Heterogeneous catalyst and method for deep treatment of refractory wastewater

A heterogeneous catalyst and advanced treatment technology, which is applied in molecular sieve catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems of high cost and complicated process, and achieve long life, high reactivity, and pH adaptation broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

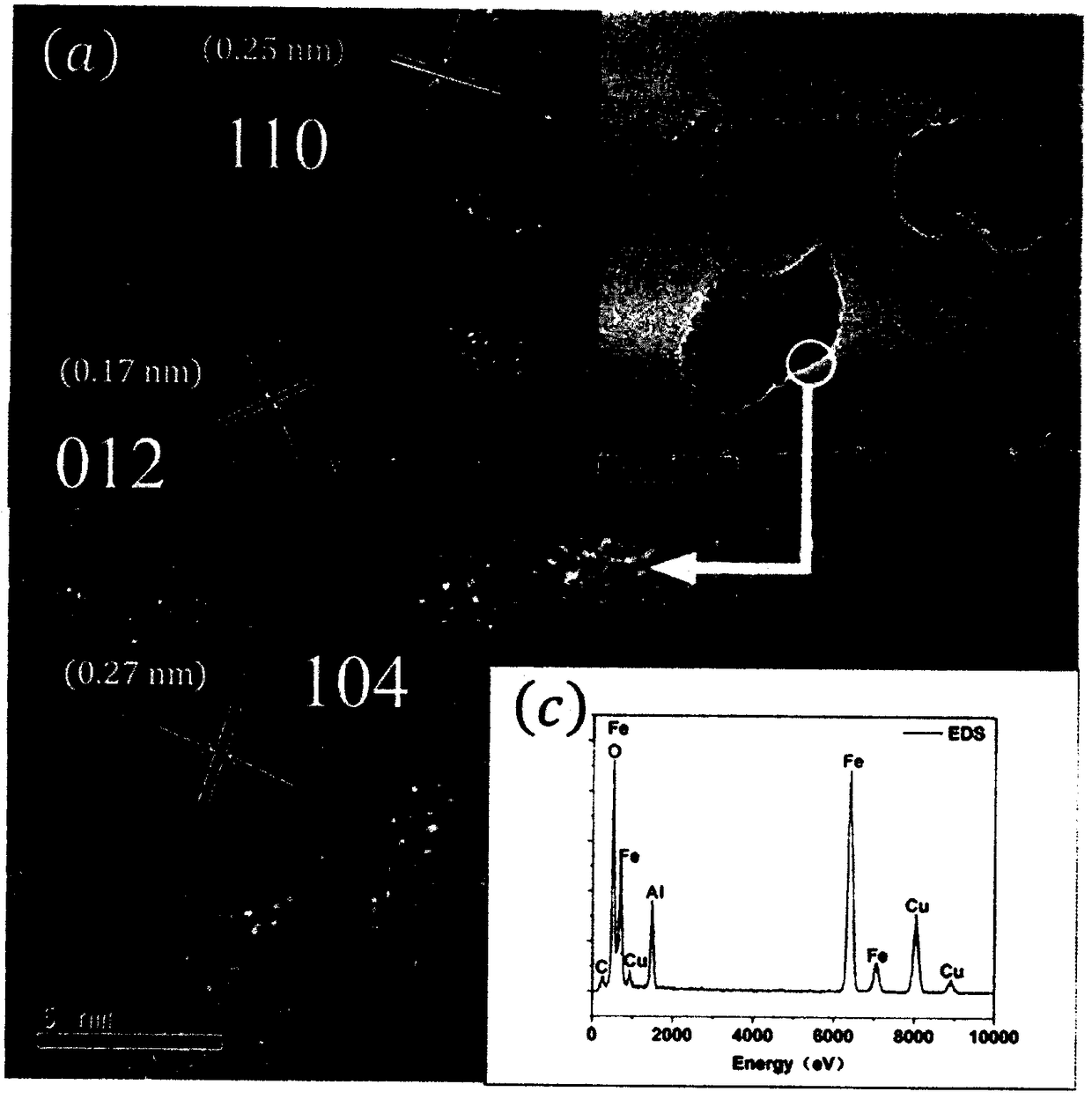

Image

Examples

Embodiment example 1

[0021] Weigh quantitative Al with electronic balance 2 o 3 Carrier and adding an appropriate amount of deionized water for saturated adsorption, determine the Al 2 o 3 Carrier saturated water absorption. Accurately weigh the active component precursor Fe(NO 3 ) 3 9H 2 O and cocatalyst precursor MnSO 4 ·H 2 O is configured into an aqueous solution, and the corresponding mass of the carrier Al will be weighed 2 o 3 Slowly add to the soaking liquid and stir until homogeneous. Immerse it in a water bath at 30°C for 12 hours, then dry it in an oven at 60°C for 12 hours; finally put it in a muffle furnace and bake it at 450°C for 5 hours to obtain a Fe loading of 15% and a cocatalyst loading of 1%. catalyst.

[0022] The initial CODcr of oil production wastewater after biochemical treatment is 198mg / L, pH is 8, catalyst concentration is 2.5g / L, H 2 o 2 The concentration of CODcr was 5.1g / L, and the CODcr was reduced to 42mg / L at a temperature of 70°C for 2h.

Embodiment example 2

[0024] Accurately weigh the active component precursor Fe according to the load 2 (SO 4 ) 3 and cocatalyst precursor Ce(NO 3 ) 4 Configured as an aqueous solution, weigh the corresponding mass of the carrier Al 2 o 3Slowly add to the soaking liquid and stir until homogeneous. Immerse it in a water bath at 30°C for 12h, then dry it in an oven at 60°C for 10h, and finally put it into a muffle furnace and bake it at 650°C for 5h to obtain a Fe loading of 10% and a cocatalyst loading of 0.5%. catalyst.

[0025] The initial pH value of secondary treatment wastewater in paper mills is 8.5, the CODcr is about 400mg / L, and the Cl - The concentration is 200mg / L, SO 4 2- It is 300mg / L, and the absorbance at 400nm is 0.482. When the reaction temperature is 70°C, the amount of catalyst added is 2.5g / L, H 2 o 2 The dosage is 3.0g / L, the reaction time is 90min, the CODcr removal rate reaches 86.2%, and the decolorization rate reaches over 98.6%.

Embodiment example 3

[0027] Accurately weigh the active component precursor FeCl3 and the co-catalyst precursor CuSO according to the load 4 ·5H 2 O is configured as an aqueous solution, and the corresponding mass of carrier commercial activated carbon is slowly added to the impregnation solution and stirred until uniform. Immerse it in a water bath at 30°C for 10h, then dry it in an oven at 60°C for 10h; finally put it into a muffle furnace and bake it at 400°C for 4h.

[0028] 1000mg / L acid scarlet-3R dye wastewater, pH value is 11.8, at reaction temperature 60℃, H 2 o 2 The dosage is 9.4g / L, and the mass concentration of the catalyst is 1.5g / L. The degradation rate of acid scarlet dye wastewater was 99%, and the removal rate of CODcr was 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com