A gas-liquid dual-purpose direct methanol fuel cell

A methanol fuel cell, methanol technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as insufficient temperature, and achieve the effects of low production cost, high flexibility, and reduced osmotic voltage loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

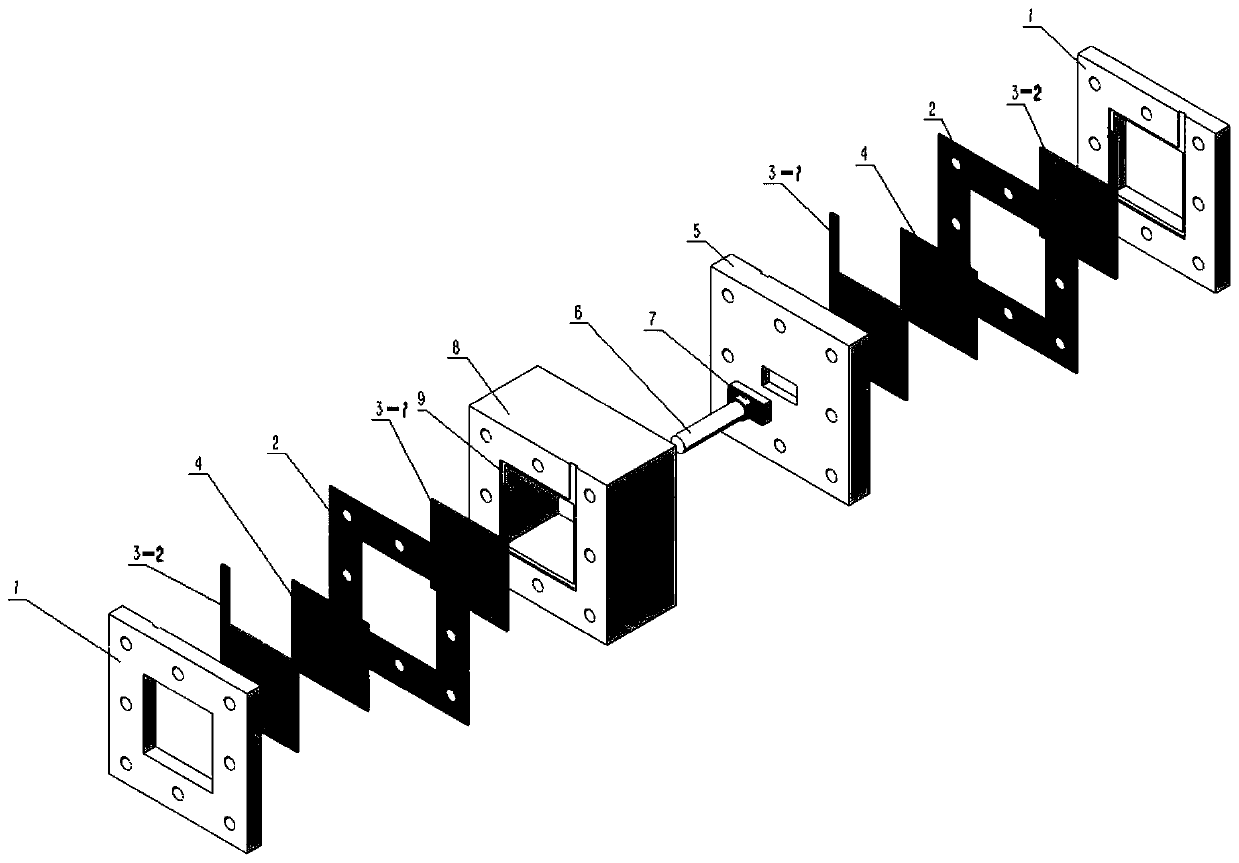

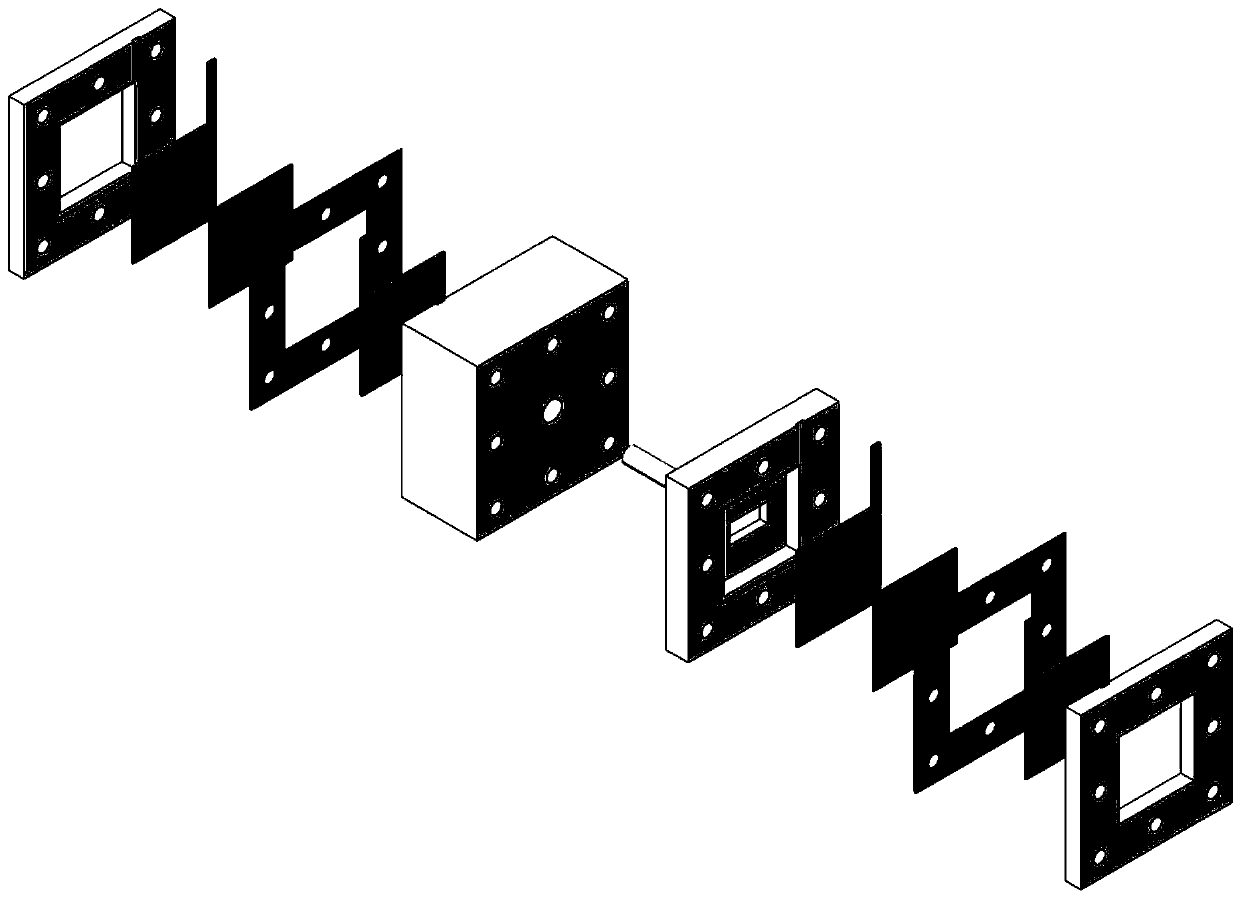

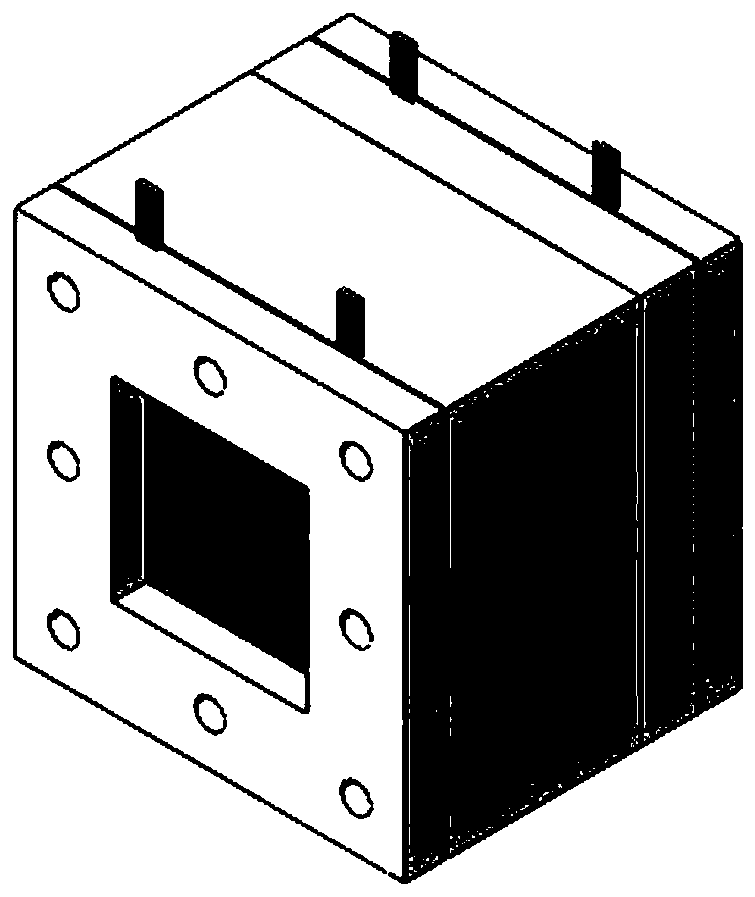

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Direct methanol fuel cell is a high-efficiency power generation device that directly converts electrochemical reaction energy into electrical energy. When the direct methanol fuel cell is working, the aqueous methanol solution in the anode flow field passes through the diffusion layer through diffusion, reaches the anode catalytic layer, and undergoes oxidation reaction to generate CO 2 Gas, protons and electrons, protons reach the cathode catalytic layer through the proton exchange membrane, and electrons reach the cathode catalytic layer through the external circuit, and the two undergo a reduction reaction with oxygen that reaches the cathode catalytic layer through natural convection to generate the product H 2 O. Among them, the proton exchange membrane in the membrane electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com