Desulfurized ash self-activating and solidifying material

A technology of consolidating materials and desulfurization ash, which is applied in cement production and other directions, can solve the problems of ecological environment damage in power plants and steel mills, and restrict the development of enterprises, and achieve the effects of saving land, saving energy, environmental protection, low cost, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

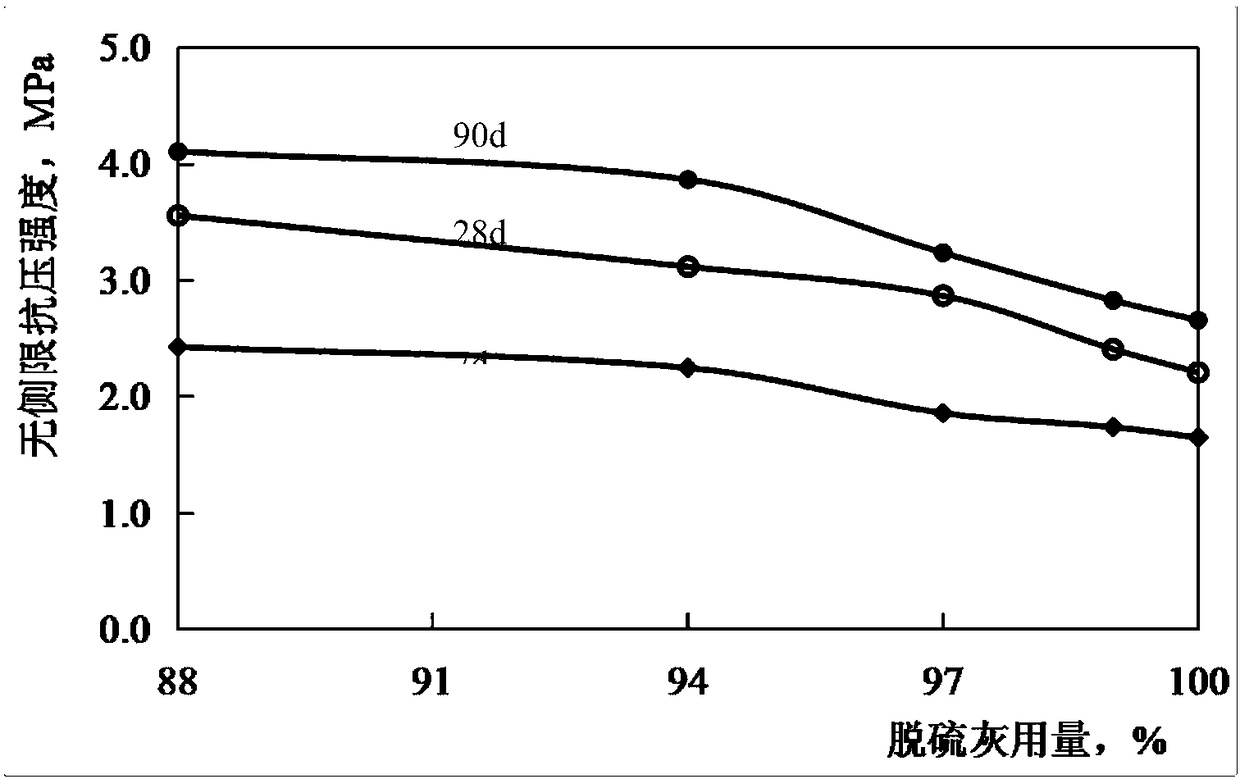

[0033] Desulfurization ash self-activation consolidation material strength: Weigh the desulfurization ash and phosphorous slag powder according to the design components in Table 1, carry out the compaction test, and determine the optimum moisture content and maximum dry density of the mixture (see Table 1), The specimens were molded at a controlled degree of compaction and their unconfined compressive strength was determined. The desulfurization ash comes from the sintering plant of the iron and steel enterprise. The unconfined compressive strength test is carried out according to the compaction degree of 95% by changing the content of the desulfurized ash. The specific results of the 7-day, 28-day and 90-day unconfined compressive strength are shown in the table 2 and figure 1 .

[0034] From Table 2 and figure 1 It can be seen from the performance index that when changing the content of desulfurization ash, its strength first increases and then decreases with the increase ...

Embodiment 2

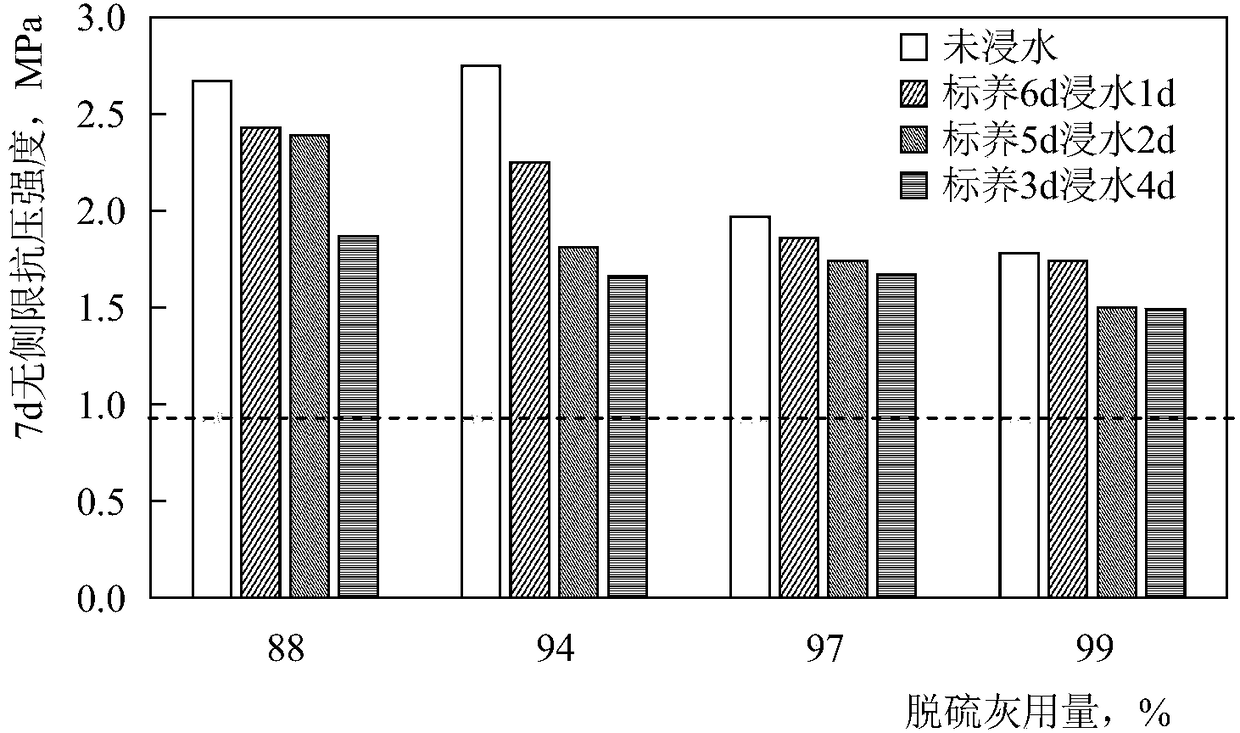

[0036] Water stability of desulfurized ash self-activated consolidation material: On the basis of Example 1, a test piece was molded according to a controlled degree of compaction and a 7-day water stability test was carried out. The desulfurization ash comes from the sintering plant of the iron and steel enterprise, and the unconfined compressive strength test piece is made according to the compaction degree of 95% by changing the content of the desulfurization ash. Experiments were carried out under different water immersion conditions, and the specific results of the 7d unconfined compressive strength measured afterwards are shown in Table 3.

[0037] From the performance indicators in Table 3, it can be seen that within the range of the content of desulfurization ash, the test block did not appear cracking, corrosion and collapse; at the same time, the minimum strength value of 7d water stability can reach 1.49MPa, and the strength can also meet Requirements for filling ma...

Embodiment 3

[0039] Frost resistance of desulfurized ash self-activated consolidation material: On the basis of Examples 1 and 2, a test piece with a size of Φ150mm×150mm was molded according to the controlled compaction degree, and the frost resistance test was carried out. When the specimens were cured to the age of 28 days, five freeze-thaw cycle tests were carried out. Record the mass and height of the specimen after each freeze-thaw, and measure the unconfined compressive strength of the specimen after the freeze-thaw cycle test according to the procedure (see Table 4).

[0040] From the performance indicators in Table 4, it can be seen that after the freeze-thaw cycle test, the unconfined compressive strength of the specimen at 28 days can still reach 1.5MPa and above, but some corner defects appear on the surface of some specimens. It can be seen that the actual application of desulfurization ash self-activation consolidation materials should fully consider the requirements of mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com