Insulation-type fire-proof door for subway tunnel

An isolation type, fire-resistant door technology, applied in the field of fire-resistant doors, can solve the problems of poor fire-proof and heat-insulating properties of hollow boards, and achieve the effects of reducing wear, strong flame retardancy, and accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

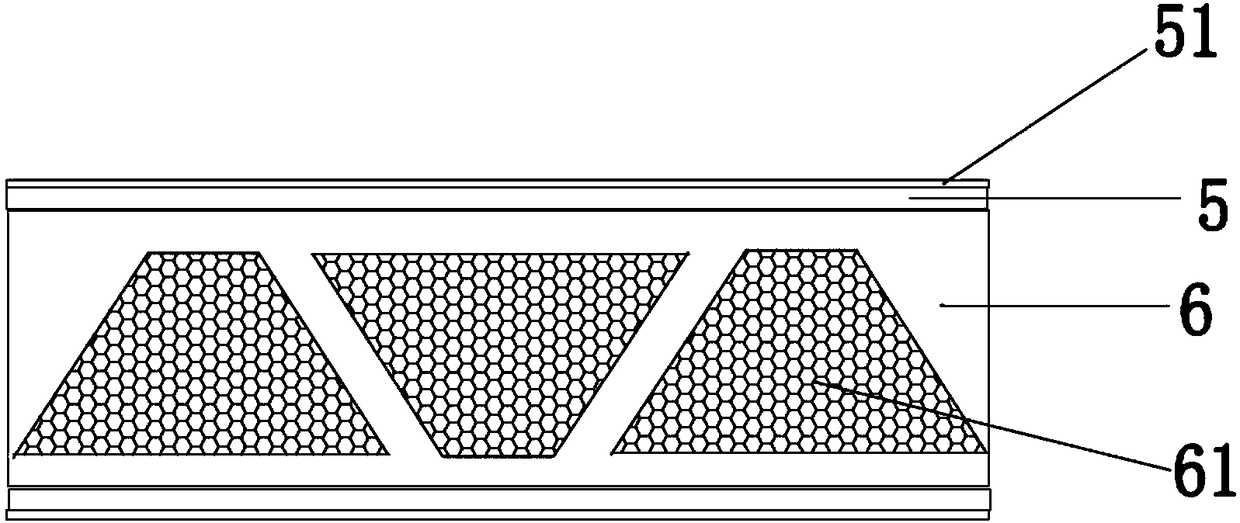

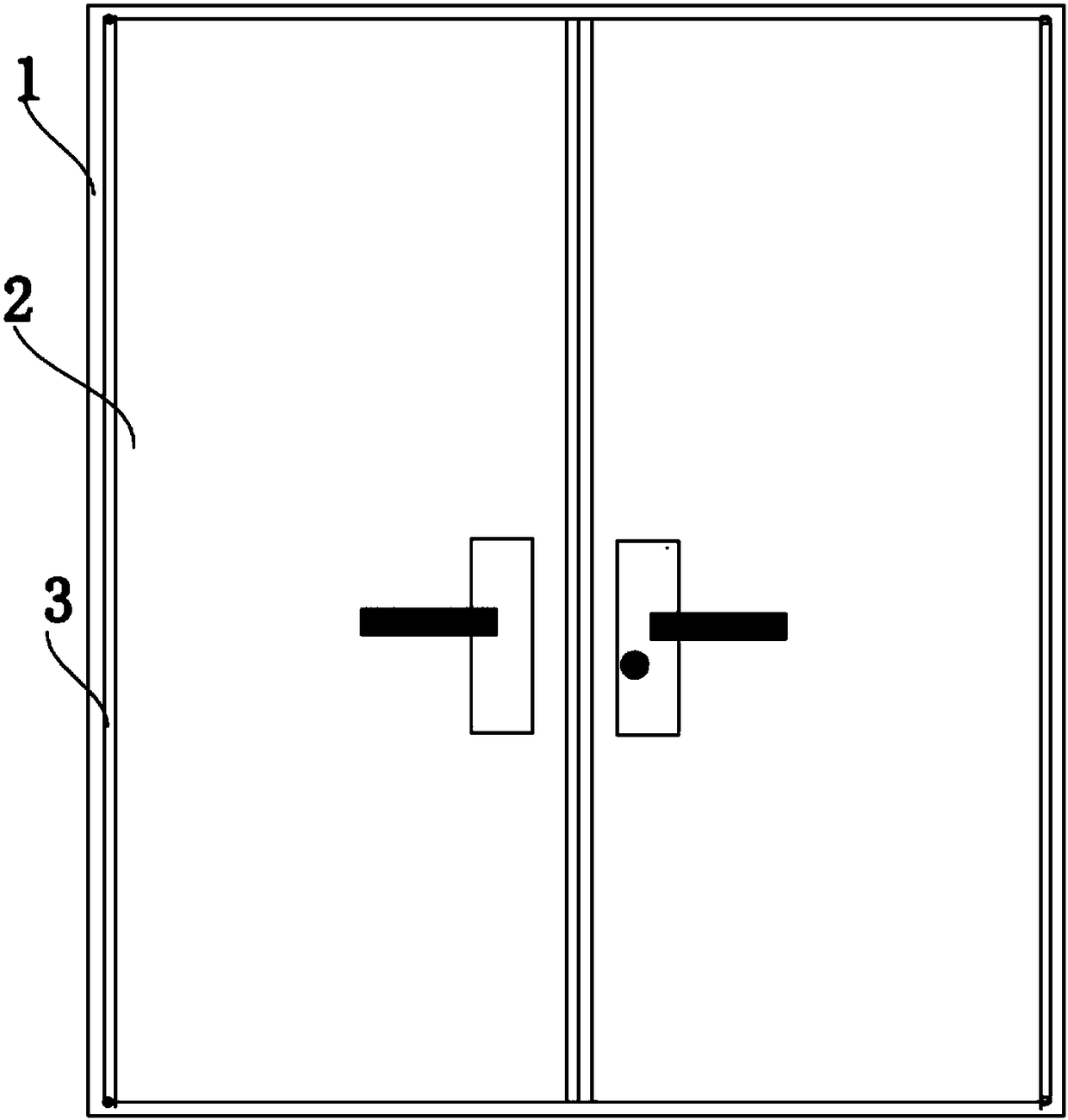

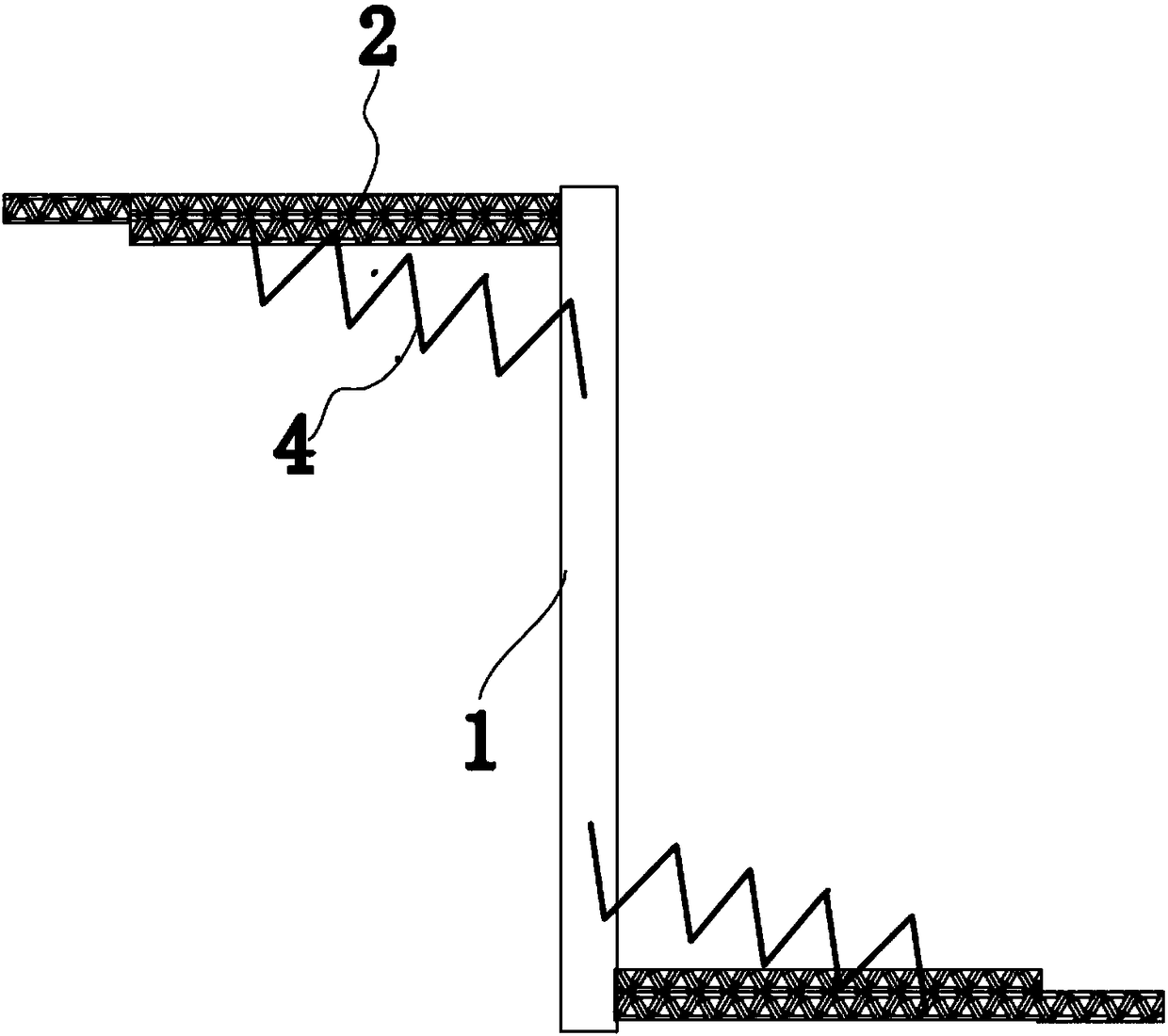

[0026] Please refer to the attached figure 1 , attached figure 2 And attached image 3 , which discloses Embodiment 1 of the present invention, including wherein, 1. Metal door frame, 2. Fire door, 3. Rotating shaft, 4. Extension spring, 5. Fireproof panel, 6. Thermal insulation board.

[0027] An isolation type fire door for a subway tunnel. The outer surface of the metal door frame 1 is inlaid with a flexible graphite sealing strip. The flexible graphite sealing strip rapidly expands to fill the door gap at high temperature, preventing flame spray and smoke from spreading. The fireproof door leaf 2 includes fireproof panels on both sides. 5 and the middle insulation board 6, and the two door leaves are concave-convex fitted with each other. The concave-convex fit makes the two door leaves seamlessly connected, prevents the smoke and flame in the fire from spreading through the gap between the door leaves, and prevents the piston wind from eroding the fire door from the ga...

Embodiment 2

[0029] Please refer to the attached figure 1 And attached figure 2 , which discloses Example 2 of the present invention, this example is similar to Example 1, the difference is that the fireproof housing is made of 60 parts of silicone rubber, 55 parts of silica airgel powder, 30 parts of aluminized polyimide, 20 parts Composed of zinc stannate, 10 parts of chloroplatinic acid, 5 parts of vitrified agent and 7 parts of coupling agent, the thickness of the coating is 1.2cm, the flame retardant liquid is polypropylene nitrile, and the number of heat insulation structures 61 is 30 groups. For expanded perlite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com