Large-scale preparation method of paecilomyces lilacinus

A technology for Paecilomyces lilacinus and Paecilomyces lilacinus, which is applied in the field of large-scale preparation of Paecilomyces lilacinus, can solve the problems of high environmental requirements, complex production conditions, unfavorable production and the like, and achieves easy thermal insulation, Low equipment dependence, beneficial effects on oxygen supply and exhaust emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

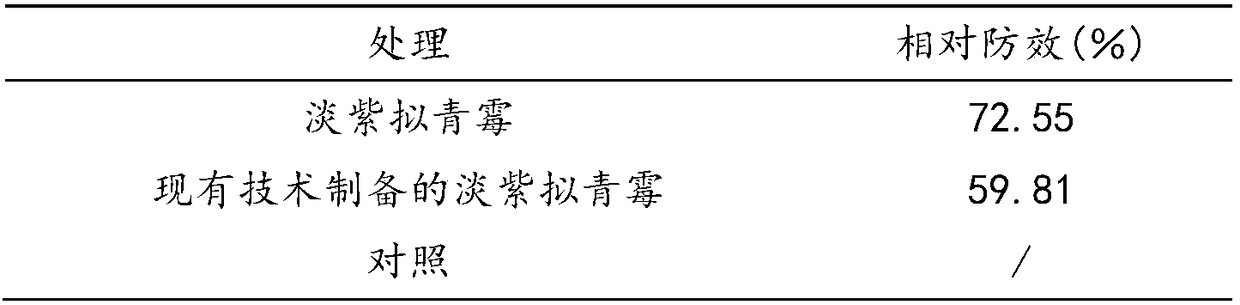

Examples

preparation example Construction

[0027] A large-scale preparation method of Paecilomyces lilacinus, comprising the steps of:

[0028] Inoculating the Paecilomyces lilacinus strain into the sterilized liquid medium for seed culture to obtain liquid seeds;

[0029] Inoculating the liquid seeds into a solid medium with corn cob powder as the main raw material for solid-state fermentation, the solid medium is sterilized, and the inoculum size is 1%-15%, to obtain a fermentation product;

[0030] The fermented product is made into powder by grinding after drying at low temperature.

[0031] What should be explained here is that the solid culture medium using corncob powder as the main raw material has a high fluffiness, which is conducive to the absorption and maintenance of water, thereby greatly reducing the requirements for the humidity of the culture environment. Corn cob meal is derived from agricultural waste and is inexpensive. In addition, turning waste corn cob powder into treasure has great application...

Embodiment 1

[0049] The invention provides a large-scale preparation method of Paecilomyces lilacinus, comprising the following steps:

[0050] The preserved Paecilomyces lilacinus strain is inoculated in a culture bottle equipped with a PDA slant medium, cultivated at 26°C for 9 days to carry out activation culture, and completes strain activation;

[0051] Inoculate into 1L shake flasks with 400mL of liquid medium, culture at 26°C, 150rpm for 7 days, and the inoculum size is 2%; Inoculate the seed liquid in five 1L shake flasks into a 100L seed fermenter with 60L of liquid medium cultured at 26°C and 150rpm for 6 days; the liquid culture medium is made of the following raw materials in percentage by weight: 1% corn flour, 0.01% urea, 3% glucose, 2% ammonium sulfate, and 2% diammonium hydrogen phosphate , 0.01% yeast powder, and the balance is water.

[0052] What should be explained here is: increasing the sulfur content in the liquid medium helps to increase the sulfur content in the s...

Embodiment 2

[0060] The invention provides a large-scale preparation method of Paecilomyces lilacinus, comprising the following steps:

[0061] The preserved Paecilomyces lilacinus strain is inoculated in a culture bottle equipped with a PDA slant medium, cultivated at 28°C for 6 days for activation and cultivation, and completes the activation of the strain;

[0062] Inoculate into 1L shake flasks with 400mL of liquid medium, culture at 28°C and 150rpm for 5 days, and the inoculum size is 5%; Inoculate the seed liquid in five 1L shake flasks into a 100L seed fermenter with 60L of liquid medium cultured at 28°C and 150rpm for 5 days; the liquid medium is made of the following raw materials in percentage by weight: 0.01% corn flour, 0.01% urea, 0.01% glucose, 0.01% ammonium sulfate, and 0.01% diammonium hydrogen phosphate , 3% yeast powder, and the balance is water. What I want to explain here is: increasing the content of yeast powder helps to make the fermentation effect better.

[0063...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com