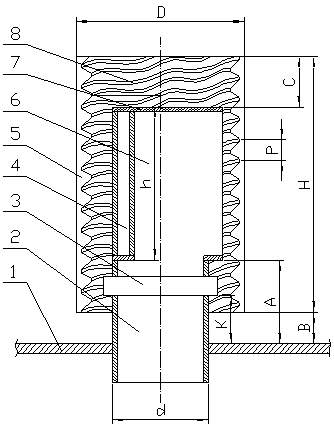

High-efficiency rotary demister

A demister and rotating technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of difficult processing, complex technical structure, high processing and manufacturing costs, and reduce mist entrainment. Realize Gas-liquid separation, not easy to scale effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

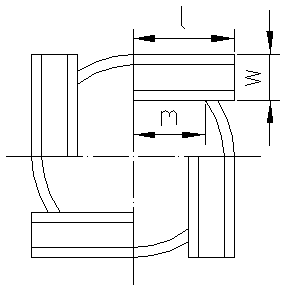

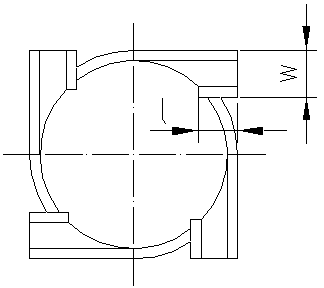

Method used

Image

Examples

Embodiment 1

[0054] A wet scrubber purifies flue gas 150000Nm 3 / h, wherein the apparent water concentration is 10-15g / Nm 3 , after demisting by the present invention, the apparent water concentration in the exhaust gas is less than 0.5g / Nm3 , Demist efficiency ≥ 95%.

Embodiment 2

[0056] A wet scrubber purifies flue gas 100000Nm 3 / h, where the apparent water concentration is 12-16g / Nm 3 , after demisting by the present invention, the apparent water concentration in the exhaust gas is less than 0.6g / Nm 3 , Demist efficiency ≥ 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com