Preparation method of Mn-doped CoP nanowire modified nanosheet array layered structure supercapacitor electrode material

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of large contact resistance, small specific surface area, weak relaxation volume change ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

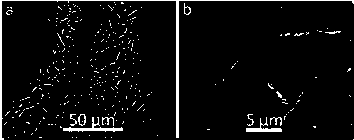

[0021] (1) Material preparation: MnSO 4 ·H 2 O (0.2 mmol), Co (NO3 ) 2 ·6H 2 O (2 mmol), urea (10 mmol), and NH 4 F (5mmol), dissolved in 40 mL deionized water, stirred evenly, a piece size is 2×3 cm 2 Nickel foam (NF) was pretreated with absolute ethanol, 5% dilute hydrochloric acid and deionized water for 10 min respectively;

[0022] (2) Hydrothermal reaction: move the solution in step (1) and the treated NF into a 50 mL polytetrafluoroethylene autoclave, seal the autoclave, place it in an oven, and react at 120 °C for 6 h;

[0023] (3) Washing and drying: After the reaction in step (2) is completed, put the polytetrafluoroethylene autoclave in the air to cool to room temperature, take out the NF evenly covered by the pink substance, wash it in ultrasonic wave for several times, and store it at 60°C Dry under vacuum for 24 h to prepare the Mn-Co hydroxide nanoarray precursor;

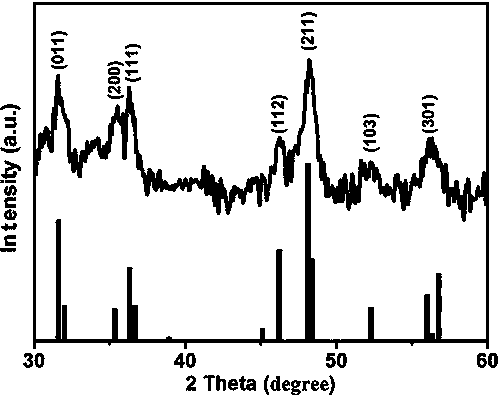

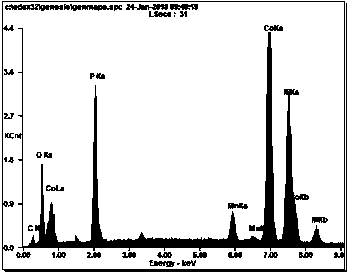

[0024] (4) Low-temperature phosphating: the Mn-Co precursor obtained in step (3) and NaH ...

example 2

[0027] (1) Material preparation: MnSO 4 ·H 2 O (0.4 mmol), Co (NO 3 ) 2 ·6H 2 O (4 mmol), urea (20 mmol), and NH 4 F (10mmol), dissolved in 80 mL deionized water, stirred evenly, one piece size is 2×3 cm 2 Nickel foam (NF) was pretreated with absolute ethanol, 5% dilute hydrochloric acid and deionized water for 10 min respectively;

[0028] (2) Hydrothermal reaction: move the solution in step (1) and the treated NF into a 100 mL polytetrafluoroethylene autoclave, seal the autoclave, place it in an oven, and react at 120 °C for 6 h;

[0029] (3) Washing and drying: After the reaction in step (2) is completed, put the polytetrafluoroethylene autoclave in the air to cool to room temperature, take out the NF evenly covered by the pink substance, wash it in ultrasonic wave for several times, and store it at 60°C Dry under vacuum for 24 h to prepare the Mn-Co hydroxide nanoarray precursor;

[0030] (4) Low-temperature phosphating: the Mn-Co precursor obtained in step (3) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com