Unitary system special cement self-leveling terrace material

A cement and powder technology, which is applied in the field of self-leveling floor materials of high belite sulfoaluminate cement one-element system, can solve the problems of increasing management costs, difficulty in controlling the performance of self-leveling mortar, affecting application and promotion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The preparation method of the mortar powder of the present invention may include: weighing additives by weight, i.e. polymer latex powder, optional thickener, thixotropic agent, retarder, coagulant accelerator, defoamer and water reducer , mixed to obtain the additive mixture, and then mixed according to the ratio of 1 weight part of the additive and 2-4 weight parts (eg 3 weight parts) of sand, to prepare the additive premix. Then, weigh high belite sulfoaluminate cement, ground slag powder, heavy calcium powder, remaining sand, said premix, and other additive components not included in the additive premix by weight ratio, The mortar powder of the present invention can be prepared by mixing evenly. Mixing can be done with a conventional dry blender.

[0061] In the present invention, the high belite cement one-component cementitious material system is used to replace the traditional aluminate cement-portland cement-gypsum three-component cementitious material system, ...

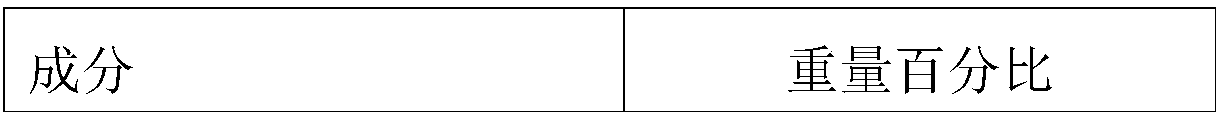

Embodiment 1

[0075] The formula shown in Table 1 below takes by weighing polymer latex powder, cellulose ether, dipitan, citric acid, tartaric acid, lithium carbonate, defoamer and polycarboxylate water reducer, and mixes to obtain the additive mixture, with 1 weight part This additive mixture was mixed with 3 parts by weight of sand to obtain an additive premix. Weigh high belite sulfoaluminate cement, ground slag powder, heavy calcium powder and the remaining sand according to the formula shown in Table 1, and mix them with the additive premix evenly to prepare mortar powder. Mixing is performed using a dry blender.

[0076] The mortar powder is stirred and mixed with water according to the ratio of 1 weight part of mortar powder: 0.21 weight part of water to form mortar.

[0077] Table 1

[0078]

[0079]

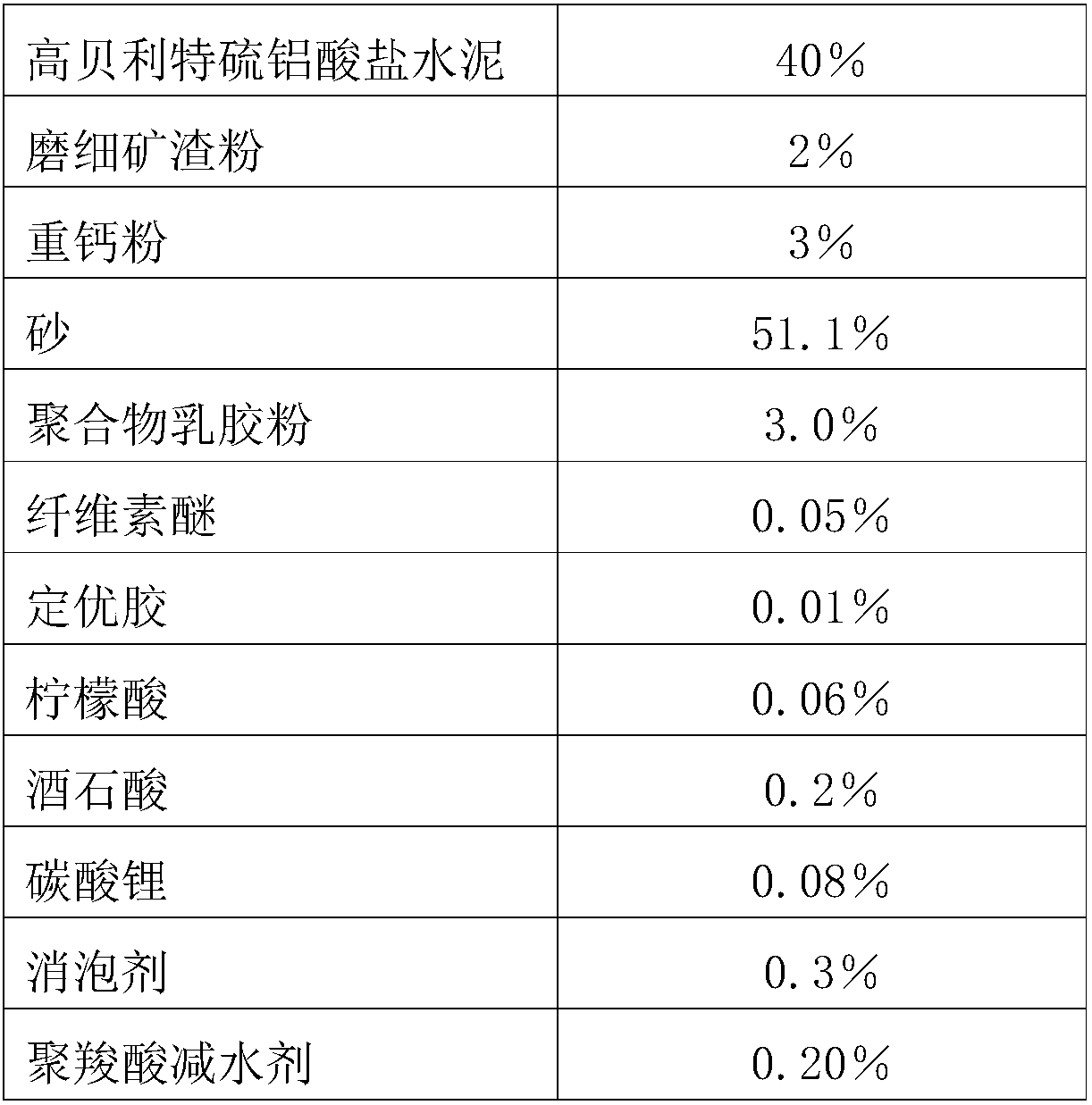

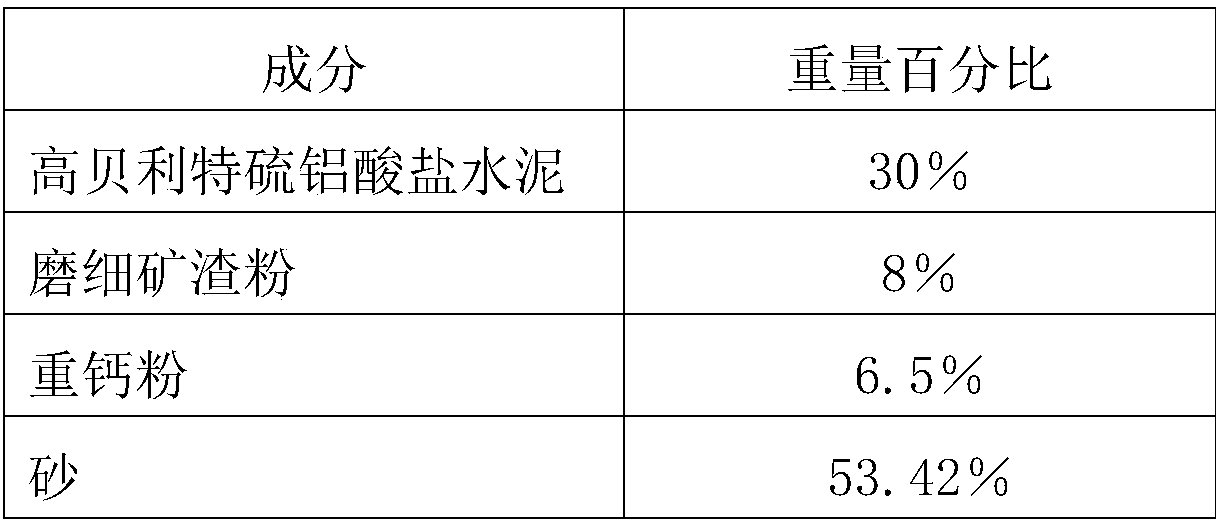

Embodiment 2

[0081] Formula shown in Table 2 below takes by weighing polymer latex powder, cellulose ether, citric acid, tartaric acid, lithium sulfate, lithium carbonate, defoamer and polycarboxylate water reducer, mixes to obtain additive mixture, with 1 weight part of the The additive mixture was mixed with 3 parts by weight of sand to obtain an additive premix. Weigh high belite sulfoaluminate cement, ground slag powder, heavy calcium powder and the remaining sand according to the formula shown in Table 1, and mix them evenly with the additive premix to prepare mortar powder. Mixing is performed using a dry blender.

[0082] The mortar powder is stirred and mixed with water according to the ratio of 1 weight part of mortar powder: 0.20 weight part of water to form mortar.

[0083] Table 2

[0084]

[0085]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com