Modified high-crystallinity polypropylene composite material and preparation method thereof

A technology for composite materials and polypropylene, applied in the field of modified high-crystalline polypropylene composite materials and its preparation, can solve problems such as low rigid modulus, dimensional shrinkage, warpage, etc., and achieve reduced material density, good dimensional stability, The effect of maintaining the physical properties of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

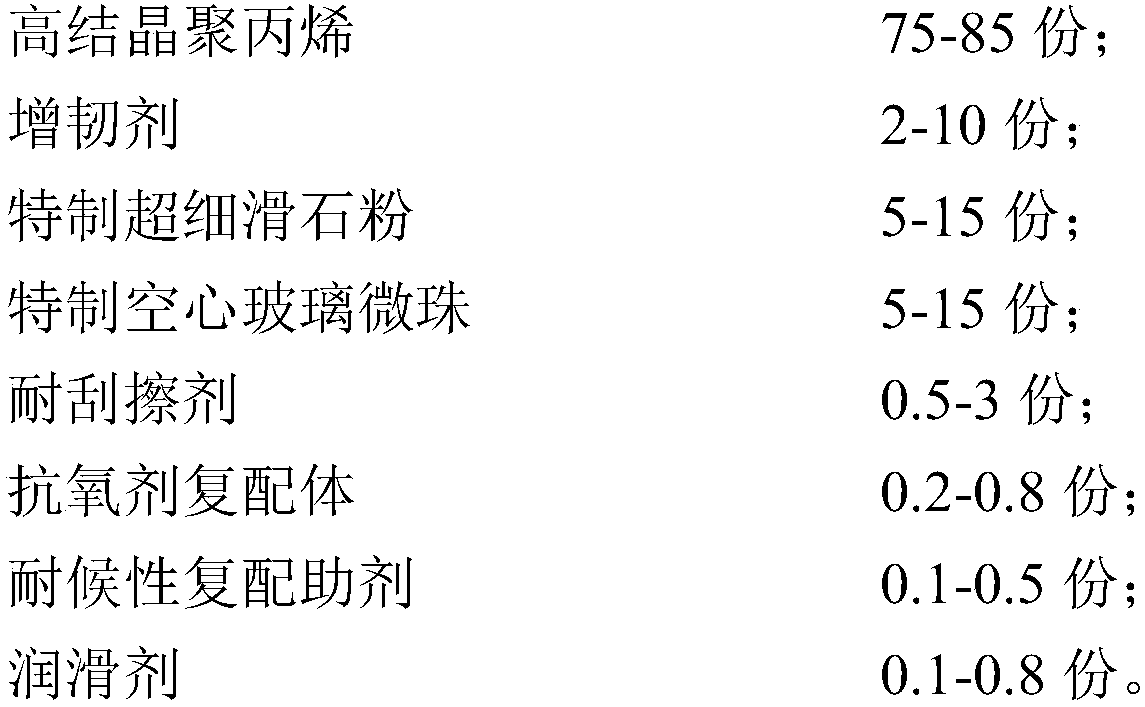

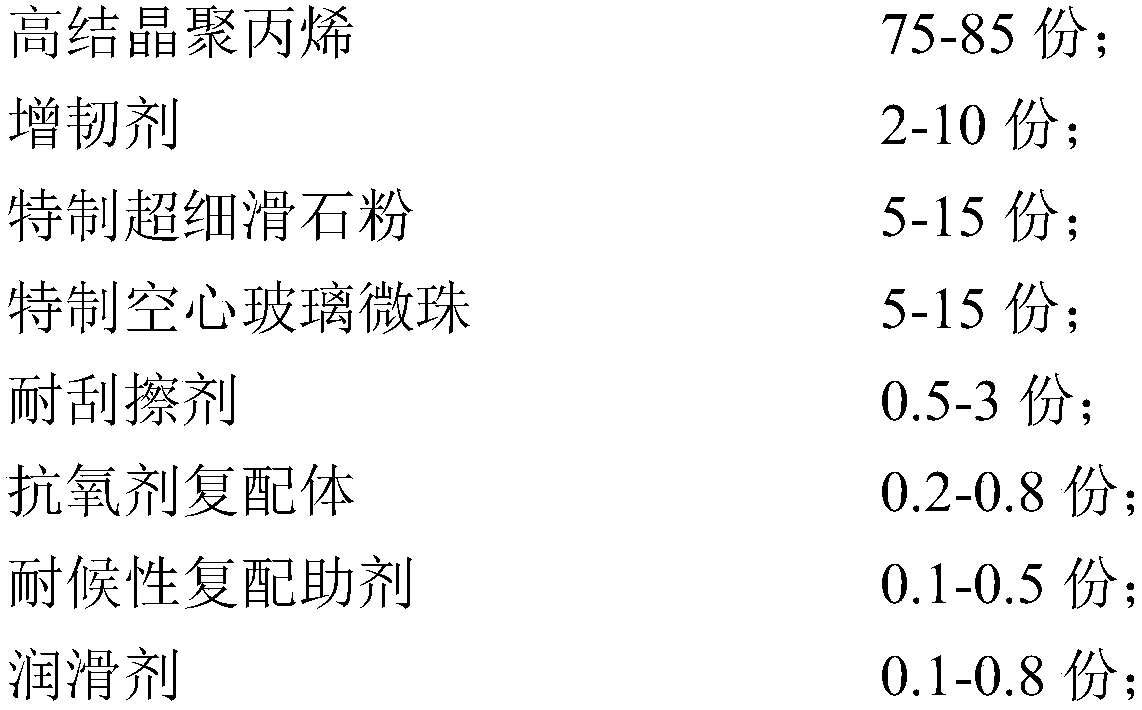

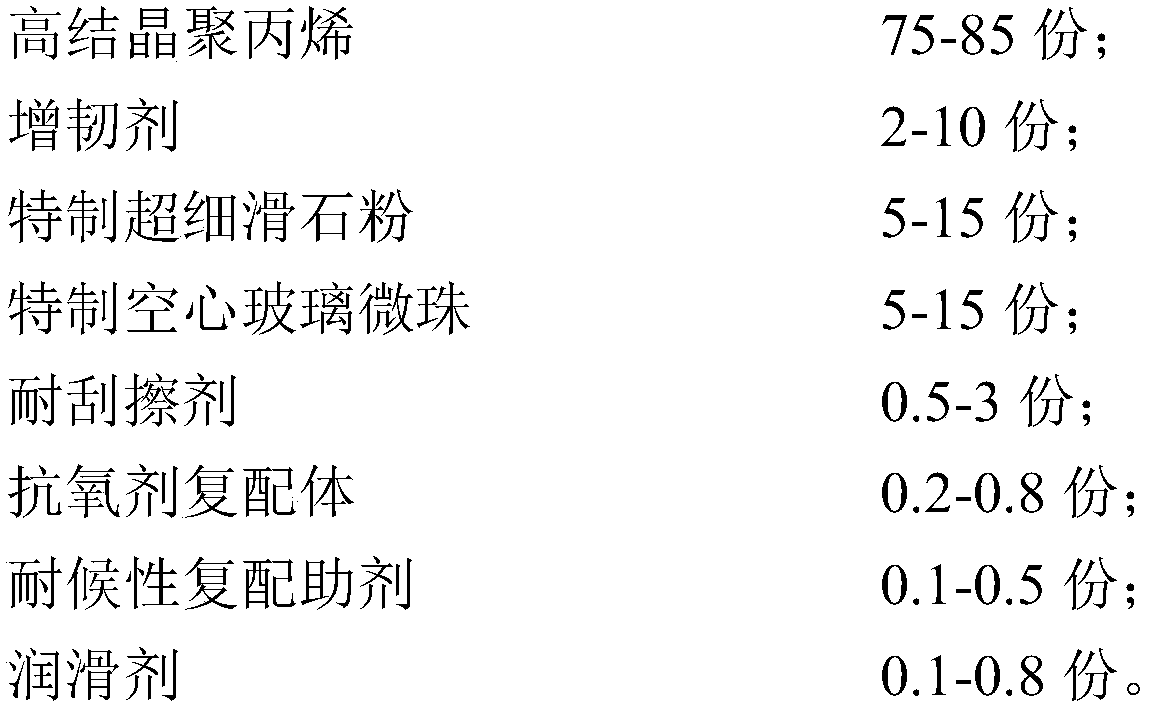

[0027] A modified high crystalline polypropylene composite material, comprising the following components, by weight:

[0028]

[0029] Prepare embodiment 1~4 and comparative example 1~2 by following preparation method

[0030] The method includes the following steps:

[0031] Step 1: Pre-dry the talcum powder with a mesh number between 2500-8000 mesh at 100-110°C to remove free water, and the time is determined according to the free water contained in the filler. (It is enough to control the water content of the filler to ≤0.3%, and the general time is 2-5 minutes). Add the dry talcum powder to the kneader, add 0.8-1.2% aluminum-titanium coupling agent UP-107 and stir, and knead at 100-120°C for 5-10 minutes before discharging.

[0032] Step 2: Pre-dry the hollow glass microspheres with a mesh number between 1250-5000 at 100-110°C to remove free water, and the time is determined according to the free water contained in the filler. (It is enough to control the water conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com