Sealed pore structure ceramic coating and preparation technology thereof

A technology of ceramic coating and closed pores, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of unstable closed pores and easy interconnection, so as to improve the heat insulation effect and reduce the thermal conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method for preparing a ceramic coating with a closed pore structure on the surface of a nickel-based alloy according to the present invention comprises the following steps:

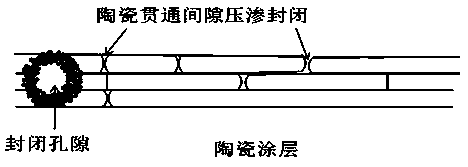

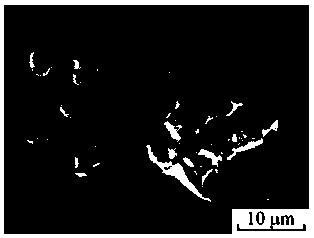

[0021] (1) ZrO with a hollow porous structure in which the volume of the hollow part in the center is 50% 2 Ceramic powder, under the condition of plasma spraying power of 30kW, the spherical shell of ceramic powder is partially melted and deposited, and a ceramic coating is prepared on the surface of nickel-based alloy, and the hollow structure of ceramic powder is retained in the ceramic coating.

[0022] (2) ZrO in the sprayed state 2 On the basis of ceramic coating (1), infiltrating Zr(OH) under the condition of 0.3MPa 4 Ceramic colloid for 20 minutes to seal cracks, through pores, etc. formed during the plasma spraying process.

[0023] (3) Heat treatment for the ceramic coating (2) after pressure infiltration, 110°C for 15 minutes to remove colloidal physical water, 280°C for ...

Embodiment 2

[0025] A method for preparing a ceramic coating with a closed pore structure on an aluminum alloy surface according to the present invention, comprising the following steps:

[0026] (1) The Al of the hollow porous structure with a volume of 80% of the hollow part in the center 2 O 3 Ceramic powder, under the condition of plasma spraying power of 25kW, the spherical shell of ceramic powder is partially melted and deposited, and a ceramic coating is prepared on the surface of the aluminum alloy material, and the hollow structure of the ceramic powder is retained in the ceramic coating.

[0027] (2) Al in spray state 2 O 3 On the basis of ceramic coating (1), infiltrating Al(OH) under the condition of 0.4MPa 3 Ceramic colloid for 20 minutes to seal cracks, through pores, etc. formed during the plasma spraying process.

[0028] (3) Heat treatment of the infiltrated ceramic coating (2), 110°C for 15 minutes to remove colloidal physical moisture, 280°C for 30 minutes to remove ...

Embodiment 3

[0031] A preparation method of the vermicular graphite cast iron surface closed pore structure ceramic coating of the present invention, comprising the following steps:

[0032] (1) ZrO with a hollow porous structure with a volume of 30% of the hollow part in the center 2 Ceramic powder, under the condition of plasma spraying power of 35kW, the spherical shell of ceramic powder is partially melted and deposited, and a ceramic coating is prepared on the surface of vermicular graphite cast iron, and the hollow structure of the ceramic powder is retained in the ceramic coating.

[0033] (2) ZrO in the sprayed state 2 On the basis of ceramic coating (1), infiltrating Zr(OH) under the condition of 0.4MPa 4 Ceramic colloid for 30 minutes to seal cracks, through pores, etc. formed during the plasma spraying process.

[0034] (3) Heat treatment for the ceramic coating (2) after pressure infiltration, remove the physical water from the colloid for 15 minutes at 110°C, remove the chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com