Cable material containing special PVC calcium powder and preparation method thereof

A cable material and calcium powder technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of affecting processing and performance, poor quality of plastic products, poor thermal stability, etc. Oxidative degradation, improved heat resistance, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a cable material comprising calcium powder special for PVC, comprising the steps of:

[0028] (1) Ingredients: Take the following raw materials in parts by weight: 30-80 parts of polyvinyl chloride resin, 10-20 parts of PVC special calcium powder, 2-3 parts of dispersant, 5-8 parts of stabilizer, 2 parts of lubricant ~3 parts, 10~20 parts of plasticizer, 2~3 parts of antioxidant;,

[0029] (2) Refining: Fully mix the raw materials in step (1), and refine after stirring evenly; the fineness of refining is less than or equal to 80 μm;

[0030] (3) Kneading: knead the raw materials after refining in step (2) in a kneader for 5-10 minutes; the kneading temperature is controlled at 60-75°C;

[0031] (4) Extrusion: Extrude the kneaded raw materials in the extruder; the extrusion temperature is controlled at 155-180°C;

[0032] (5) Refining plastic: control the temperature at 160-175°C, refining plastic to obtain finished products;

[0033] Further, t...

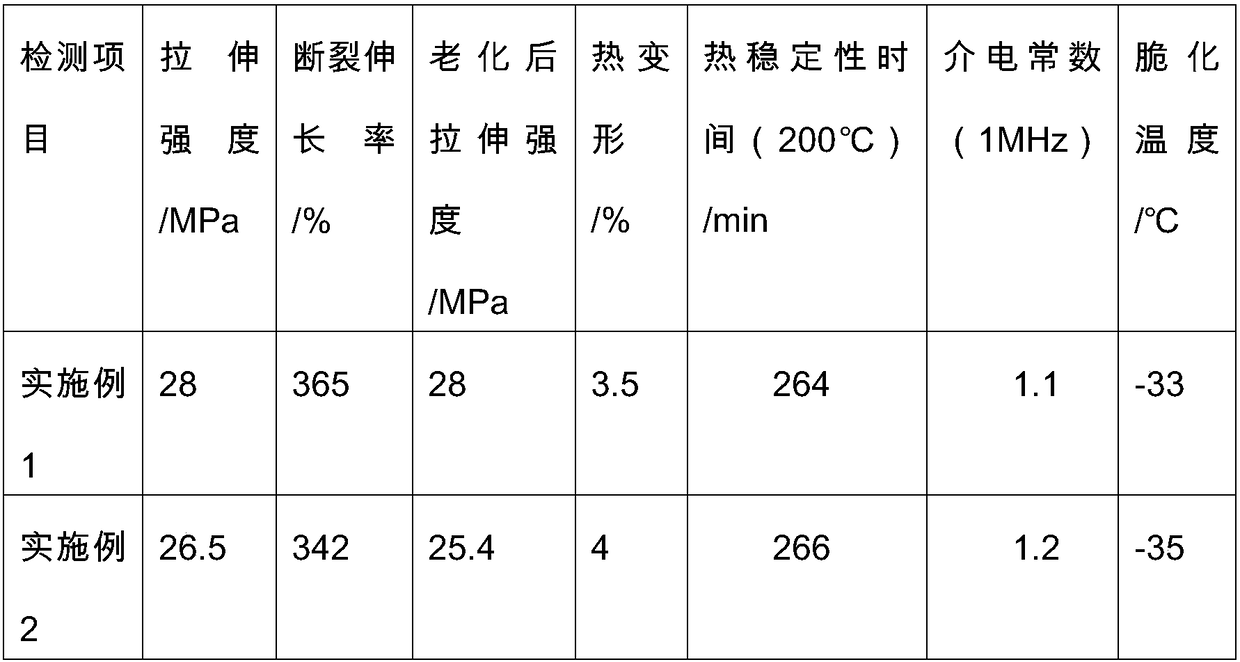

Embodiment 1

[0036] The processing technology of the wire and cable sheath based on nano-calcium carbonate comprises the following steps:

[0037] (1) batching; Get the raw material of following parts by weight: 58 parts of polyvinyl chloride resins, 15 parts of superfine calcium carbonates, 2 parts of dispersants, 5 parts of stabilizers, 3 parts of lubricants, 15 parts of plasticizers, Oxidant 2 parts

[0038] (2) refining; fully mixing the raw materials in the step (1), stirring evenly and then refining; the refining fineness is equal to 65 μm;

[0039] (3) kneading; the raw materials after step (2) refining were meshed in a kneader for 10 minutes; the kneading temperature was controlled at 65°C;

[0040] (4) Extrusion; extrude the kneaded raw materials in the extruder; the extrusion temperature is controlled at 170°C;

[0041] (5) Refining plastic; control the temperature at 165 ° C, refining plastic, to obtain finished products.

Embodiment 2

[0043] The processing technology of the wire and cable sheath based on nano-calcium carbonate comprises the following steps:

[0044] (1) batching; Get the raw material of following parts by weight: 58 parts of polyvinyl chloride resins, 15 parts of common heavy calcium carbonates, 2 parts of dispersants, 5 parts of stabilizers, 3 parts of lubricants, 15 parts of plasticizers, Antioxidant 2 parts

[0045] (2) refining; fully mixing the raw materials in the step (1), stirring evenly and then refining; the refining fineness is equal to 65 μm;

[0046] (3) kneading; the raw materials after step (2) refining were meshed in a kneader for 10 minutes; the kneading temperature was controlled at 65°C;

[0047](4) Extrusion; extrude the kneaded raw materials in the extruder; the extrusion temperature is controlled at 170°C;

[0048] (5) Refining plastic; control the temperature at 165 ° C, refining plastic, to obtain finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com