A roller conveying line capable of shot blasting, cleaning and testing cylinder castings

A technology for detecting rollers and conveyor lines, which is applied to roller tables, conveyors, mechanical conveyors, etc., can solve problems such as difficulty in satisfying cylinder casting automation production lines, labor-intensive and time-consuming hoisting and handling, and difficulty in coordinating operations, etc. Achieve the effects of improving cleaning efficiency, compact and reasonable structure layout, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

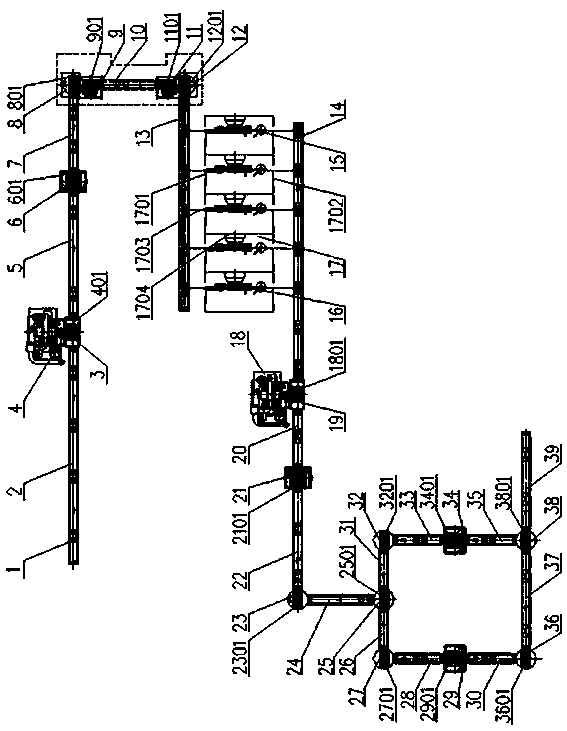

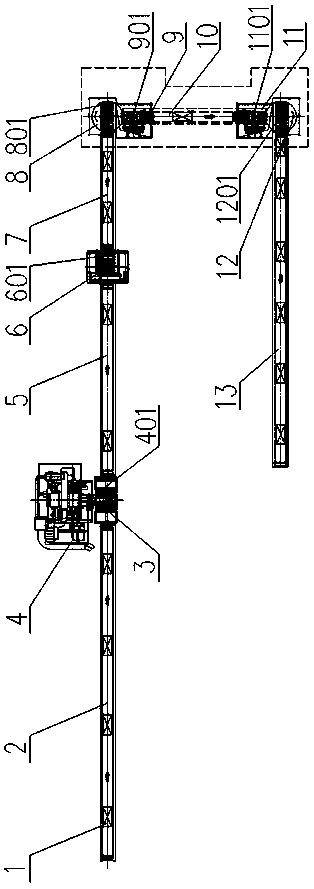

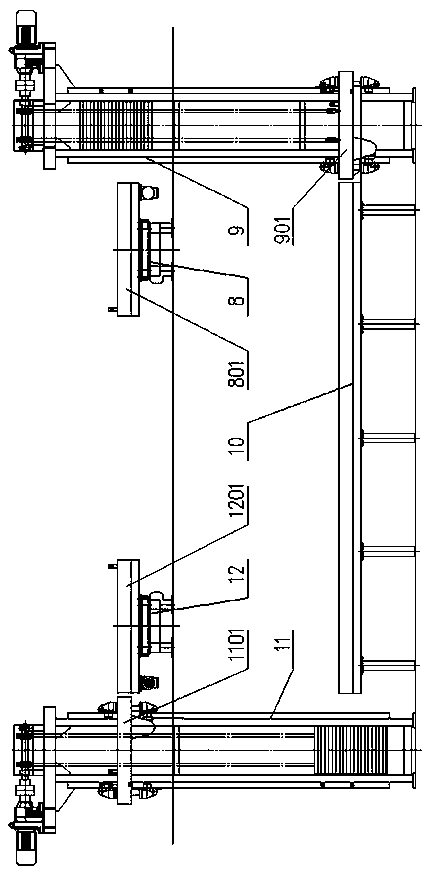

[0023] Referring to the accompanying drawings, the specific implementation is as follows:

[0024] A roller conveyor line capable of shot blasting, cleaning and testing cylinder castings, including the first roller conveyor line for rough shot blasting of cylinder 1 and underground cross-workshop transportation, and for cleaning cylinders The second roller conveying line for fine shot blasting and detection of body 1, and the cleaning workshop between the end of the first roller conveying line and the beginning of the second roller conveying line;

[0025] The first roller conveying line is sequentially provided with an upper roller table 2, a rough shot blasting machine roller table 3, a rough blasting roller table 5, a rough blasting roller table 7, and an underground cross-workshop roller table from the beginning to the end of the first roller conveyor line. 10 and roller table 13 before cleaning, one side of the rough shot blasting machine roller table 3 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com