Wood drying shed and building and using methods thereof

A wood drying and drying technology, used in wood drying, drying solid materials, drying chambers/containers, etc., can solve the problems of inability to effectively control the moisture content of wood, uncontrollable drying time, and difficulty in balancing investment and return. Rate controllable, quick build, short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

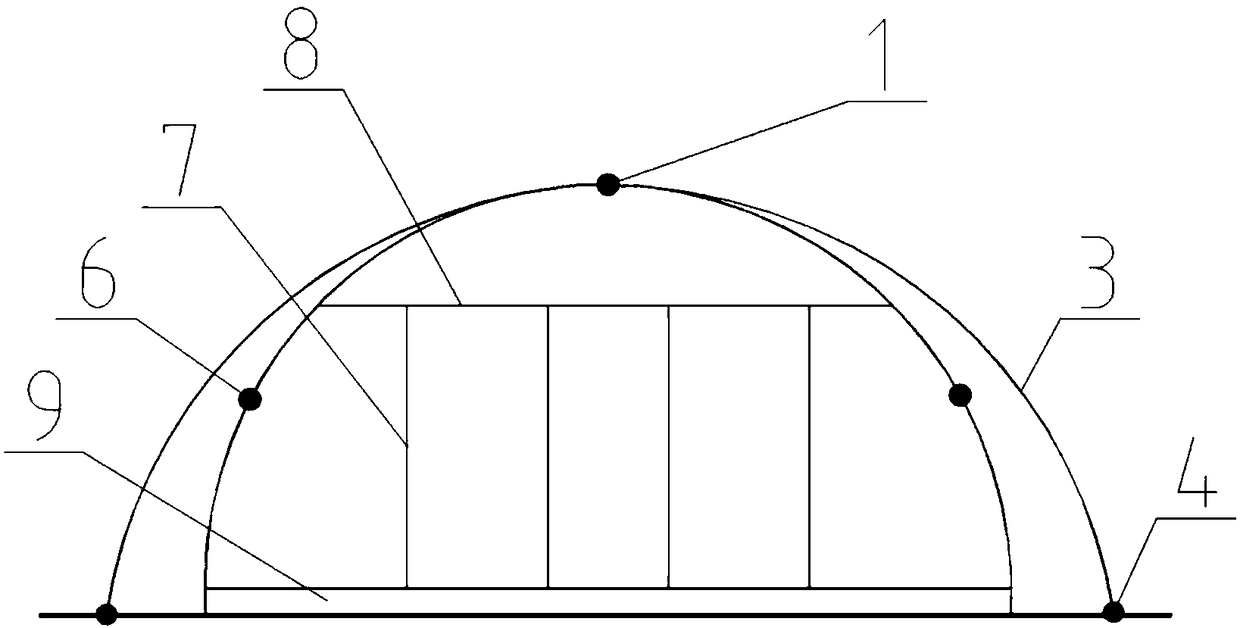

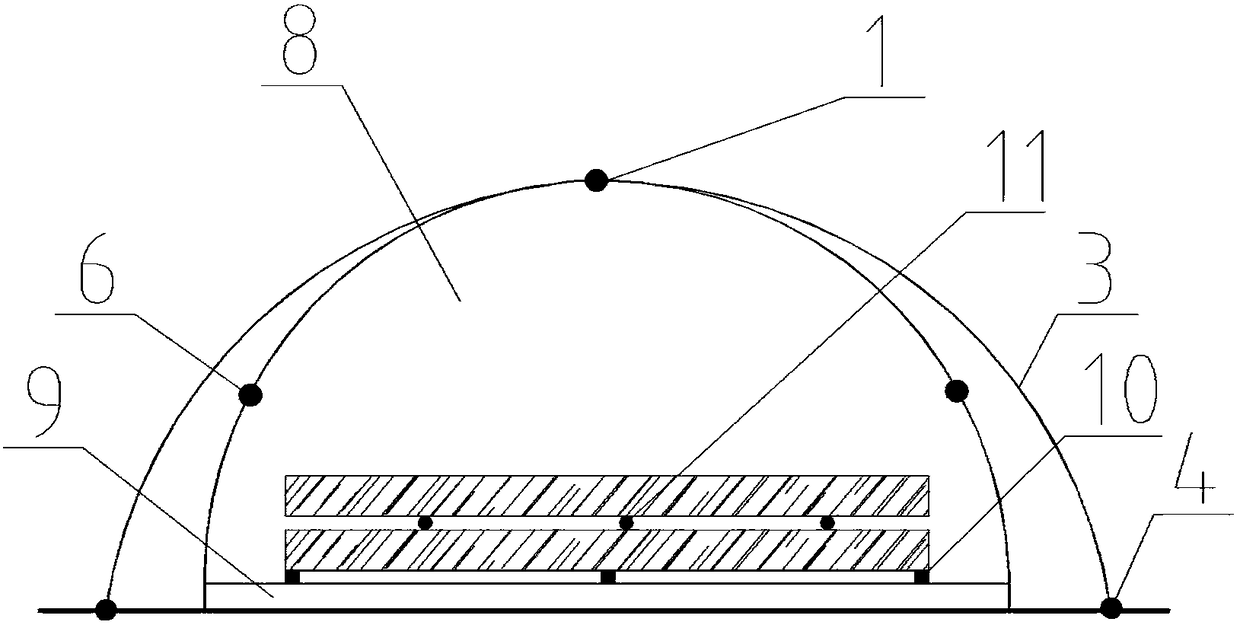

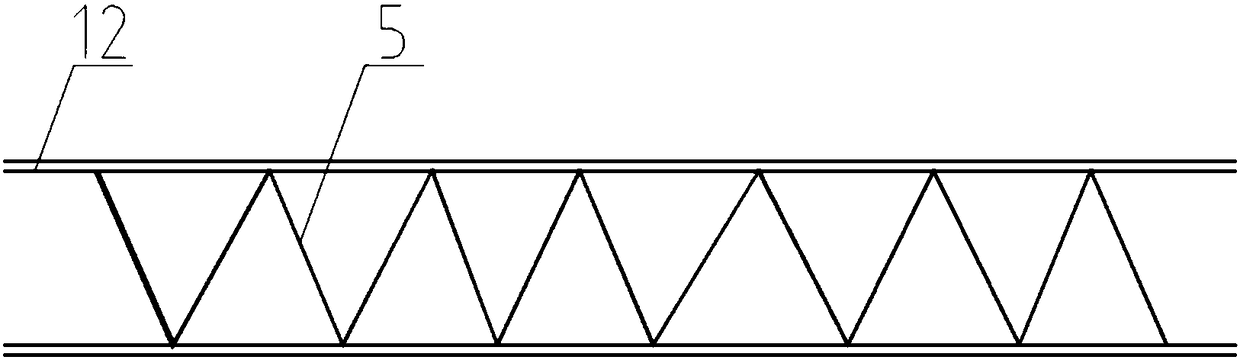

[0033] Such as figure 1 , figure 2 and image 3 As shown, a wood drying shed includes an arch 1, a film and a film door; a plurality of arches 1 are arranged regularly, and a film is fixed on the outside of the arch 1; the film door is arranged on both ends of the end; Temperature and humidity recorder, exhaust fan and heater 2; the exhaust fans are installed on the longitudinal sides of the drying shed, and two exhaust fans are installed on each side, with a distance of 3 to 6m, and the height of the exhaust fans from the ground is 1.2 to 2.1m; the heater 2 is installed on the aisle. The spacing is 3-6m.

[0034]The invention provides a wood drying shed. The arch rod 1 generally adopts a hot-dip galvanized pipe with an outer diameter of 25-32 mm and a thickness of 1-2 mm. A plurality of arch rods 1 are arranged regularly, and the distance between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com