Ni-B-La catalyst for bio-oil catalytic reforming hydrogen production and preparation method thereof

A catalytic reforming, ni-b-la technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Reforming catalyst deactivation and other problems, to achieve the effect of mature and reliable preparation process, good anti-sintering and anti-carbon performance, high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

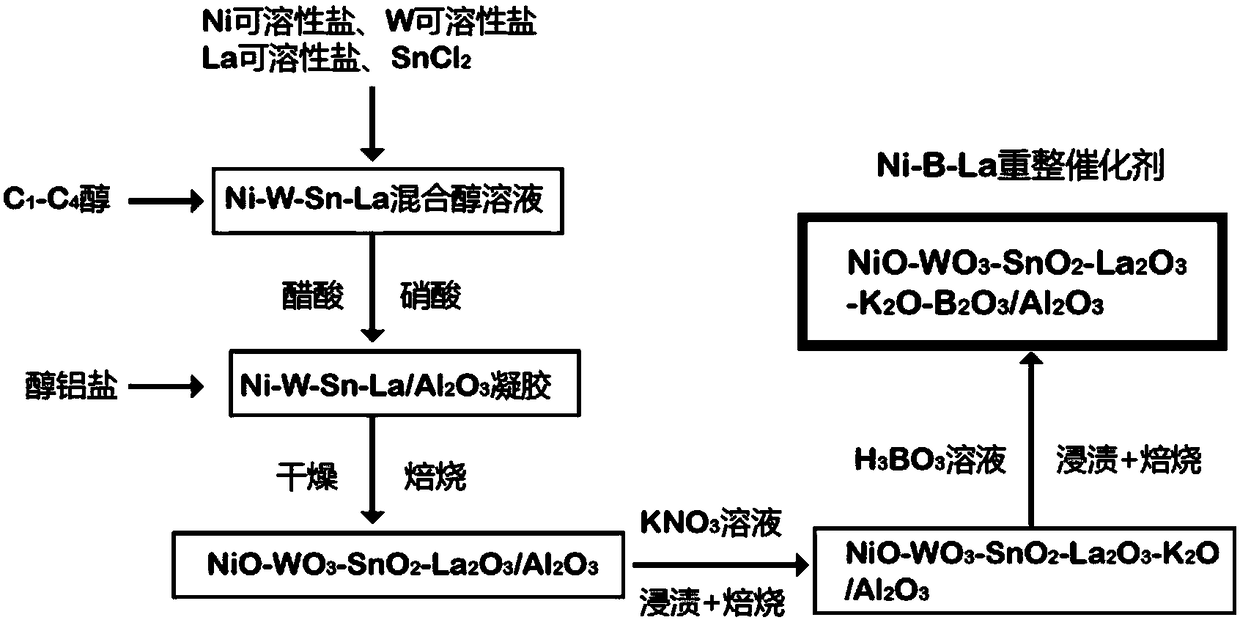

Method used

Image

Examples

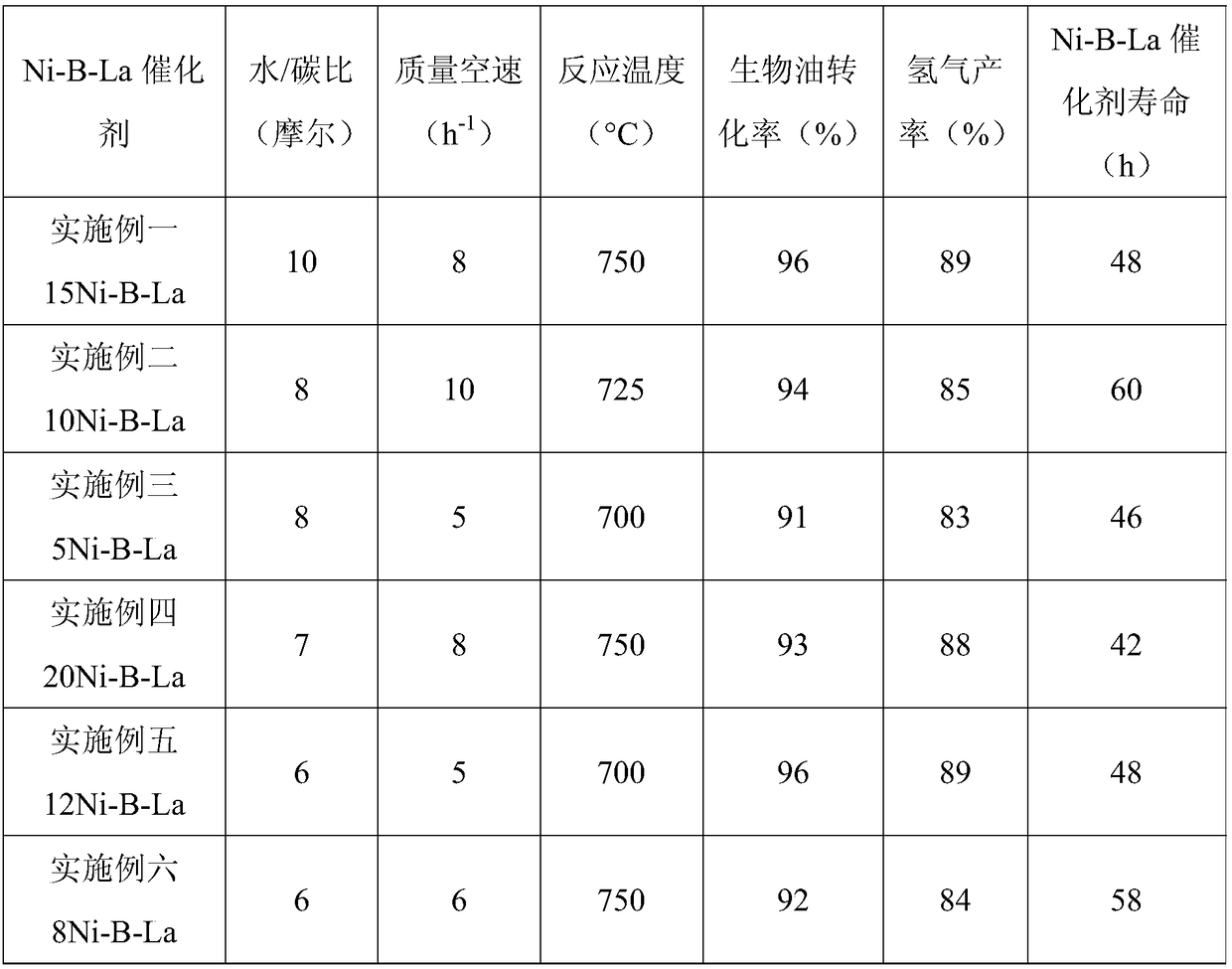

Embodiment 1

[0032] A kind of Ni-B-La catalyst that this embodiment proposes is used for bio-oil catalytic reforming hydrogen production, and it comprises catalyst active component, catalyst auxiliary agent and catalyst carrier, and catalyst active component is Ni, and its weight is Ni- 15% of the total weight of B-La catalyst; catalyst promoter is La 2 o 3 、WO 3 , SnO 2 、K 2 O and B 2 o 3 , La 2 o 3 The weight is 10% of the total weight of Ni-B-La catalyst, WO 3 The weight is 3% of the total weight of Ni-B-La catalyst, SnO 2 The weight is 1% of the total weight of Ni-B-La catalyst, K 2 The weight of O is 0.2% of the total weight of Ni-B-La catalyst, B 2 o 3 The weight of the Ni-B-La catalyst is 1% of the total weight; the catalyst support is Al 2 o 3 , whose weight is the balance, namely Al 2 o 3 The weight of Ni-B-La catalyst is 69.8% of the total weight.

[0033] In this Ni-B-La catalyst, the catalyst promoter La 2 o 3 The addition of can provide mobile lattice oxygen ...

Embodiment 2

[0047] A kind of Ni-B-La catalyst that this embodiment proposes is used for bio-oil catalytic reforming hydrogen production, and it comprises catalyst active component, catalyst auxiliary agent and catalyst carrier, and catalyst active component is Ni, and its weight is Ni- 10% of the total weight of B-La catalyst; catalyst promoter is La 2 o 3 、WO 3 , SnO 2 、K 2 O and B 2 o 3 , La 2 o 3 The weight is 12% of the total weight of Ni-B-La catalyst, WO 3 The weight is 1% of the total weight of Ni-B-La catalyst, SnO 2 The weight is 2% of the total weight of the Ni-B-La catalyst, K 2 The weight of O is 0.1% of the total weight of Ni-B-La catalyst, B 2 o 3 The weight of the Ni-B-La catalyst is 2% of the total weight; the catalyst support is Al 2 o 3 , whose weight is the balance, namely Al 2 o 3 The weight of Ni-B-La catalyst is 72.9% of the total weight.

[0048] The preparation method of the Ni-B-La catalyst that is used for bio-oil catalytic reforming hydrogen prod...

Embodiment 3

[0060] A kind of Ni-B-La catalyst that this embodiment proposes is used for bio-oil catalytic reforming hydrogen production, and it comprises catalyst active component, catalyst auxiliary agent and catalyst carrier, and catalyst active component is Ni, and its weight is Ni- 5% of the total weight of B-La catalyst; catalyst promoter is La 2 o 3 、WO 3 , SnO 2 、K 2 O and B 2 o 3 , La 2 o 3 The weight is 15% of the total weight of Ni-B-La catalyst, WO 3 The weight is 2% of the total weight of Ni-B-La catalyst, SnO 2 The weight is 1% of the total weight of Ni-B-La catalyst, K 2 The weight of O is 0.5% of the total weight of Ni-B-La catalyst, B 2 o 3 The weight of the Ni-B-La catalyst is 0.6% of the total weight; the catalyst support is Al 2 o 3 , whose weight is the balance, namely Al 2 o 3 The weight of Ni-B-La catalyst is 75.9% of the total weight.

[0061] The preparation method of the Ni-B-La catalyst that is used for bio-oil catalytic reforming hydrogen product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com