A kind of immunomagnetic beads and its preparation method and application

An immunomagnetic bead, cross-linking reaction technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of harsh reaction conditions, complex modification process, harsh operating conditions, etc., to improve stability and increase antibody loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] an immunomagnetic bead

[0050] Step 1: Preparation of Fe 3 o4 nano magnetic core

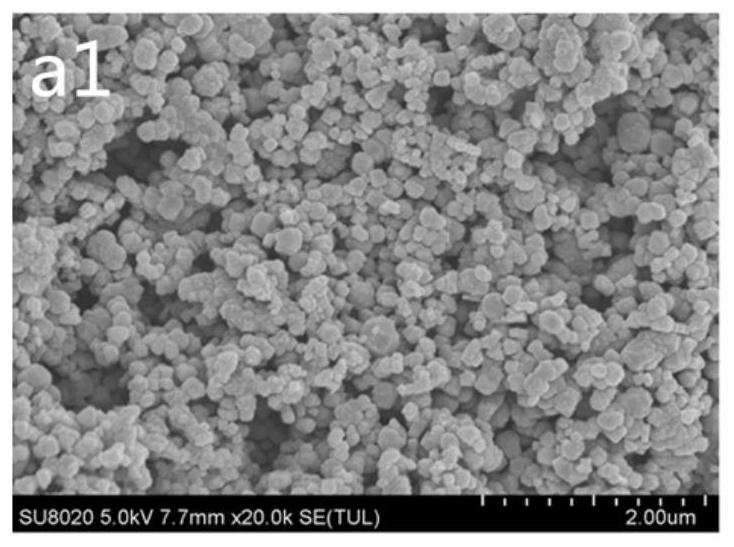

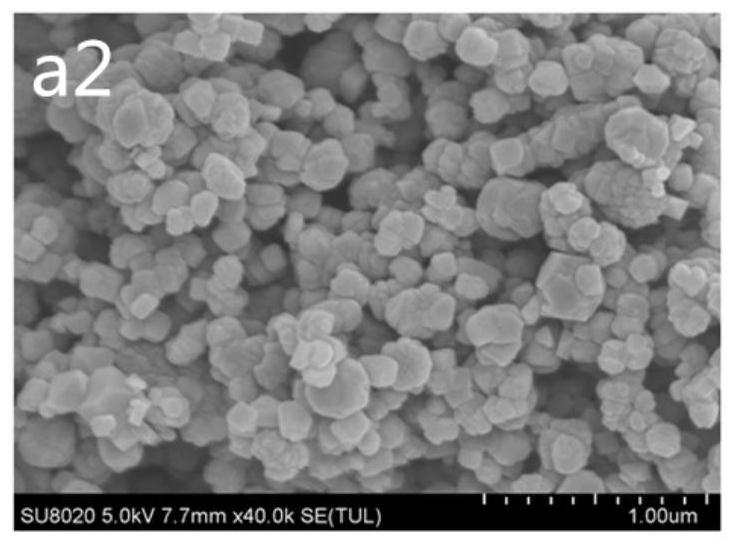

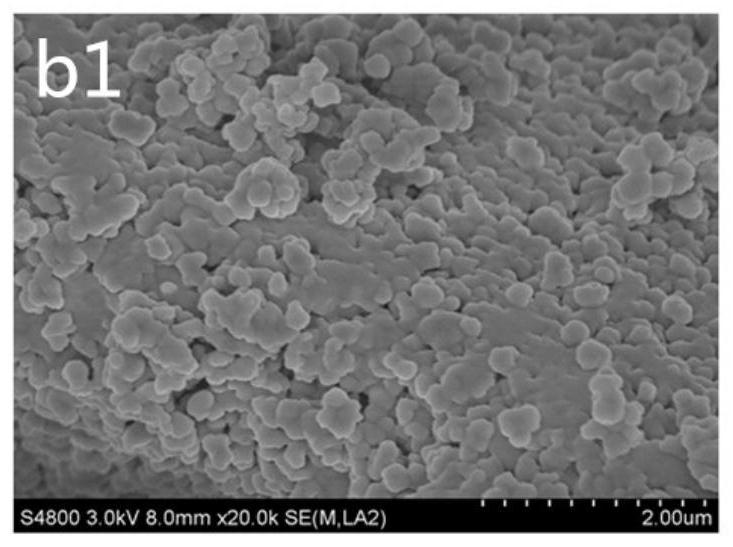

[0051] Weigh 20.0g of ferrous sulfate heptahydrate and dissolve it in 140.0mL of deionized water, heat in a water bath to 90°C and react for 1h under the condition of mechanical stirring at a speed of 400r / min. At the same time, another 1.6 g of potassium nitrate and 11.2 g of potassium hydroxide were dissolved in 60.0 mL of deionized water, and the prepared solution was added dropwise (1 mL / min) into the ferrous ion solution with a constant flow pump. Continue to stir at 90°C for 2 hours after the addition to obtain a black turbid solution, which is washed several times with deionized water and dried. The black solid is ferric oxide, and its SEM image is as follows figure 1 and 2 , Fe 3 o 4 The particle size of the nano-magnetic nuclei is between 100 and 300nm, the spheres of the magnetic nuclei are unstable, and some of the magnetic nuclei are irregular. Due to the relatively act...

Embodiment 2

[0092] Its difference with embodiment 1 is that AMP&ZnCl 2 The reaction conditions for hydrogel-coated magnetic beads are different, as follows.

[0093] Weigh 0.3 g of adenosine monophosphate disodium salt and dissolve it in 20 mL of HEPES buffer (10 mM, pH 7.4), then add 200 mg of ferric oxide, and stir thoroughly. Add 150mL of paraffin wax mixture containing 6.5% Span 80 dropwise under stirring, form an emulsified system after stirring at 500r / min, continue stirring for 30min and heat to 40°C in a water bath, then add 3mL of glutaraldehyde solution (C 5 h 8 o 2 , volume fraction 25%), constant temperature cross-linking reaction 30min. Lower the temperature, add 2mL 1mg / mL ZEA monoclonal antibody dropwise (1mL / min) into the reaction system with a constant flow pump at room temperature, stir well, then add 10mL 50mM ZnCl dropwise (1mL / min) with a constant flow pump 2 Solution, cross-linking reaction at room temperature for 2h.

[0094] After the reaction, wash several ti...

Embodiment 3

[0097] Its difference with embodiment 1 is that AMP&ZnCl 2 The reaction conditions for hydrogel-coated magnetic beads are different, as follows.

[0098] Weigh 0.3g of adenosine monophosphate disodium salt and dissolve in 20mL of HEPES buffer (10mM, pH 7.4), then add 200mg of ferric oxide, and stir thoroughly. Add 150mL of paraffin wax mixture containing 6.5% Span 80 dropwise under stirring, form an emulsified system after stirring at 500r / min, continue stirring for 30min and heat to 45°C in a water bath, then add 3mL of glutaraldehyde solution (C 5 h 8 o 2 , volume fraction 25%), constant temperature cross-linking reaction 25min. Lower the temperature, add 2mL 1mg / mL ZEA monoclonal antibody dropwise (1mL / min) into the reaction system with a constant flow pump at room temperature, stir well, then add 10mL 50mM ZnCl dropwise (1mL / min) with a constant flow pump 2 Solution, cross-linking reaction at room temperature for 2h.

[0099] After the reaction, wash several times wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com