Preparation method for nanofiber membrane used for detecting ethyl carbamate

A technology of urethane and nanofiber membranes, applied in fiber treatment, biochemical fiber treatment, fiber chemical characteristics, etc., can solve the problems of long detection time, high professional technical requirements for testing personnel, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

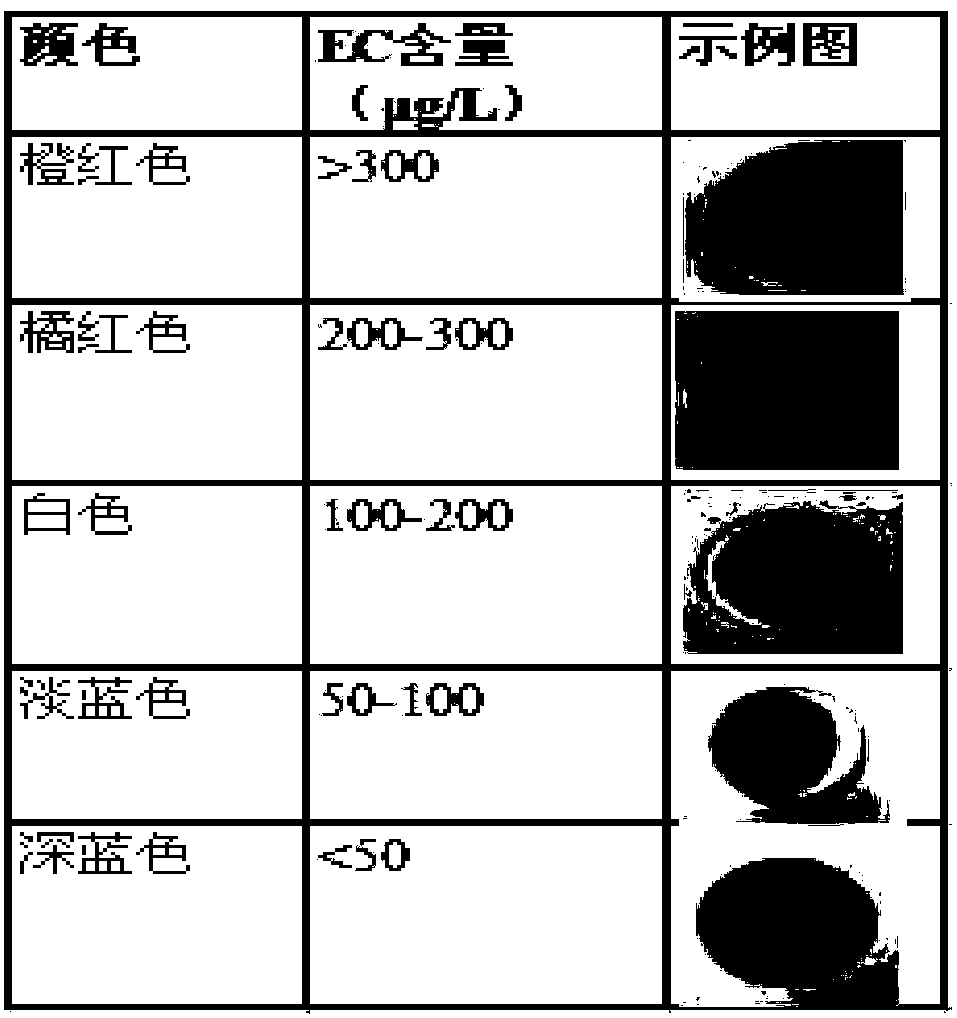

[0044] refer to figure 2 As shown in the workflow diagram, for simple, fast and accurate detection of the EC content in the sample, the application provides a method for preparing a nanofiber membrane for detecting the content of urethane, comprising the following steps:

[0045] Step 101, dissolving the spinning raw material in a solvent and mixing them uniformly to obtain a spinning stock solution, the mass concentration of the spinning stock solution is 5-20 wt / %.

[0046] During the electrospinning process, the viscosity of the spinning solution is an important factor affecting the morphology of the nanofibrous membrane. In a certain viscosity range, the viscosity of the spinning solution is high, and it is easy to form smooth and continuous nanofibers, but if the viscosity of the spinning solution is too high, the fluidity of the spinning solution will decrease, and the electric field pulling force is smaller than the viscosity of the spinning solution. , it is difficul...

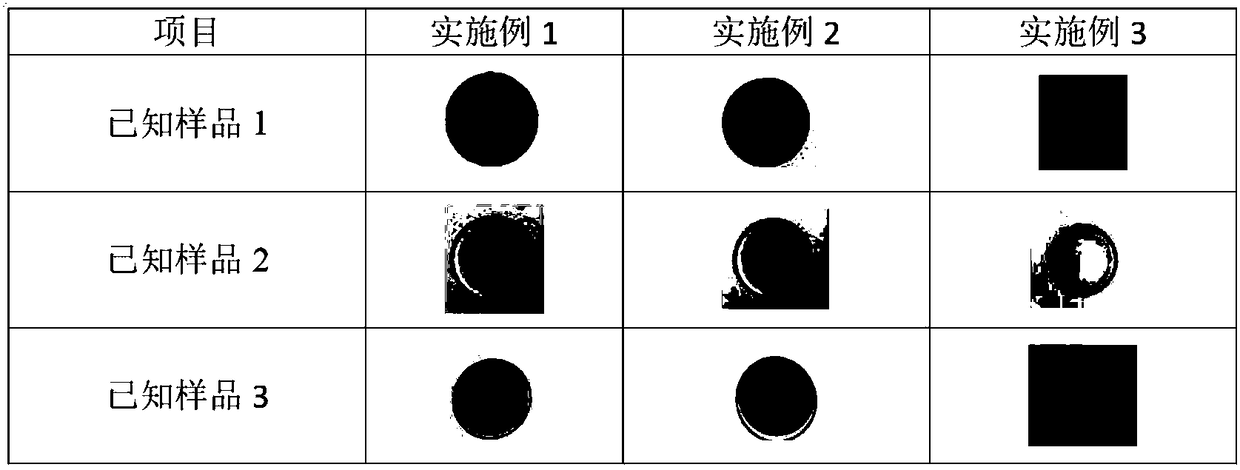

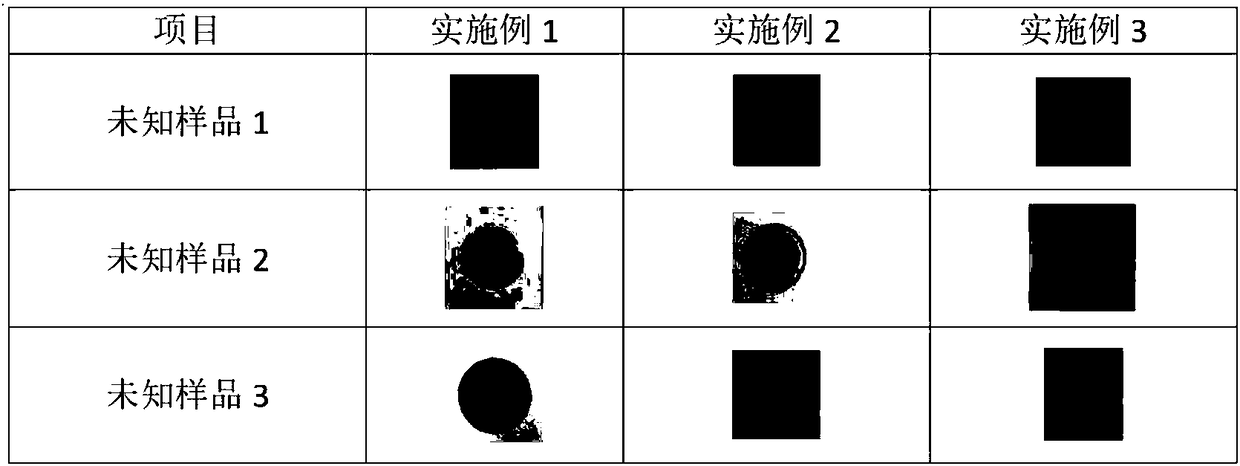

Embodiment 1

[0093] 1) Preparation of spinning solution

[0094] Select medical grade polyvinyl alcohol (polyvinyl alcohol, PVA) as the spinning raw material, weigh 20g of medical grade PVA, dissolve in 80g of deionized water, stir in a water bath at 90°C for 30min, and prepare a spinning fiber with a mass concentration of 20wt%. Silk stock solution.

[0095] Take 0.1 g of 1000 U / mg acetylcholinesterase, dissolve it in 100 mL of phosphate buffered saline (Phosphate Buffered Saline, PBS), and prepare an enzyme preparation with a concentration of 1 mg / mL. The pH of the PBS solution used in the examples of this application is 7.4.

[0096] 0.5 g of the color-developing composition and 100 mL of PBS solution were prepared into a color-developing agent with a concentration of 5 mg / mL.

[0097] Take 10 mL of the prepared spinning stock solution and 10 mL of the enzyme preparation, mix and stir at 37° C. for 20 min to obtain the spinning solution A.

[0098] Take 10 mL of the prepared spinning ...

Embodiment 2

[0102] 1) Preparation of spinning solution

[0103] Select medical-grade hydroxycellulose (Hydroxyethyl Cellulose, HEC) as spinning raw material, weigh 5g of medical-grade HEC, dissolve in 95g of deionized water, stir in a water bath at 90°C for 30min, and prepare a spinning fiber with a mass concentration of 5wt%. Silk stock solution.

[0104] Take 0.02 g of 1000 U / mg acetylcholinesterase, dissolve it in 100 mL PBS solution, and prepare an enzyme preparation with a concentration of 0.2 mg / mL. The pH of the PBS solution used in the examples of this application is 7.4.

[0105] 0.02 g of the color-developing composition and 100 mL of PBS solution were prepared to form a color-developing agent with a concentration of 0.2 mg / mL.

[0106] Take 10 mL of the prepared spinning stock solution and 10 mL of the enzyme preparation, mix and stir at 37° C. for 20 min to obtain the spinning solution A.

[0107] Take 10 mL of the prepared spinning stock solution and 5 mL of the color devel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com