Method for preparing high magnetic sintered NdFeB by hot isostatic pressing and low temperature sintering

A technology of low-temperature sintering and hot isostatic pressing, which is applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of narrow and small magnet sizes, achieve high coercive force, large diffusion depth, and improve diffusion The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

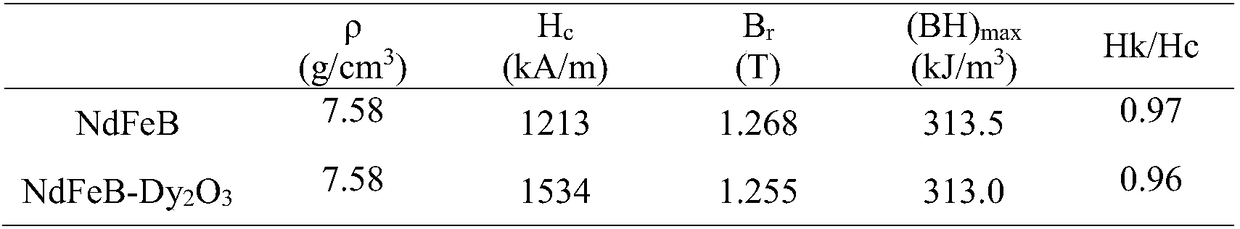

Embodiment 1

[0025] 1.5cm thick NdFeB magnet with a density of 90% is coated with Dy 2 o 3 Suspension, the coating thickness is 1.0mm;

[0026] Step 1: The NdFeB magnetic powder is oriented and formed under a magnetic field of 1.2T, and the green body is semi-densified and sintered in a vacuum sintering furnace. The sintering temperature is 950°C, kept for 1.5h, and the density is 90%;

[0027] Step 2: Put Dy 2 o 3 The powder is dispersed in anhydrous ethanol, and after mixing evenly, a suspension is obtained with a viscosity of 200mpa.s; the suspension is evenly coated on the surface of a sintered NdFeB magnet with a density of 90% in a glove box, and the coating thickness is 1.0mm, vacuum-dried in a vacuum oven at a drying temperature of 40°C for 45 minutes;

[0028] Step 3: Containing Dy 2 o 3 The coated semi-dense sintered NdFeB is placed in a glass tube, and then the glass tube is vacuum sealed with a vacuum degree of 10 -2 Above Pa;

[0029] Step 4: Put the sample of the vacu...

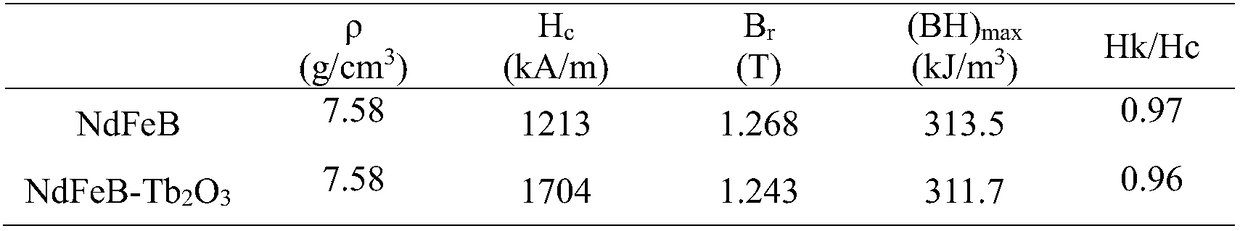

Embodiment 2

[0035] 1.5cm thick NdFeB magnet with 87% density coated with Tb 2 o 3 Suspension, the coating thickness is 0.8mm;

[0036] Step 1: The NdFeB magnetic powder is oriented and formed under a magnetic field of 1.8T, and the green body is semi-densified and sintered in a vacuum sintering furnace. The sintering temperature is 900 ° C, kept for 1 hour, and the density is 87%;

[0037] Step 2: Put Tb 2 o 3 Disperse the powder in acetone and mix it uniformly to obtain a suspension with a viscosity of 300mpa.s; in a glove box, evenly coat the suspension on the surface of a sintered NdFeB magnet with a density of 87%, and the coating thickness is 0.8 mm, vacuum-dried in a vacuum drying oven at a drying temperature of 35°C for 35 minutes;

[0038] Step 3: Containing Tb 2 o3 The coated semi-dense sintered NdFeB is placed in a glass tube, and then the glass tube is vacuum sealed with a vacuum degree of 10 -2 Above Pa;

[0039] Step 4: Put the sample of the vacuum glass sealed tube in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com