Manganese dioxide/carbon cloth composite material as well as preparation method and application thereof and air purification device

An air purification device, manganese dioxide technology, applied in the field of air purification, can solve the problems of low conversion rate, unsatisfactory formaldehyde degradation effect, slow formaldehyde degradation rate, etc., achieve high degradation efficiency and conversion rate, good thermoelectric performance, The effect of efficient formaldehyde degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0033] The first embodiment of the present invention provides a method for preparing a manganese dioxide / carbon cloth composite material, comprising:

[0034] S1, providing carbon cloth and permanganate solution, the concentration of the permanganate solution is 10mmol / L to 300mmol / L; and

[0035] S2, disposing the carbon in the permanganate solution, and placing it under the condition of 0° C. to 80° C. for 0.5 h to 48 h to obtain the manganese dioxide / carbon cloth composite material.

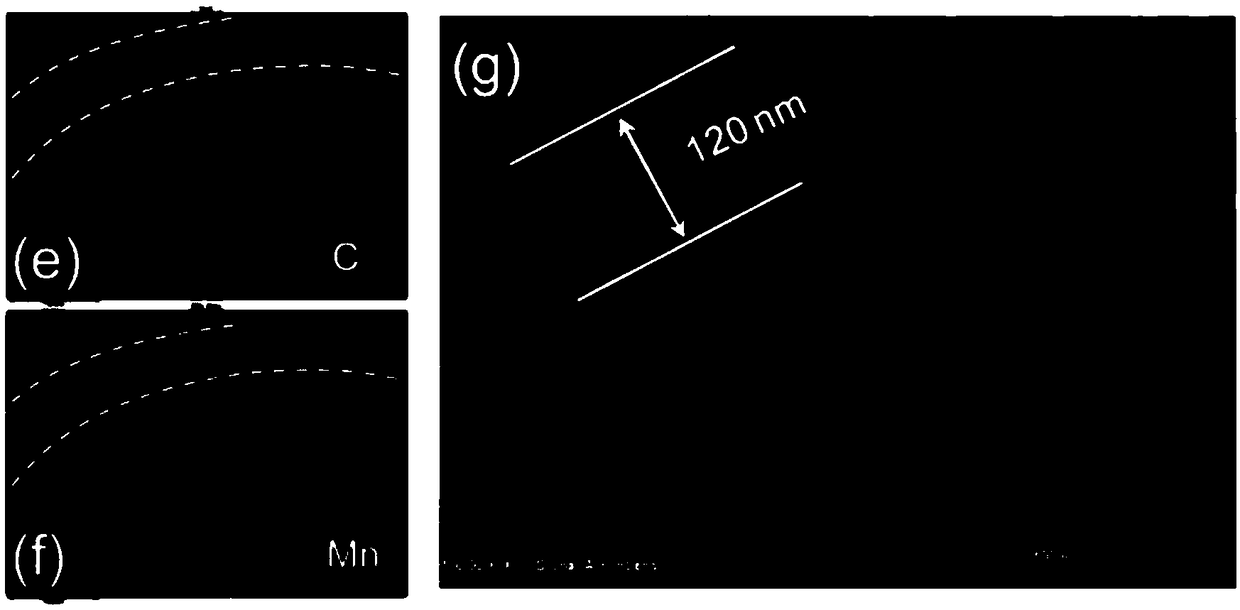

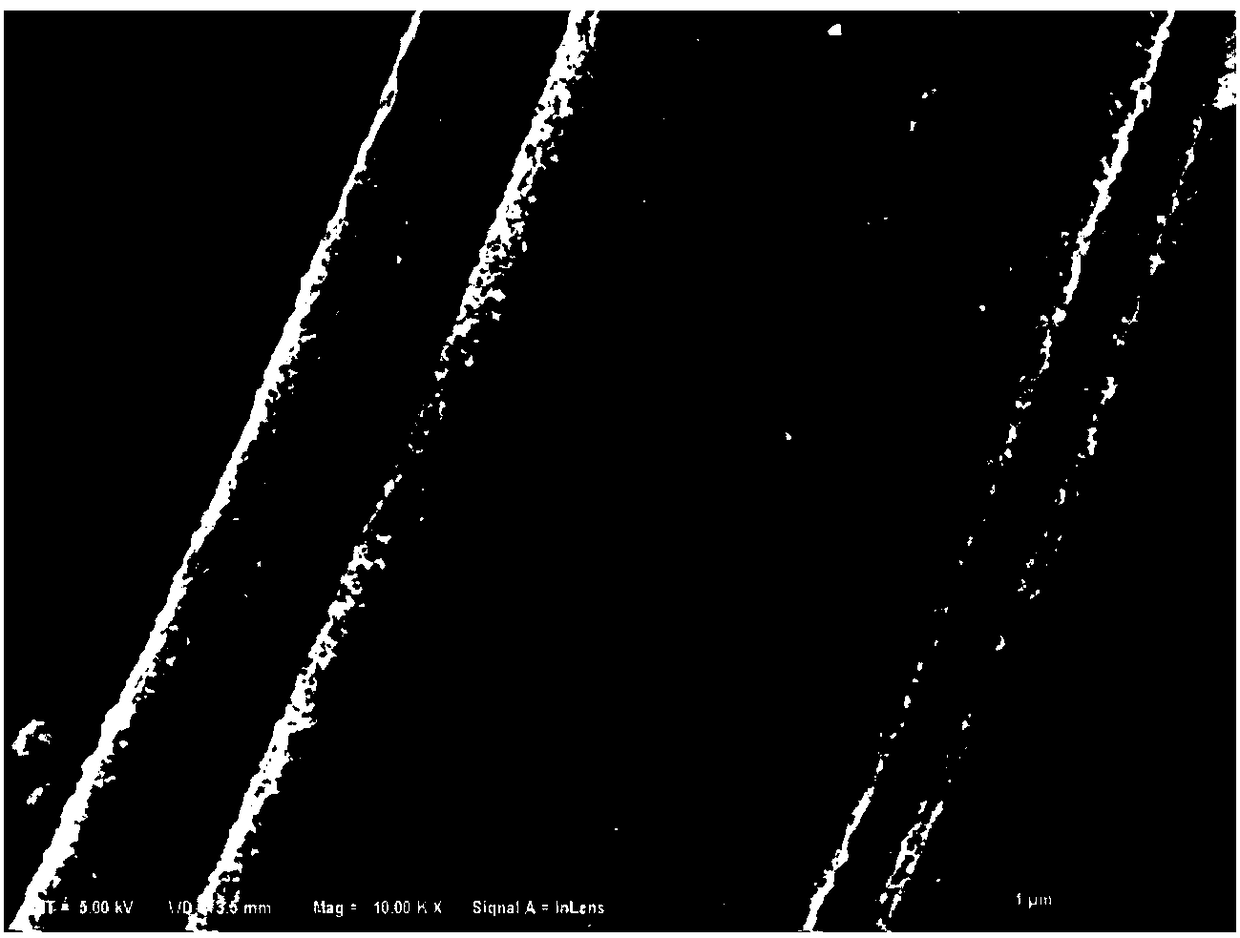

[0036] In the embodiment of the present invention, manganese dioxide is loaded on the carbon cloth by performing an in-situ reaction on the carbon cloth to form the manganese dioxide / carbon cloth composite material, wherein the carbon fiber between the manganese dioxide and the carbon cloth An efficient heat transfer interface is formed, and the heat generated by the manganese dioxide / carbon cloth composite material in the electrified state can be quickly transferred to the manganese dioxide, ...

Embodiment 1

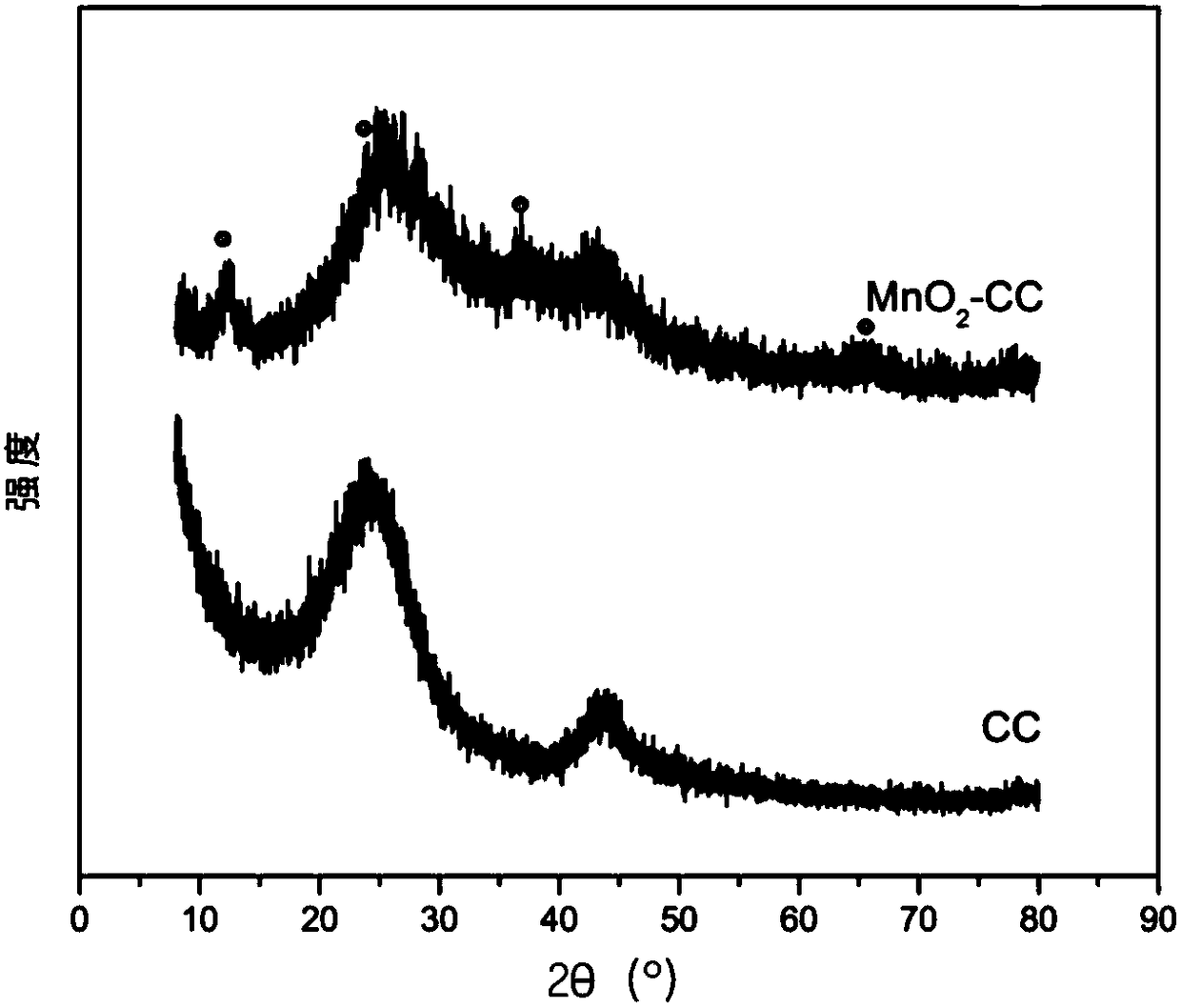

[0050] Take 1 mg potassium permanganate (KMnO 4 ) was dissolved in 70 mL deionized water to form KMnO 4 solution, and then a piece of carbon cloth (denoted as CC) with a size of 4cm×4cm was immersed in the KMnO 4 solution, and the reaction temperature was kept at 60°C for 5 hours, and finally the carbon cloth was taken out, washed with deionized water and dried at 105°C to obtain the manganese dioxide / carbon cloth composite material, denoted as MnO 2 -CC. Observing the manganese dioxide / carbon cloth composite material, it was found that the manganese dioxide / carbon cloth composite material was intact and undamaged, and the manganese dioxide / carbon cloth composite material was randomly twisted without fracture or slag dropping.

[0051] For CC and MnO 2 -CC conducts formaldehyde degradation experiment:

[0052] in MnO 2 -Copper electrodes are set at opposite ends of the CC, and the MnO 2 -CC was placed in an 800mL stainless steel reactor at 25°C for 30min without electri...

Embodiment 2

[0054] Take 0.5mg potassium permanganate (KMnO 4 ) was dissolved in 70 mL deionized water to form KMnO 4 solution, and then a piece of carbon cloth with a size of 4 cm × 4 cm was immersed in the KMnO 4 solution, and the reaction temperature was kept at 60°C for 5 hours, and finally the carbon cloth was taken out, washed with deionized water and dried at 105°C to obtain the manganese dioxide / carbon cloth composite material. Observing the manganese dioxide / carbon cloth composite material, it was found that the manganese dioxide / carbon cloth composite material was intact and undamaged, and the manganese dioxide / carbon cloth composite material was randomly twisted without fracture or slag dropping.

[0055] Adopt the method identical with embodiment 1 to carry out formaldehyde degradation experiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com