pH monitoring flat panel optrode fluorescence sensing film, preparation method and application

A technology of fluorescent sensing film and optode, which is applied in the direction of fluorescence/phosphorescence, testing pH value, chemical instruments and methods, etc., can solve the problems of narrow application range and easy leakage of fluorescent dyes, etc., to reduce the possibility of dye leakage, The effect of strong hydrophobicity and enhanced hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

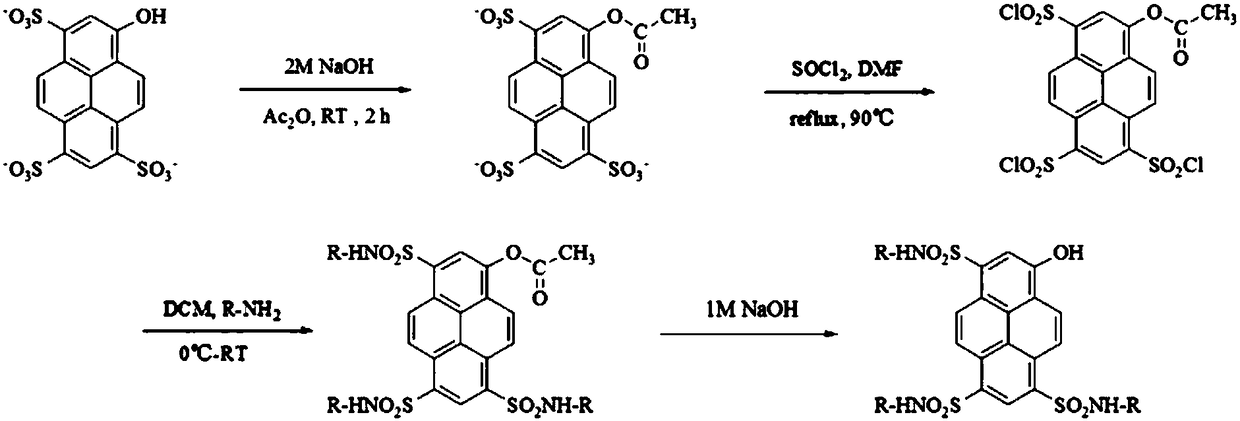

[0053] The preparation process of the fluorescent dye HPTS-lipo of the present embodiment comprises the following steps:

[0054] 1) In 2mol / L NaOH solution, HPTS and acetic anhydride were reacted at room temperature according to 1:3 times equivalent, and the product was extracted with absolute ethanol and suction filtered to obtain the hydroxyl-protected product;

[0055] 2) Hydroxyl-protected HPTS and thionyl chloride were heated to reflux at 90°C for 2 hours according to the ratio of 1:4 times to obtain the sulfonyl chloride intermediate, and the thionyl chloride was spin-dried to obtain HPTS-SO 2 Cl;

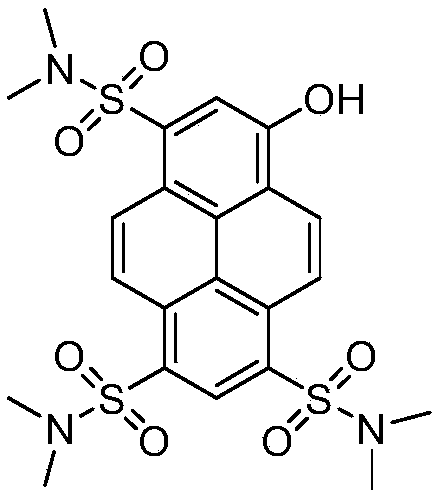

[0056] 3) HPTS-SO 2 Dissolve Cl in dichloromethane, add dropwise dimethylamine at the ratio of 1:3.1 equivalents under ice-bath conditions, spin evaporate and deprotect with 1mol / L NaOH after the reaction, and obtain the final product through column separation to obtain the pure product HPTS -lipo, dimethylamine-HPTS, figure 2 is a schematic diagram of the chemical struc...

Embodiment 2

[0075] The preparation process of the fluorescent dye HPTS-lipo of the present embodiment comprises the following steps:

[0076] 1) In 2mol / L NaOH solution, HPTS and acetic anhydride were reacted at room temperature according to the ratio of 1:3 times, and the product was extracted with absolute ethanol and suction filtered to obtain the hydroxyl-protected product;

[0077] 2) Hydroxyl-protected HPTS and thionyl chloride were heated to reflux at 90°C for 2 hours according to the ratio of 1:4 times to obtain the sulfonyl chloride intermediate, and the thionyl chloride was spin-dried to obtain HPTS-SO 2 Cl.

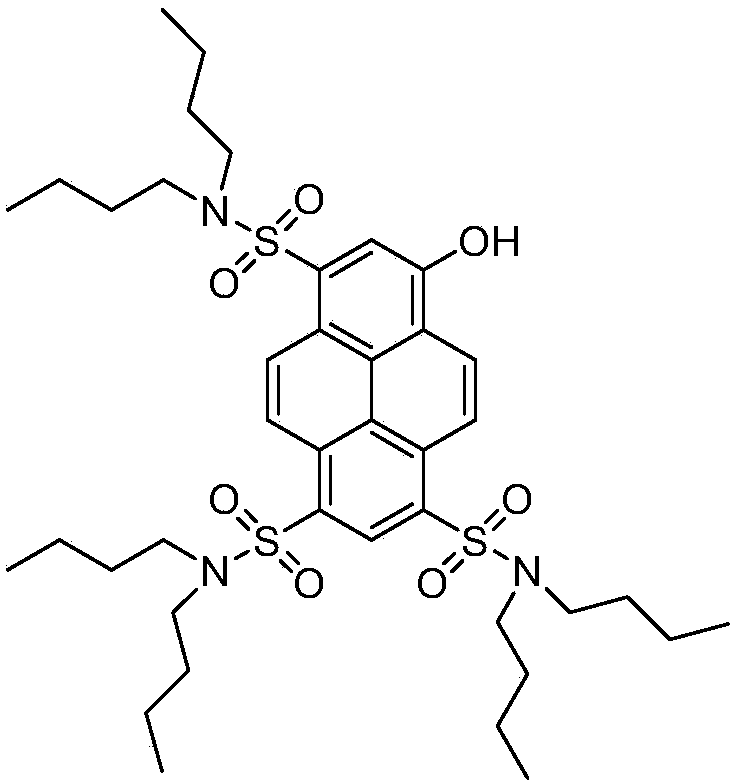

[0078] 3) HPTS-SO 2 Cl was dissolved in dichloromethane, and di-n-butylamine was added dropwise at an equivalent ratio of 1:3.1 under ice bath conditions. After the reaction was completed, it was rotary evaporated and deprotected with 1mol / L NaOH to obtain the final product, which was separated by column separation into pure The product HPTS-lipo, that is, di-n-butylamin...

Embodiment 3

[0090] The preparation process of the fluorescent dye HPTS-lipo of the present embodiment comprises the following steps:

[0091] 1) In 2mol / L NaOH solution, HPTS and acetic anhydride were reacted at room temperature according to the ratio of 1:3 times, and the product was extracted with absolute ethanol and suction filtered to obtain the hydroxyl-protected product;

[0092] 2) Hydroxyl-protected HPTS and thionyl chloride were heated to reflux at 90° C. for 2 hours to obtain a sulfonyl chloride intermediate; DCM was used as a solvent in an ice bath, and di-n-butylamine was added dropwise;

[0093] 3) Step 2) After the reaction is completed, spin dry and deprotect with 1 mol / L NaOH to obtain the final product through column separation to obtain the pure product HPTS-lipo.

[0094] The steps for preparing a two-dimensional pH fluorescent sensing membrane using the above-mentioned fluorescent dye HPTS-lipo are as follows:

[0095] 1) Dissolve 1 g of hydrogel D4 in 10 mL of 90% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com