A kind of modified similar material and preparation method thereof

A technology of similar materials and modification, applied in the field of similar materials of geomechanical models and their preparation, can solve the problems of application, inconvenient operation, and infrequent use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

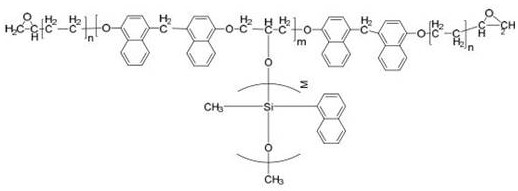

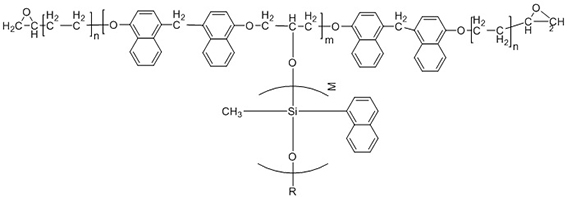

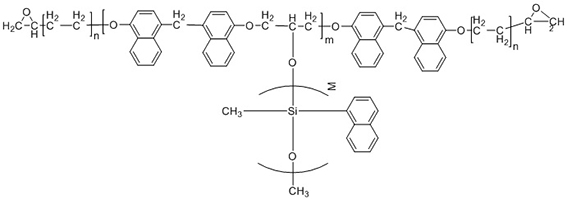

[0039] In the three-necked flask that stirrer is equipped with, add 500g formula Ia compound (AR, purchased from Dow-Corning Company) and 60g formula Ib (AR, purchased from Liaoning Province organosilicon resin factory) compound, inert gas protection, start stirring device And raise the temperature to 110°C. After the two are mixed evenly, add 3g of titanium tetrachloride-triethylaluminum, control the rotation speed at 600r / min, stir and react for 10 hours, stop stirring, and obtain R as a polymer of methyl Object Ic.

[0040]

[0041] Ia

[0042] +

[0043]

[0044] Ib

[0045] ↓

[0046]

[0047] IC

[0048] where M w 1.22×10 4 ,M n 4.52×10 3 , The molecular weight distribution index is 2.6.

Embodiment 2

[0050] First, mix 100 parts of barite powder with a particle size of 200 mesh and 0.015 parts of polymer of formula Ic evenly, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 4 parts of No. 32 hydraulic machine oil to the dried Mix the barite powder and the polymer of formula Ic evenly, and then crush the mixed material until its particle size is ≤1mm; add 1.8 parts of cement marked 525 to the barite powder, the polymer of formula Ic and No. 32 hydraulic machine oil In the mixture, continue to mix evenly; finally add 2 parts of water to the above mixture, and mix evenly. The material has a compressive strength of 0.76 MPa and a modulus of deformation of 12.1 MPa.

Embodiment 3

[0052] First mix 100 parts of barite powder with a particle size of 200 mesh and 0.013 parts of polymer of formula Ic evenly, then dry at 90°C for 3 hours to remove water, take it out and cool to room temperature; add 4 parts of No. 32 hydraulic machine oil to the dried Mix the barite powder and the polymer mixture of formula Ic evenly, and then crush the mixed material to a particle size ≤ 1mm; add 1 part of cement marked 425 to the barite powder, polymer formula Ic and No. 32 hydraulic press In the oil mixture, continue to mix well; finally add 2.5 parts of water to the above mixture, and mix well. The material has a compressive strength of 0.98MPa and a modulus of deformation of 12.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com