Overhead power line whole construction process quality control system and method based on mobile terminal

A quality control system and power line technology, applied in location information-based services, transmission systems, electrical components, etc., can solve problems such as difficult accountability for accidents, no real-time data analysis, and inability to monitor the entire construction process. The effect of achieving reliable contact, ensuring authenticity, and error-free information transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

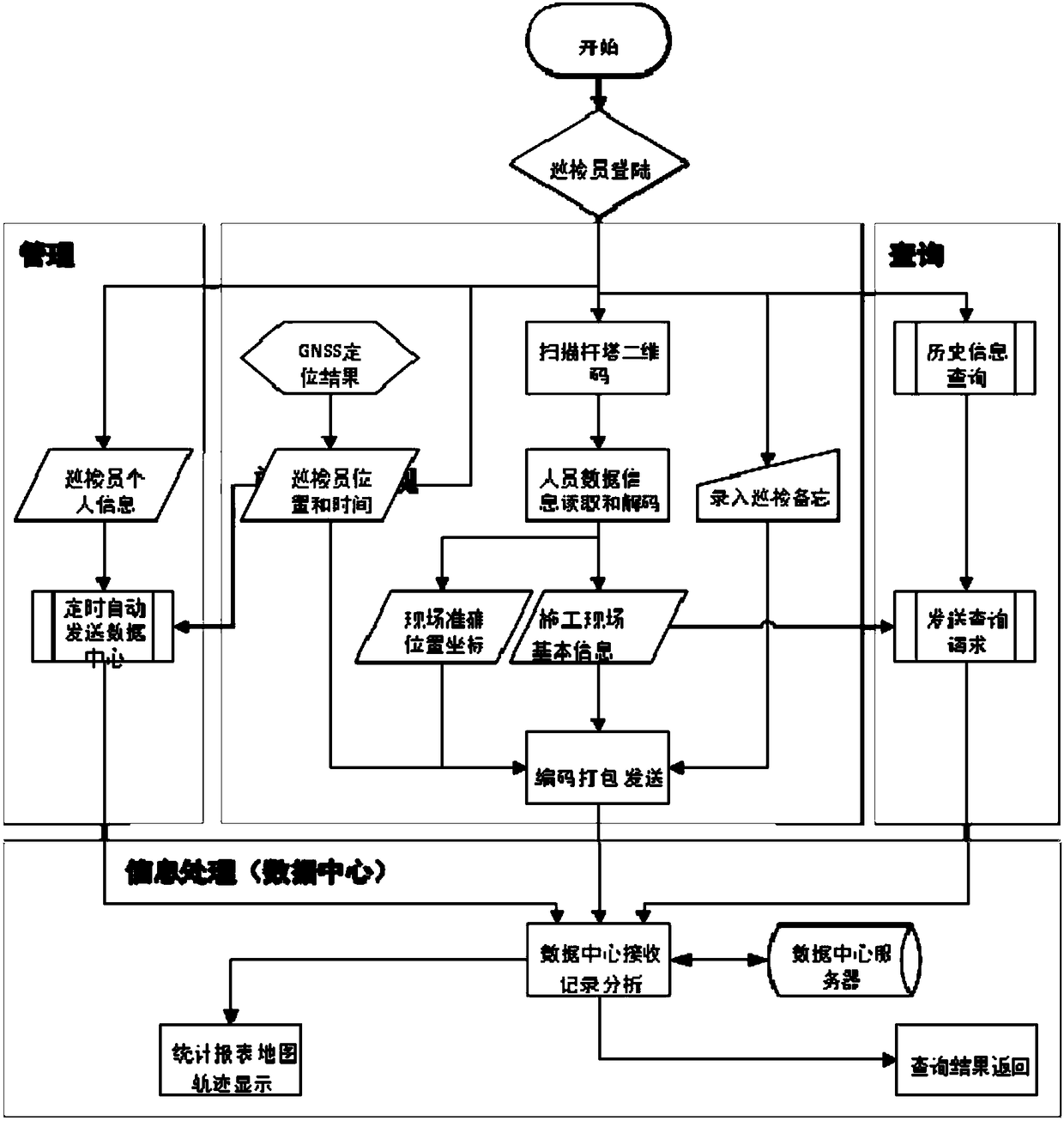

[0073] The present invention will be further described below in conjunction with the accompanying drawings.

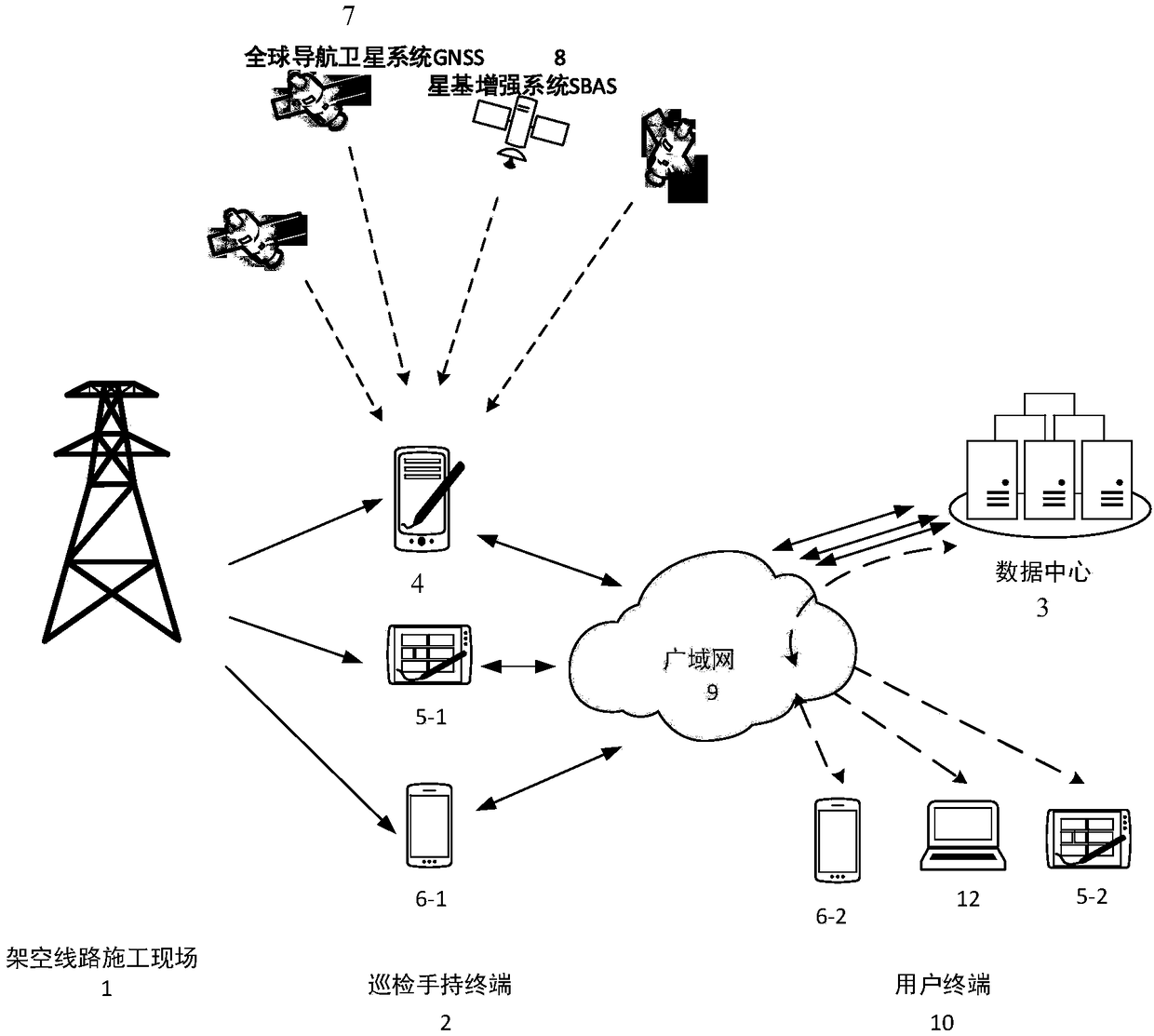

[0074] figure 1 Among them, the technical solution of the present invention provides a quality control system for the whole process of construction of overhead power lines based on mobile terminals. Inspection mobile client and data center, described inspection mobile client is made of hand-held mobile intelligent terminal, and described data center includes background server, and its inventive point is:

[0075] The inspection mobile client has a built-in GNSS receiver module, which can receive GNSS signals for single-point satellite navigation and positioning; when the inspection environment is bad, and buildings or trees around the construction site seriously block the GNSS signals, The GNSS receiver module can perform precise single-point positioning by receiving the satellite differential correction signal of the satellite-based augmentation system SBAS and combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com