PEN flexible substrate transparent thin film transistor and preparation method thereof

A transparent film and flexible substrate technology, applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of high cost, toxicity, cost factors and environmental protection factors of element indium, and achieve abundant resources and simplified process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

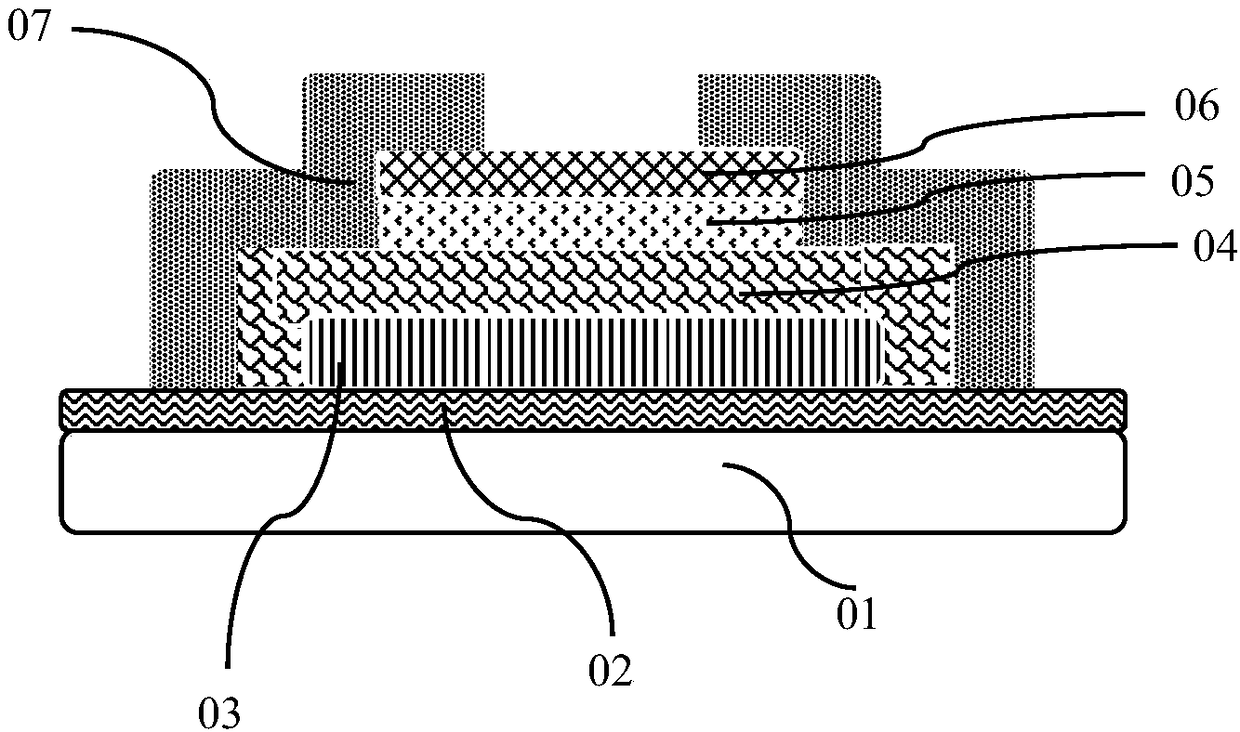

[0036] A transparent thin film transistor with a PEN flexible substrate in this embodiment, the schematic diagram of its stacked structure is as follows figure 1 shown. The glass substrate 01, flexible PEN substrate 02, AZO gate 03, Al 2 o 3 Gate insulating layer 04, IGZO semiconductor layer 05, Al 2 o 3 The semiconductor modification layer 06 and the AZO source and drain electrodes 07 are formed. The transparent thin film transistor is prepared by the following method:

[0037] (1) The glass substrate was ultrasonically cleaned with deionized water and isopropanol for about 10 minutes, and the cleaned glass substrate was placed in an oven and dried at 80-85°C.

[0038] (2) A layer of PEN flexible substrate is pasted on the cleaned and dried glass substrate with OCA glue.

[0039] (3) AZO gates of 70nm to 100nm were prepared on a PEN flexible substrate by radio frequency magnetron sputtering deposition, and the deposition process parameters were as follows: sputtering po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com