High-pressure solution dehumidification and afterheat recovery device with adjustable pressure dew point, and high-pressure solution dehumidification and afterheat recovery method

A waste heat recovery device and solution dehumidification technology, applied in separation methods, chemical instruments and methods, compressors, etc., can solve the problems of freon leakage environment, reduced dehumidification effect, consumption, etc., and achieve the goal of reducing power consumption and improving energy utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, device

[0036] A high-pressure solution dehumidification and waste heat recovery device with adjustable pressure dew point, including a compressed air treatment system, an atmospheric pressure solution regeneration system and a chiller module;

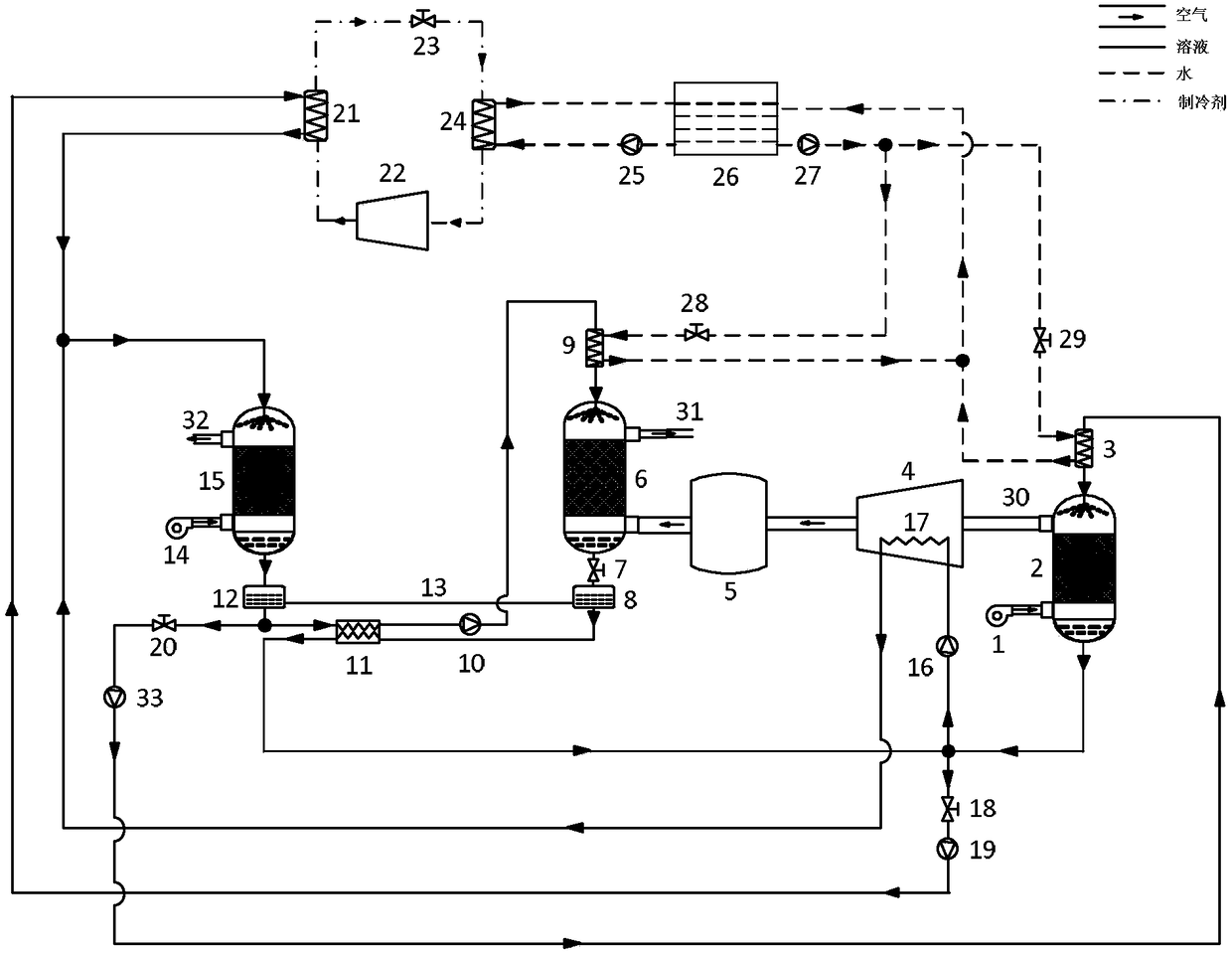

[0037] like figure 1 as shown,

[0038] The compressed air treatment system includes a normal-pressure dehumidifier 2, an air compressor 4 and a high-pressure dehumidifier 6 connected in sequence. The air outlet of the normal-pressure dehumidifier 2 is connected to the inlet of the high-pressure dehumidifier 6. In the middle passage between the dehumidifier 2 and the high-pressure dehumidifier 6, a heat exchanger 17 is arranged inside the air compressor 4;

[0039] The chiller module includes a condenser 21, a compressor 22, a throttle valve 23, an evaporator 24, and a water tank 26. The condenser 21, the throttle valve 23, the evaporator 24, and the compressor 22 are sequentially connected to form a refrigerant...

Embodiment 2

[0062] Embodiment 2, method

[0063] The method for carrying out high-pressure solution dehumidification and waste heat recovery using the device of Example 1 comprises the following steps:

[0064] 1) Compressed air treatment: wet air enters the atmospheric pressure dehumidifier 2 and contacts the concentrated solution coming in from the top for pre-dehumidification, then enters the air compressor 4, and then enters it from the bottom of the high-pressure dehumidifier 6, and flows countercurrently with it The concentrated solution from the top of the high-pressure dehumidifier 6 performs heat and mass exchange to obtain dry compressed air;

[0065] 2) Utilize condensation heat and air compressor waste heat recovery: through the refrigerant circulation path, condensation heat is generated in the condenser 21, and the dilute solution from the atmospheric pressure dehumidifier 2 and the high pressure dehumidifier 6 enters the solution side of the condenser 21, The heat of conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com