Microcrystalline cellulose and guar gum compound pharmaceutic adjuvant and preparation method thereof

A technology for microcrystalline cellulose and pharmaceutical excipients, which is applied in pharmaceutical formulations, medical preparations with inactive ingredients, drug delivery, etc. Can not be made into tablet form and other problems, to achieve the effect of low cost, easy acceptance, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

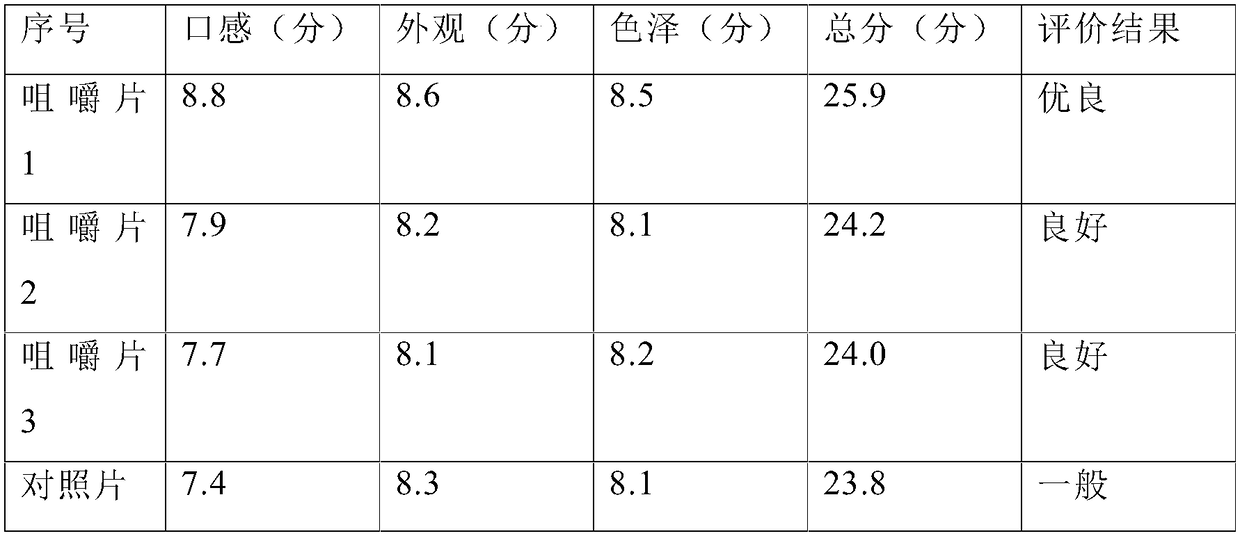

Embodiment 1

[0038] The preparation method of the pharmaceutical excipient of microcrystalline cellulose and guar gum compound chewable tablet comprises the following steps:

[0039] Add 500 kg of medical deionized water, then add 12.5 kg of pharmaceutical grade guar gum dry product, use SWFS-400 type high-speed disperser to stir, and the stirring rate is 100 rpm;

[0040] After guar gum dissolves completely, add 100 kilograms of microcrystalline cellulose (water content is 45%, polymerization degree is less than 350, and pH is 6.0); Improve stirring to 450 rpm, continue to stir for 25 minutes;

[0041] Then the resulting mixture slurry is dried with a spray drying tower, and the air inlet temperature is set to 200°C, the outlet air temperature is 130°C, the atomization speed is 50HZ, the feed flow rate is 0.5 cubic meters per hour, and the negative pressure is 300 Pa , dried, and the obtained solid powder was sieved to have a particle size d50 of 200 microns. The particle size was detecte...

Embodiment 2

[0043] The preparation method of the pharmaceutical excipient of microcrystalline cellulose and guar gum compound chewable tablet comprises the following steps:

[0044] Add 500 kg of medical deionized water, then add 12.5 kg of pharmaceutical grade guar gum dry product, use SWFS-400 type high-speed disperser to stir, and the stirring rate is 100 rpm;

[0045]After guar gum dissolves completely, add 130 kilograms of microcrystalline cellulose (water content is 45%, degree of polymerization is less than 350, and pH is 6.0); Improve stirring to 500 rpm, continue to stir for 30 minutes;

[0046] Then the resulting mixture slurry is dried with a mist drying tower, and the air inlet temperature is set to 220°C, the outlet air temperature is 150°C, the atomization speed is 60HZ, the feed flow rate is 0.3 cubic meters per hour, and the negative pressure is 300 Pa , dried, and the obtained solid powder was sieved into a particle size d50 of 200 microns, and the particle size was detec...

Embodiment 3

[0048] The preparation method of the pharmaceutical excipient of microcrystalline cellulose and guar gum compound chewable tablet comprises the following steps:

[0049] Add 500 kilograms of medical deionized water, then add 20 kilograms of dried guar gum of pharmaceutical grade, and stir with a SWFS-400 high-speed disperser at a stirring rate of 150 rpm;

[0050] After guar gum dissolves completely, add 100 kilograms of microcrystalline cellulose (water content is 45%, degree of polymerization is less than 350, and pH is 6.0); Improve stirring to 500 rpm, continue stirring for 30 minutes;

[0051] Then the resulting mixture slurry is dried with a spray drying tower, and the air inlet temperature is set to 250°C, the outlet air temperature is 150°C, the atomization speed is 80HZ, the feed flow rate is 0.2 cubic meters per hour, and the negative pressure is 300 Pa , dried, and the obtained solid powder was sieved into a particle size d50 of 200 microns, and the particle size wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com