Recombinant bacillus subtilis and method for promoting synthesis of acetylglucosamine by overexpressing glutamine synthetase by virtue of recombinant bacillus subtilis

A technology of Bacillus subtilis and glutamine, which is applied in the field of genetic engineering, can solve problems such as people who are not suitable for taking seafood allergies, products that easily cause allergic reactions, and environmental pollution, and achieve simple construction methods, improved transformation efficiency, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

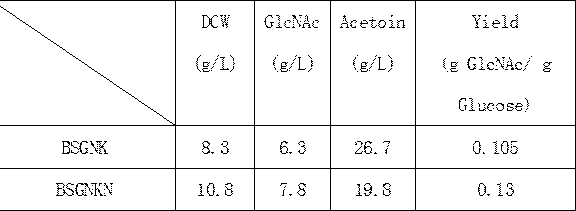

[0024] The recombinant Bacillus subtilis, on the basis of the recombinant Bacillus subtilis BSGNK, further overexpresses the glutamine synthetase (EglnA) from Escherichia coli to obtain the recombinant BSGNKN; the recombinant Bacillus subtilis BSGNK is based on B. subtilis 168 Δ nagP Δ gamP Δ gamA Δ nagA Δ nagB Δ ldh Δ pta Δ glck :: lox72 as the host, respectively with the promoter P xylA ,P 43 control glms, GNA1 recombinant expression. The Escherichia coli glutamine synthetase (EglnA) coding gene glnA As shown in geneID: 948370 in NCBI, geneID: 948370 in NCBI is well known to those of ordinary skill in the art, and will not be described in detail here. The construction integration expression frame of the overexpression source Escherichia coli glutamine synthetase (EglnA) is SEQID NO.1, and is integrated into the glcK site through homologous recombination.

[0025] According to the Bacillus subtilis ( Bacillus subtilis 168 The upstream and downstream sequences of...

Embodiment 2

[0032] In this example, the recombinant bacterium BSGNKN is combined with fermentation medium to produce acetylglucosamine. Specifically, the seed culture solution of the activated recombinant Bacillus subtilis was transferred to the fermentation medium at an inoculation amount of at least 10% for inoculation, and an inducer was added after inoculation for at least 2 h and placed in a 500 mL shake flask within, at 37 o C for at least 48 h at 220 rpm. The inducer includes xylose, and the dosage of xylose is 5 g / L; the filling volume of the shake flask is 50 mL.

[0033] The fermentation medium of the present embodiment comprises the following components in g / L:

[0034] Initial glucose 60, peptone 6, yeast powder 12, (NH 4 ) SO 4 6. K 2 HPO 4 ·3H 2 O 12.5, KH 2 PO 4 2.5, CaCO 3 5. Trace element solution 10 ml / L; said trace element solution includes the following components in g / L: MnSO 4 ·5H 2 O1, Cocl 2 ·6H 2 O 0.4, NaMoO 4 2H 2 O 0.2, ZnSO 4 ·7H 2 O 0.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com