Method for preparing anti-reflection coating film with nano porous structure on surface of flexible base material

A flexible substrate and nano-porous technology, applied in coatings and other directions, can solve the problems of low anti-reflection efficiency and inability to realize nano-porous structure, and achieve the effects of wide application range, integrity and enhanced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Preparation of cross-linked hard particles and soft particles

[0062] Preparation of cross-linked hard particles: Weigh 2 grams of EGDMA and 18 grams of MMA sequentially in a beaker using an analytical balance, and stir for 5 minutes with a magnetic stirrer to mix the mixed monomers evenly; weigh them sequentially in another beaker 1 gram of SDS and 74.94 grams of deionized water were stirred with a magnetic stirrer for 5 minutes; the above-mentioned raw materials were added to a 250mL four-necked flask with a stirring paddle, a condenser tube and a nitrogen protection device, and the stirring speed was kept at 200-300 rpm / minute, the four-necked flask was placed in a water bath at 75°C, and the temperature of the system was guaranteed to be about 75°C. Dissolve 0.06 grams of KPS in 5mL of deionized water, add it to the four-necked flask, and react for 3 hours; the resulting emulsion was PMMA emulsion with a particle size of 58nm, that is, an emulsion of hard particl...

Embodiment 1

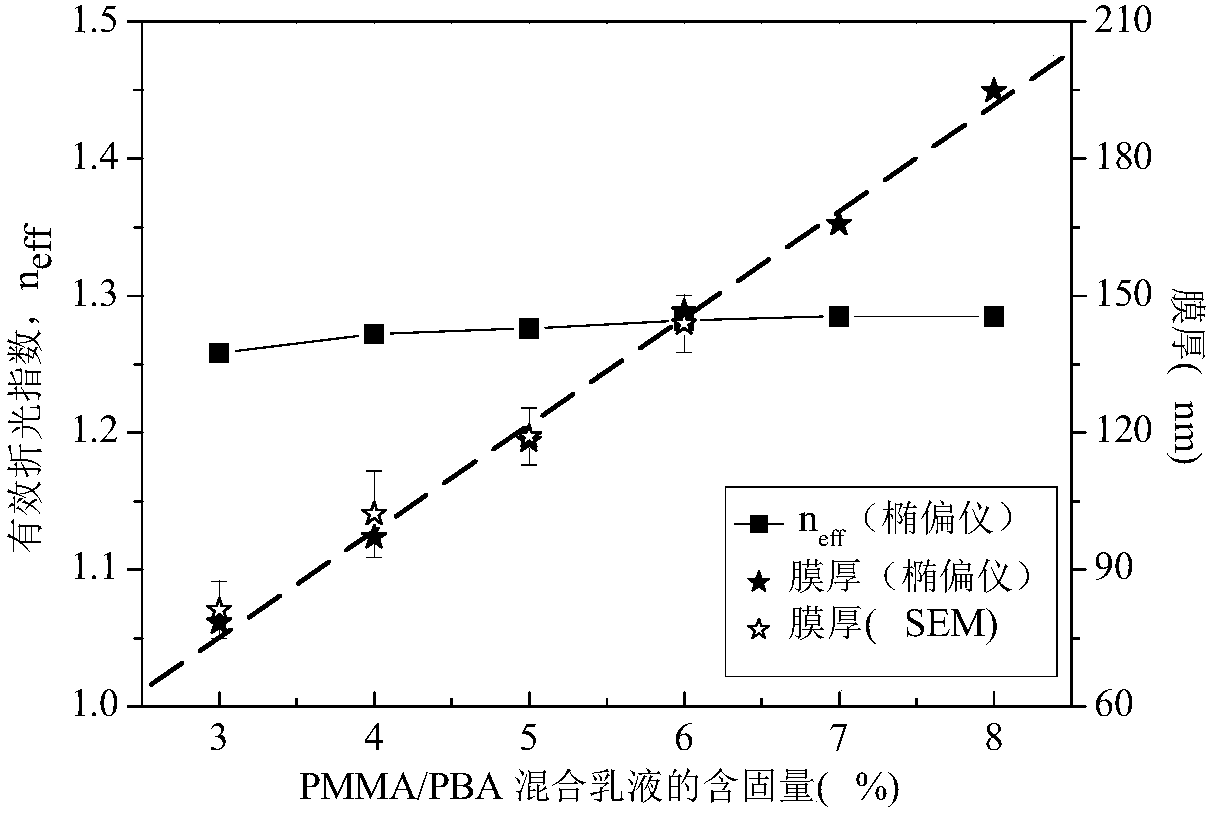

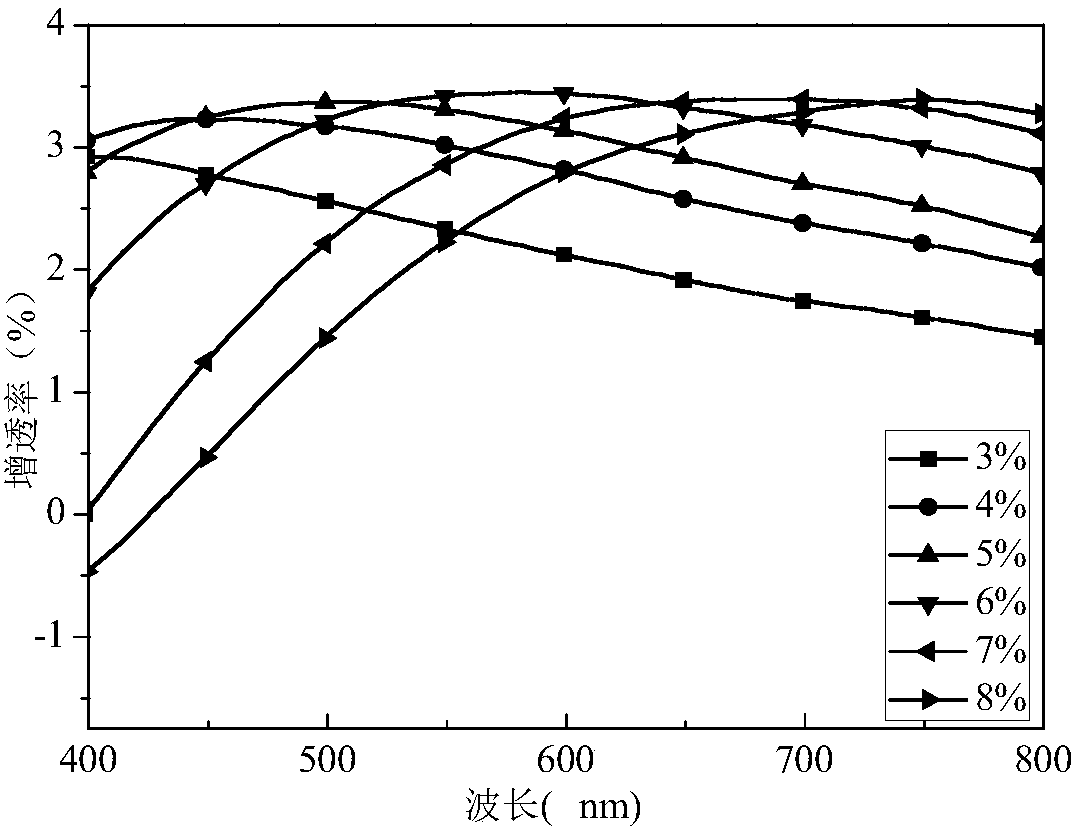

[0069] 1) Take six 25mL beakers, numbered Ⅰ, Ⅱ, Ⅲ, Ⅳ, Ⅴ and Ⅵ respectively; add 1.2 grams, 1.5 grams, 1.9 grams, 2.3 grams, 2.7 grams and 3.1 grams of hard particles into each beaker , then add 0.5 grams of soft particle PBA emulsion and 0.025 grams of SDS to each beaker to prepare a coating emulsion with a solid content of 3% to 8%;

[0070] 2) Take six 25mL beakers and mark them with No. 1, No. 2, No. 3, No. 4, No. 5 and No. 6 respectively, and add 0.15 g of NH 4 HCO 3 , and then add 5.5 g of deionized water to each of the above beakers; make the NH in each beaker 4 HCO 3 dissolve;

[0071] 3) Put the NH in the No. 1 beaker 4 HCO 3 The solution was added to the No. 1 beaker to obtain the coating solution Ⅰ-1; the NH in the No. 2 beaker 4 HCO 3 Add the solution into No. Ⅱ beaker to obtain coating solution Ⅱ-2; 4 HCO 3 The process of solution requires slow dripping, and the emulsion is constantly stirred during the dripping process, and the prepared emulsion is placed...

Embodiment 2

[0088] 1) Using the spin coating process, apply the coating solution VI-6 in Example 1 on the PET substrate, spin coating to form a film, and then place it in a blast oven at 80°C for 1 hour and take it out to obtain nano Anti-reflection coating with porous structure.

[0089] 2) The coated PET film was bent 180° multiple times, and the transmittance after bending was tested to investigate the mechanical stability of the coated film.

[0090] The planar topography figure of coating film on PET substrate in embodiment 2 is as Figure 9 Shown; PMMA / PBA mixed emulsion in embodiment 2 prepares the transmittance curve figure of coating film under different bending times as Figure 10 shown.

[0091] The scanning electron microscope on the surface of the coating film shows that the coating film coated on the PET substrate has a porous structure; the test of the optical properties of the coated glass shows that before bending, the transmittance of the coated PET substrate increases...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com