Iron cobalt nickel based anti-DC nanocrystalline alloy material and preparation method thereof

A nanocrystalline alloy, iron-based nanocrystalline technology, applied in magnetic materials, electrical components, circuits, etc., can solve the problems of easy segregation and difficult to control accurately, and achieve high saturation magnetic induction intensity, small phase difference, and small coercivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

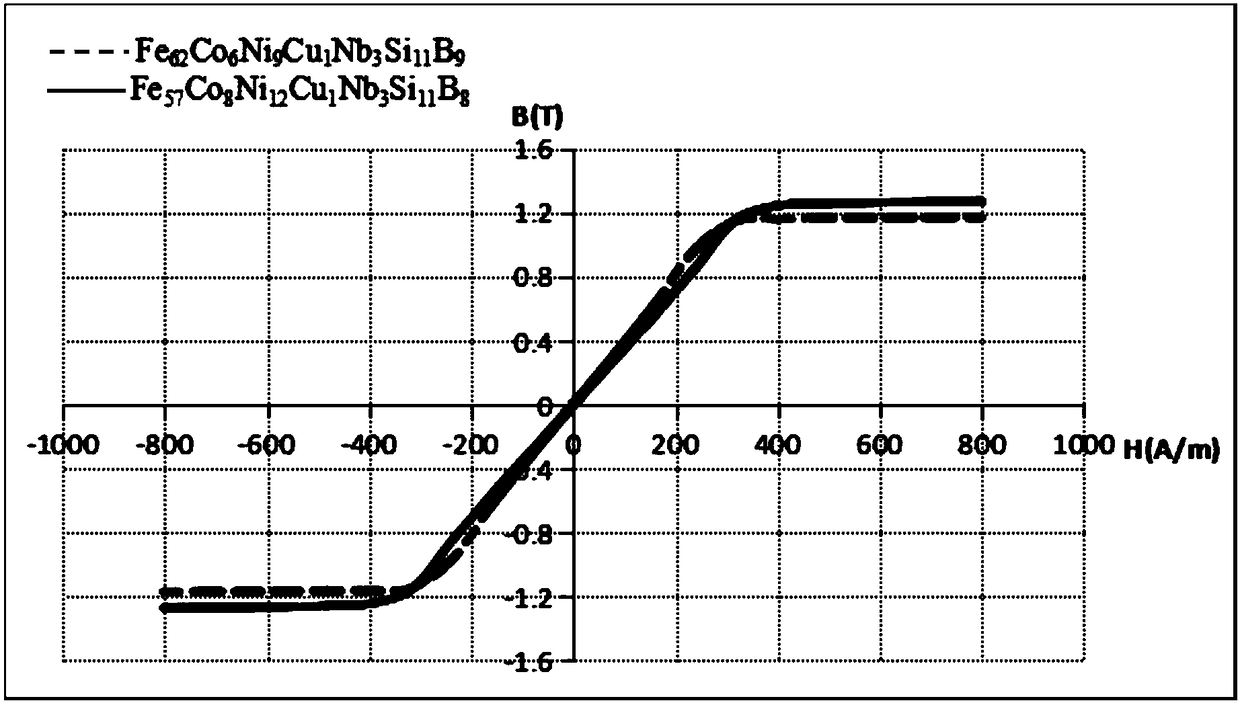

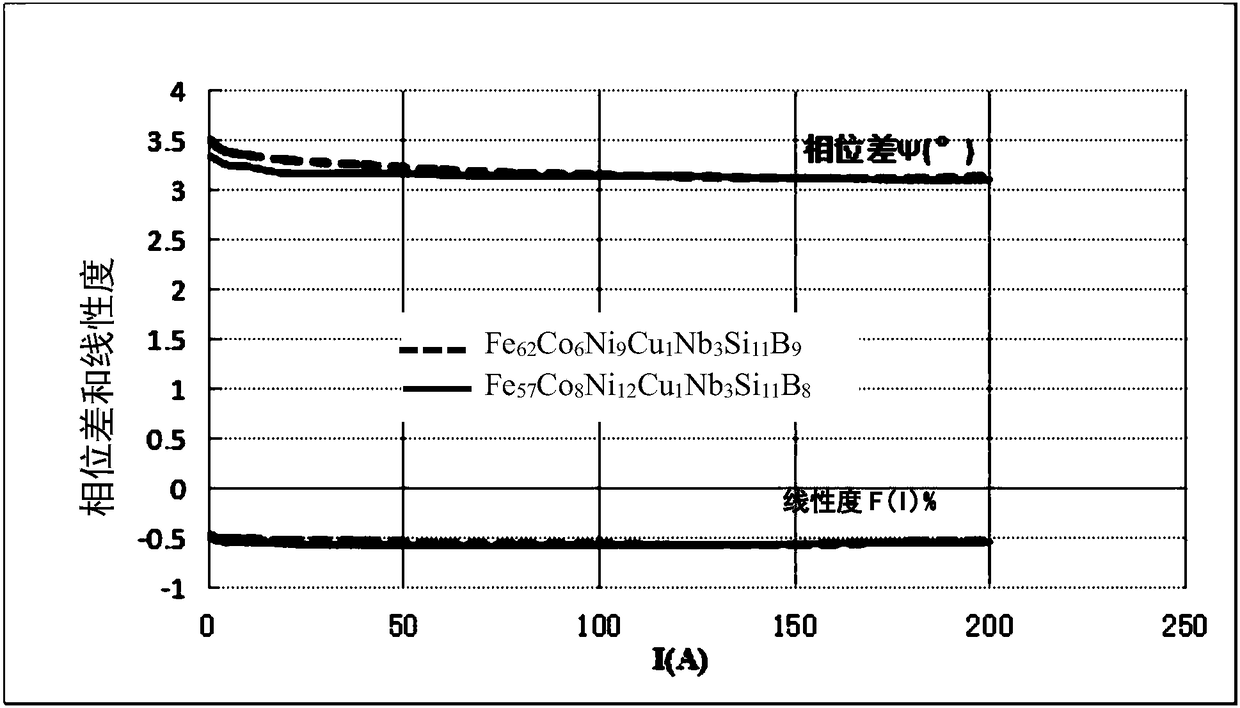

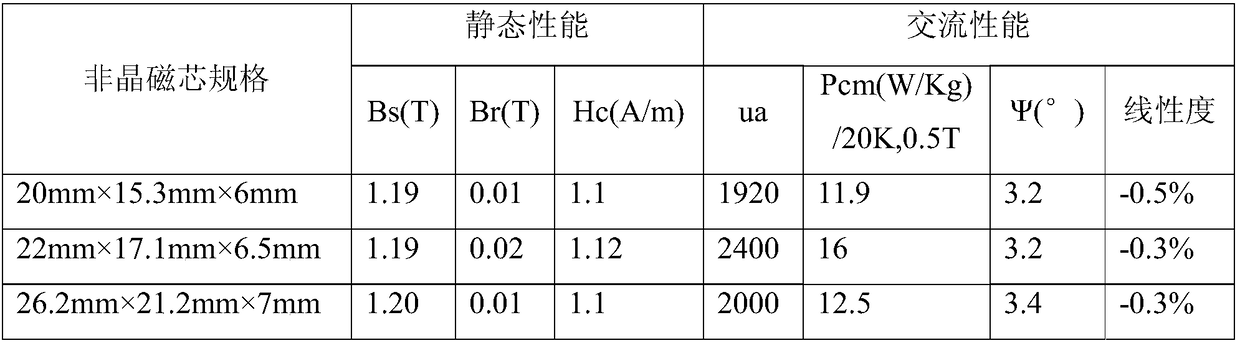

[0031] Select x=6, y=9, z=19 as the atomic ratio of the chemical composition of the master alloy, that is, the composition of the iron-cobalt-nickel anti-DC nanocrystalline alloy material is Fe 62 co 6 Ni 9 Cu 1 Nb 3 Si 11 B 8 . The preparation steps are as follows:

[0032] (1) According to the atomic molecular formula Fe 62 co 6 Ni 9 Cu 1 Nb 3 Si 11 B 8Carry out batching, the raw material of batching is smelted, in the smelting process, add deslagging agent simultaneously; After 1460 and keep warm for 50 minutes, cast into master alloy ingot; Wherein, the raw material usage situation is as follows in the present embodiment: Fe is industrial pure Iron, Si is industrial polysilicon, B is industrial ferroboron, Cu is electrolytic copper; Nb is industrial ferroniobium; Co is industrial cobalt; Ni is industrial nickel block;

[0033] (2) After crushing the master alloy ingot obtained in step (1), put it into the intermediate frequency induction heating melting furna...

Embodiment 2

[0040] Select x=8, y=12, z=20 as the atomic ratio of the chemical composition of the master alloy, that is, the composition of the iron-based low magnetic permeability anti-DC nanocrystalline material is Fe 57 co 8 Ni 12 Cu 1 Nb 3 Si 11 B 8 . The preparation steps are as follows:

[0041] (1) According to the atomic molecular formula Fe 57 co 8 Ni 12 Cu 1 Nb 3 Si 11 B 8 For batching, the raw materials for batching are smelted. During the smelting process, a slag remover is added at the same time; after being kept at 1460°C for 50 minutes, it is cast into a master alloy ingot; wherein, the use of raw materials in this embodiment is as follows: Fe is industrial Pure iron, Si is industrial polysilicon, B is industrial ferroboron, Cu is electrolytic copper; Nb is industrial ferroniobium; Co is industrial cobalt; Ni is industrial nickel block;

[0042] (2) Break the master alloy ingot obtained in step (1) into the intermediate frequency induction heating melting furna...

Embodiment 3

[0049] Select x=4, y=6, z=18.5 as the atomic ratio of the chemical composition of the master alloy, that is, the composition of the iron-based low magnetic permeability anti-DC nanocrystalline material is Fe 67.5 co 4 Ni 6 Cu 1 Nb 3 Si 10 B 8 . The preparation steps are as follows:

[0050] (1) According to the atomic molecular formula Fe 67.5 co 4 Ni 6 Cu 1 Nb 3 Si 10 B 8 For batching, the raw materials for batching are smelted. During the smelting process, a slag remover is added at the same time; after being kept at 1400°C for 100 minutes, it is cast into a master alloy ingot; wherein, the raw material usage in this embodiment is as follows: Fe is industrial Pure iron, Si is industrial polysilicon, B is industrial ferroboron, Cu is electrolytic copper; Nb is industrial ferroniobium; Co is industrial cobalt; Ni is industrial nickel block;

[0051] (2) Break the master alloy ingot obtained in step (1) into the intermediate frequency induction heating melting fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com