Strain measuring method based on SEM in-situ imaging system

A technology of strain measurement and imaging system, applied in the field of strain measurement, to achieve high definition, high reliability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

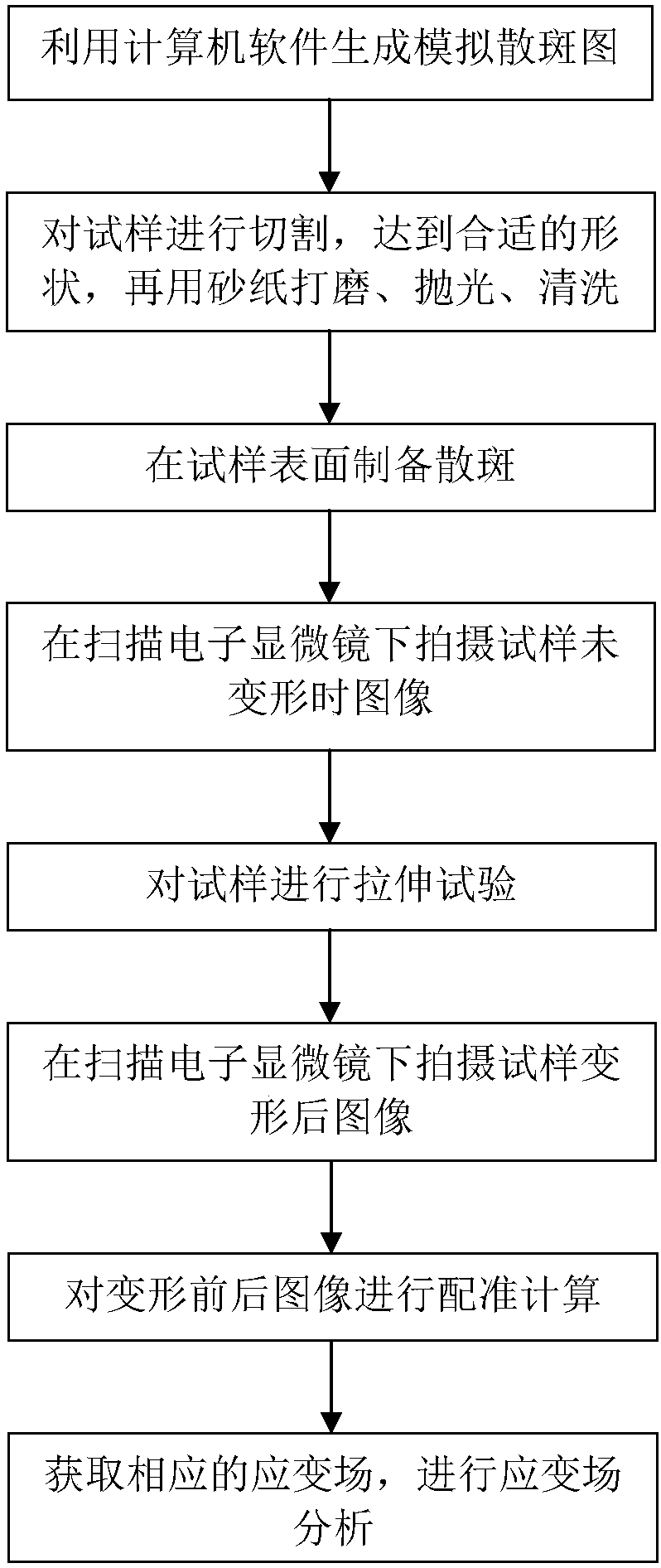

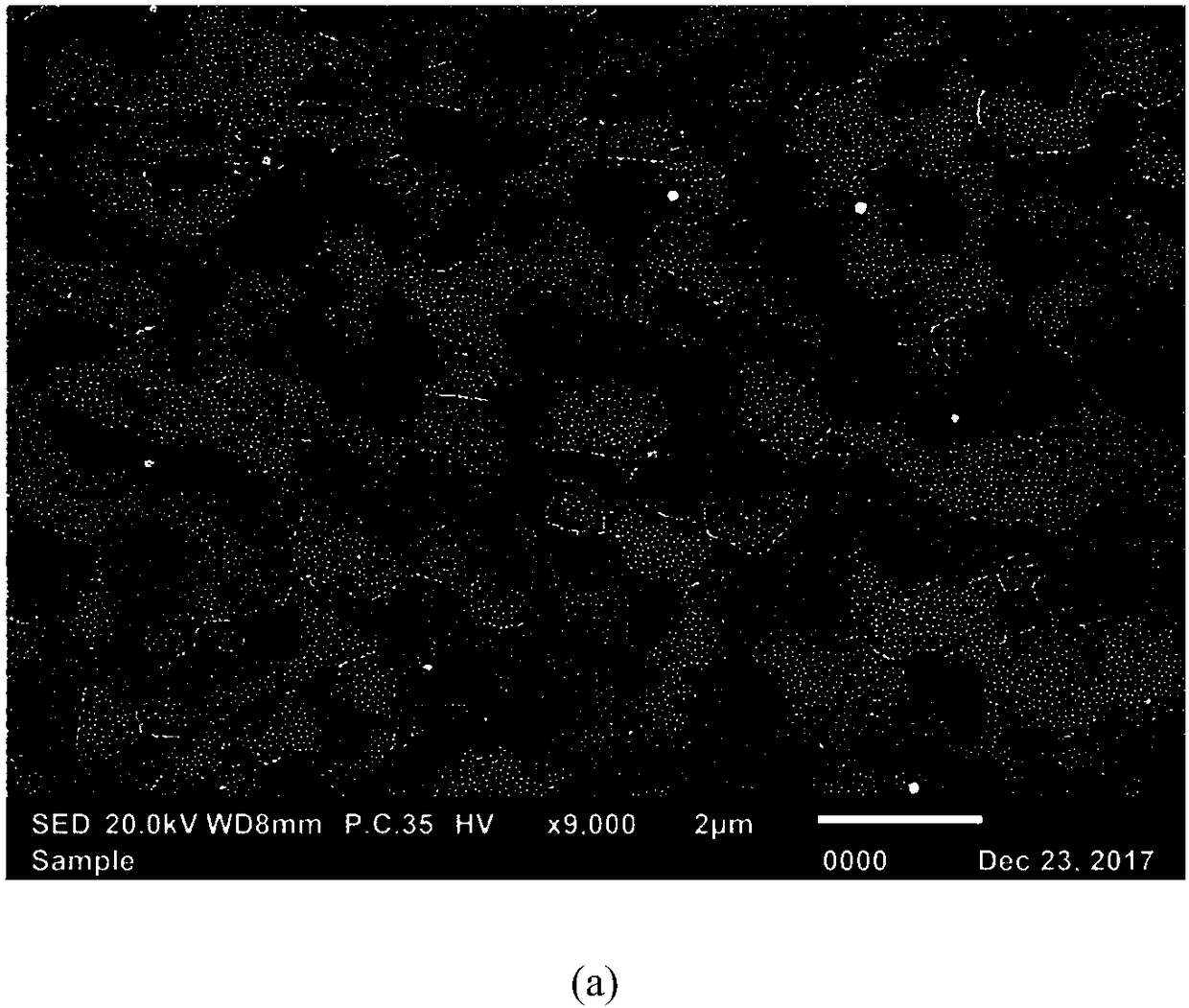

[0034] In this example, a tensile test of a steel material is carried out, and its deformation is analyzed after a tensile test, and the cloud diagram of the axial displacement and axial strain of the specimen is obtained, and the calculation error used to characterize the digital image is given. residual image. The specific implementation is as follows:

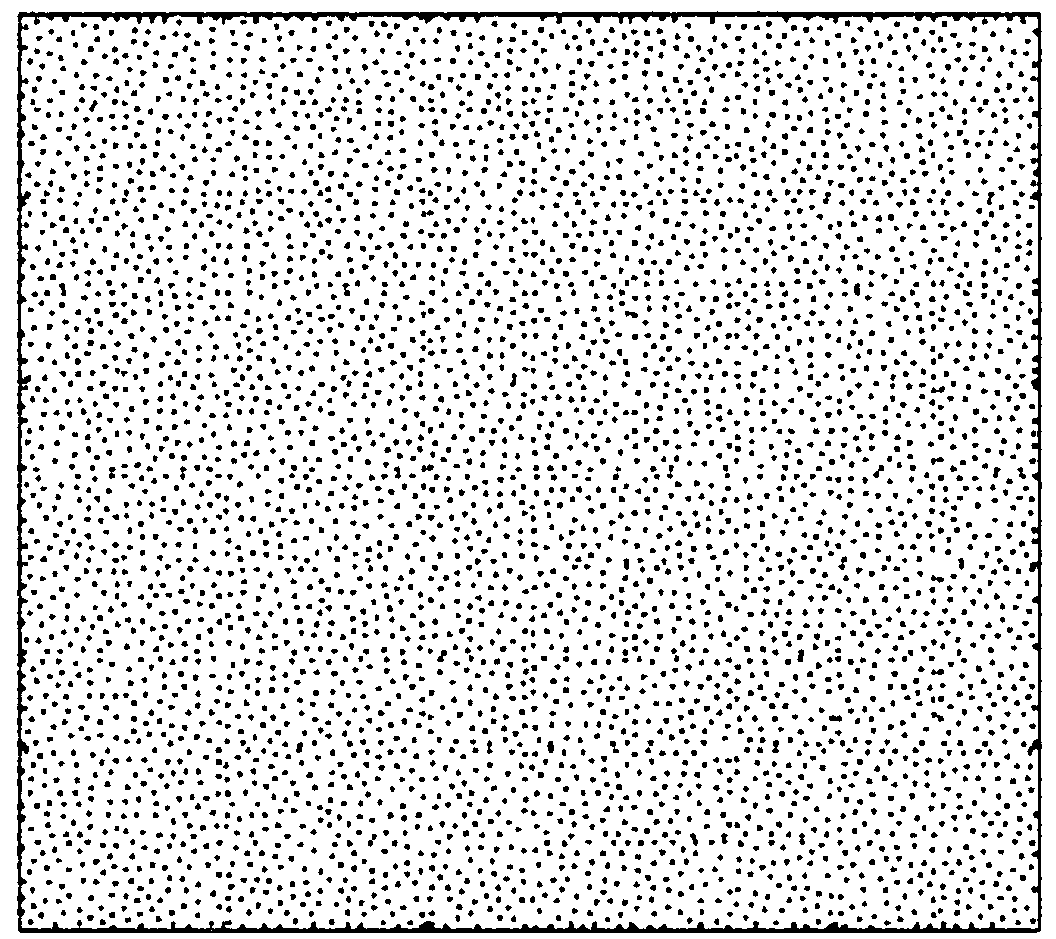

[0035] First, a series of randomly distributed points are generated within the specified size by MATLAB software, and the distance between these random points is required to be not less than 60nm to ensure that the distribution of speckle points is uniform, and these randomly distributed points are used as the center to generate a 20nm diameter speckle. circle, the diameter of the speckle is small, and the gray gradient between adjacent pixels is large, which is conducive to increasing the gray gradient of the speckle image, thereby reducing the random error related to the digital image. The obtained image is figure 2 The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com