Method for preparing crosslinked elastomer capable of being reprocessed by utilizing transamination

A cross-linked elastomer and reprocessing technology, which is applied in the field of functional materials, can solve problems such as insufficiency, and achieve the effects of environmental protection, simple and efficient modification methods, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

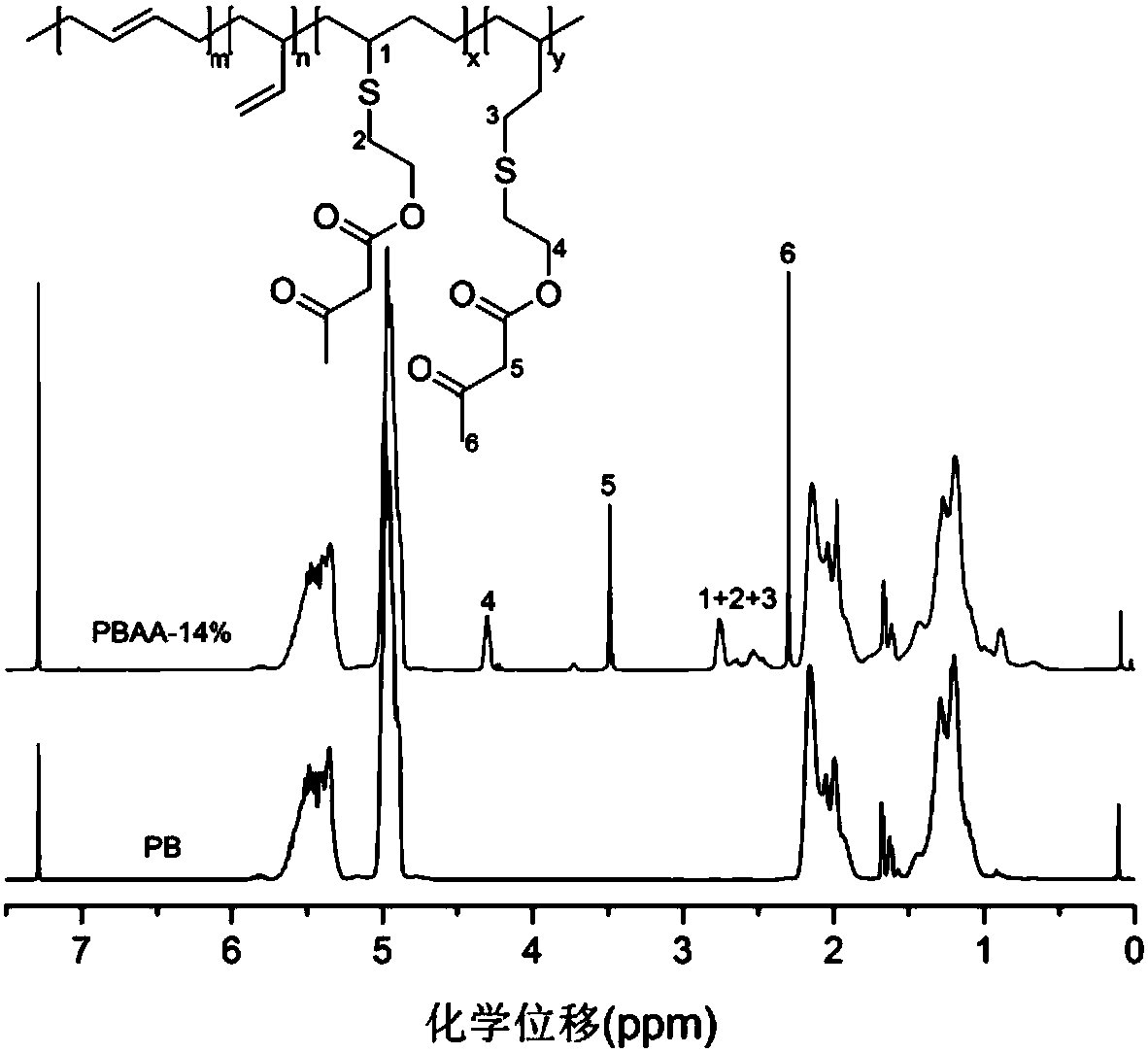

[0038] (1) Taking PBAA-14% molar content of acetoacetyl group as an example, first dissolve 10g of butadiene rubber in 200mL of dichloromethane, add 2g of mercaptoethanol and 0.1g of initiator I907, and mix well. Then keep stirring and place under UV lamp (254nm, 100W) for 8h. After the reaction was completed, the ultraviolet lamp was removed, and then 3.3 g of diketene was added to the solution to continue the reaction for 1 h, and then reflux for 4 h. Finally, the solution was poured into 2L of absolute ethanol for precipitation, the precipitate was washed twice with absolute ethanol, and dried to constant weight. pass 1 HNMR characterizes and modifies the product quantitatively, and the important peak assignment results are as follows figure 1 shown. It can be seen from the calculation that 13.7 mol% of the double bonds in the butadiene rubber are modified into acetoacetyl groups, which is close to the feed ratio of 14 mol%, which shows the high efficiency of the modific...

Embodiment 2

[0043] (1) Obtain modified butadiene rubber PBAA-14% by the method of operation (1) in embodiment 1.

[0044] (2) Prepare the cross-linked film according to the method of operation (2) in Example 1, only need to replace 1,2-bis(2-aminoethoxy)ethane with ethylenediamine, and add with the same molar amount. According to the GB / T 528-2009 standard, the stress-strain curve is obtained as Figure 4As shown, the strain is 108%, the stress reaches 7.8MPa, and the toughness is 420MJ / m 3 .

[0045] (3) carry out reprocessing by the method of operation (3) among the embodiment 1.

[0046] (4) By the same test as in Example 1, the analysis results can draw the following conclusions: the reprocessed film is still a cross-linked network structure, has good solvent resistance, and has good reprocessing performance. After three times of reprocessing, the toughness is 320MJ / m 3 , reaching 76% of the original performance.

Embodiment 3

[0048] (1) Obtain modified butadiene rubber PBAA-14% by the method of operation (1) in embodiment 1.

[0049] (2) prepare the cross-linked film by the method of operation (2) in embodiment 1, only need to replace 1,2-bis(2-aminoethoxy)ethane with p-xylylenediamine, with the same molar amount join in. According to the GB / T 528-2009 standard, the stress-strain curve is obtained as Figure 4 As shown, the strain is 102%, the stress reaches 11.3MPa, and the toughness is 690MJ / m 3 .

[0050] (3) carry out reprocessing by the method of operation (3) among the embodiment 1.

[0051] (4) The reprocessed film is still a cross-linked network structure, has good solvent resistance, and has good reprocessing performance. After three times of reprocessing, the toughness is 550MJ / m 3 , reaching 79% of the original performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

| toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com