Concrete containing electrolytic manganese slag, preparation method thereof, and concrete pavement

An electrolytic manganese slag and concrete technology, applied in the field of materials, can solve the problems of increasing the cost of land requisition and site disposal of waste slag, affecting groundwater resources, and consuming large land resources. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

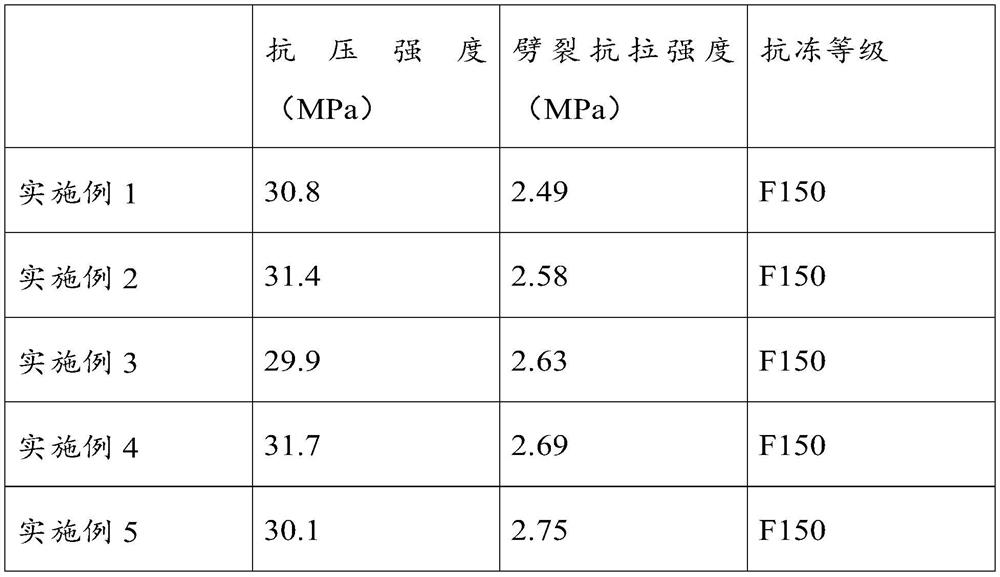

Examples

preparation example Construction

[0027] The present invention also provides a method for preparing the above-mentioned concrete containing electrolytic manganese slag, which includes:

[0028] The electrolytic manganese slag is calcined at 800-1000 DEG C, pulverized, and then graded, and the raw materials of the concrete containing the electrolytic manganese slag are prepared and mixed.

[0029] In a preferred embodiment of the present invention, the calcination is carried out for 4-5 hours, and the material is turned every 20 minutes. Under the above conditions, the electrolytic manganese slag is fully calcined, and the obtained electrolytic manganese slag calcined material has good quality, good porosity and strength.

[0030] In a preferred embodiment of the present invention, mixing includes:

[0031] First, the electrolytic manganese slag calcined material is mixed with a dispersant to obtain the first material.

[0032] In the state of stirring, mix the first material with cement, silica fume, and fly...

Embodiment 1

[0038] A concrete containing electrolytic manganese slag, which is prepared by the following method:

[0039] After preparing the raw materials, the electrolytic manganese slag calcined material is first mixed with the dispersant to obtain the first material.

[0040] In the state of stirring, mix the first material with cement, silica fume, and fly ash, continue stirring for 5 minutes, and then mix with the water reducer to obtain the second material.

[0041] Under stirring, the second material is mixed with water.

[0042] Among them, the raw materials include: 180 parts of graded electrolytic manganese slag calcined material, 14 parts of cement, 8 parts of silica fume, 13 parts of fly ash, 0.6 parts of dispersant, 1 part of water reducing agent and 11 parts of water. The dispersant is sodium dodecylbenzenesulfonate.

[0043] Among them, the graded electrolytic manganese slag calcined material is obtained by calcining electrolytic manganese slag at 900°C for 4 hours, turn...

Embodiment 2

[0046] A concrete containing electrolytic manganese slag, which is prepared by the following method:

[0047] After preparing the raw materials, the electrolytic manganese slag calcined material is first mixed with the dispersant to obtain the first material.

[0048] In the stirring state, mix the first material with cement, silica fume, and fly ash, continue stirring for 4 minutes, and then mix with the water reducing agent to obtain the second material.

[0049] Under stirring, the second material is mixed with water.

[0050] Among them, the raw materials include: 185 parts of graded electrolytic manganese slag calcined material, 17 parts of cement, 8 parts of silica fume, 14 parts of fly ash, 0.7 part of dispersant, 0.8 part of water reducing agent and 13 parts of water. The dispersant is sodium dodecylbenzenesulfonate.

[0051] Among them, the graded electrolytic manganese slag calcined material is obtained by calcining electrolytic manganese slag at 950°C for 4 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com