A kind of production method of high-quality polyparaphenylene terephthalamide resin and ppd dissolution kettle

A technology of poly-p-phenylene terephthalamide and terephthaloyl chloride, which is applied in the direction of dissolution, dissolution, chemical instruments and methods, etc., and can solve the problems of compound solvent quality fluctuations, difficult control of molar ratio, and polymerization reaction temperature. Control and other issues, to achieve the effect of easy control of the total molar ratio, avoid repeated transfer, and reduce corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of production method of high-quality polyparaphenylene terephthalamide resin (PPTA), comprises the following steps:

[0039] (1) Mixed batch of NMP / CaCl2 composite solvent: first mix CaCl 2 Make it into an aqueous solution, then mix it with the solvent NMP, and remove the water after refining to obtain NMP / CaCl 2 Composite solvent (for the specific preparation process, please refer to patent 200810049483.9), under the condition of nitrogen blanketing, NMP / calcium chloride composite solvent, in the mixed batch tank at 95±5℃ for 3 days, relying on agitator and tank bottom pump Stir continuously and circulate, after batch mixing, the calcium chloride content is 8.0wt%, moisture 100PPm.

[0040] In order to prevent the moisture in the nitrogen from causing the moisture in the reaction system to exceed the standard and affect the reaction, the nitrogen index and dosage should be strictly controlled. The nitrogen dew point temperature must be lower than -70°C. Sligh...

Embodiment 2

[0048] A kind of production method of high-quality polyparaphenylene terephthalamide resin (PPTA), comprises the following steps:

[0049] (1) NMP / CaCl 2 Composite solvent mixed batch: NMP / calcium chloride composite solvent is not mixed batch, storage temperature is 95±5℃, calcium chloride content and moisture both fluctuate, calcium chloride content is 7.0-8.5%, moisture 100PPm; Nitrogen protection prevents the compound solvent from deteriorating;

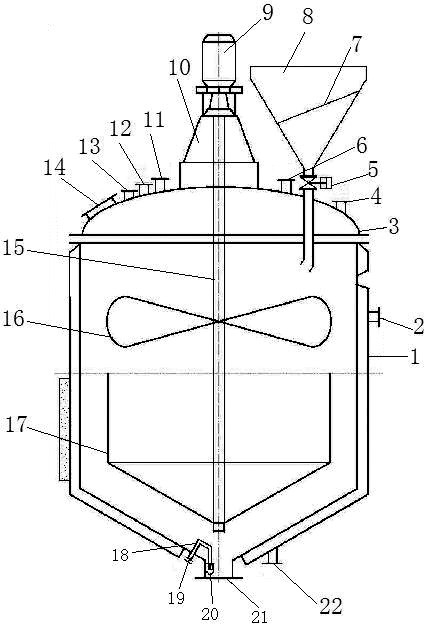

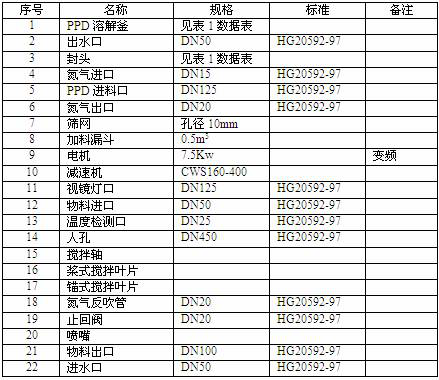

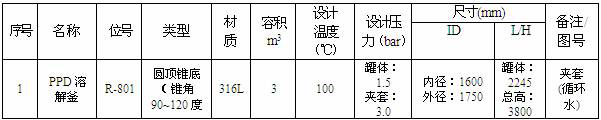

[0050] (2) Preparation of p-phenylenediamine (PPD) solution: under the condition of nitrogen blanketing, add 1920kg of the composite solvent into the PPD dissolution kettle, make the stirring shaft 15 stir at a speed of 50 rpm, and pour into the PPD dissolution kettle through the feeding funnel 8 Add 100kg of PPD inside, feed circulating water from the water inlet 22 to make the dissolution temperature in the kettle 60°C, and get the PPD solution after fully dissolving for 1 hour, open the discharge valve on the discharge port 21...

Embodiment 3

[0056] A kind of production method of high-quality polyparaphenylene terephthalamide resin (PPTA), comprises the following steps:

[0057] (1) NMP / CaCl 2 Composite solvent mixed batch: under the condition of nitrogen blanketing, the NMP / calcium chloride composite solvent is mixed in the mixed batch tank at 95±5°C for 3 days, and it is stirred by the agitator and the tank bottom pump. , the calcium chloride content is 8.0%, the water content is 100PPm, and nitrogen is added in the tank to protect it from deterioration of the compound solvent;

[0058](2) Preparation of p-phenylenediamine (PPD) solution: under the condition of nitrogen blanketing, add 1920 kg of the composite solvent into the PPD dissolution kettle, stir the stirring shaft 15 at a speed of 40 rpm, and dissolve into the PPD through the feeding funnel 8 Add 100kg PPD into the kettle, dissolve at a temperature of 30°C, and obtain a PPD solution after fully dissolving for 1 hour. Open the discharge valve on the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com