Novel rice bread and processing method

A bread and rice technology, applied in the field of food processing, can solve the problems of loose internal structure, easy regeneration and aging, poor taste, etc., and achieve the effects of improving gluten strength, uniform and fine pores, and saving energy and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

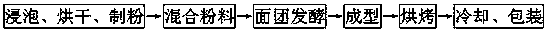

Method used

Image

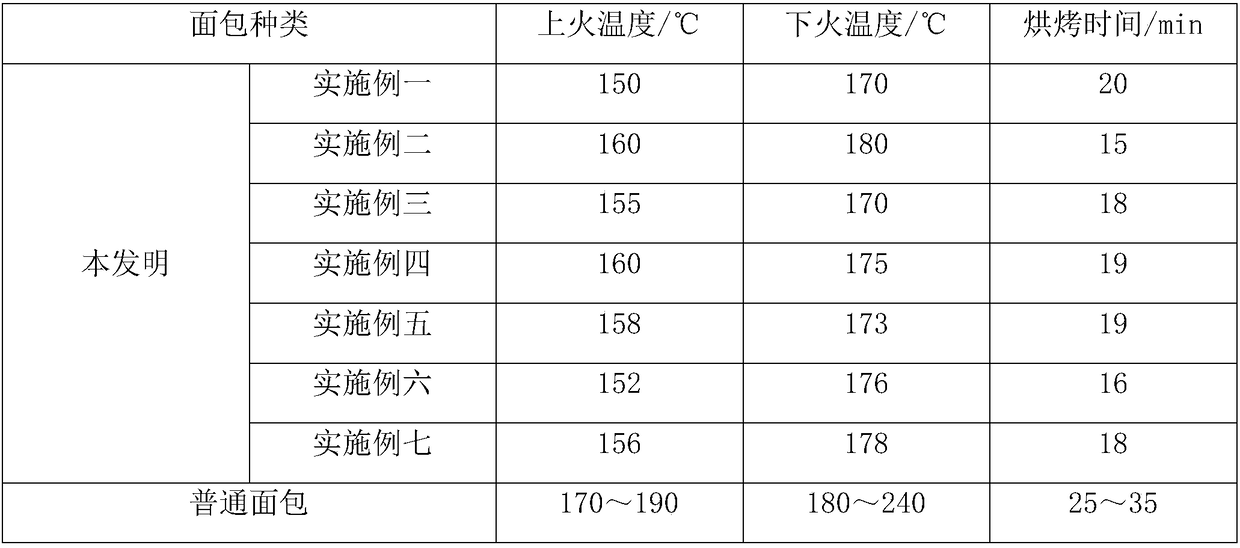

Examples

Embodiment 1

[0028] A novel rice bread, comprising the following components in parts by weight: 60 parts of high-gluten flour, 20 parts of indica rice, 0.8 parts of active dry yeast, 2 parts of stabilizer, 1 part of edible salt, 4 parts of white sugar, 4 parts of butter, 1 part of egg, 0.3 part of bread improver, the stabilizer is composed of xanthan gum and carboxypropyl methylcellulose, the weight ratio of xanthan gum and carboxypropyl methylcellulose is 1:1, the bread The weight ratio of corn starch, soybean protein powder, glucose, vitamin C, calcium sulfate, glucose oxidase, hemicellulase, xylanase, and α-amylase in the improver is 20:10:6:3:2 :0.3:0.2:0.2:0.1.

[0029] The processing method of the novel rice bread of the present embodiment comprises the following steps:

[0030] S1: After cleaning the indica rice, soak it at room temperature for 8 hours, remove it and dry it until the moisture content is 20%, and grind it into 80-mesh rice flour after cooling;

[0031] S2: First mi...

Embodiment 2

[0037] A novel rice bread, comprising the following components in parts by weight: 70 parts of high-gluten flour, 30 parts of indica rice, 1.5 parts of active dry yeast, 4 parts of stabilizer, 3 parts of edible salt, 8 parts of white sugar, 5 parts of butter, 2 parts of eggs, 0.5 part of bread improver, the stabilizer is composed of xanthan gum and carboxypropyl methylcellulose, the weight ratio of xanthan gum and carboxypropyl methylcellulose is 1:1, the bread The weight ratio of corn starch, soybean protein powder, glucose, vitamin C, calcium sulfate, glucose oxidase, hemicellulase, xylanase, and α-amylase in the improver is 20:10:6:3:2 :0.3:0.2:0.2:0.1.

[0038] The processing method of the novel rice bread of the present embodiment comprises the following steps:

[0039] S1: After cleaning the indica rice, soak it at room temperature for 12 hours, remove it and dry it until the water content is 25%, and grind it into 100-mesh rice flour after cooling;

[0040] S2: First ...

Embodiment 3

[0046]A novel rice bread, comprising the following components in parts by weight: 65 parts of high-gluten flour, 25 parts of indica rice, 1 part of active dry yeast, 3 parts of stabilizer, 2 parts of edible salt, 6 parts of white sugar, 4 parts of butter, 1 part of egg, 0.4 part of bread improver, the stabilizer is composed of xanthan gum and carboxypropyl methylcellulose, the weight ratio of xanthan gum and carboxypropyl methylcellulose is 1:1, the bread The weight ratio of corn starch, soybean protein powder, glucose, vitamin C, calcium sulfate, glucose oxidase, hemicellulase, xylanase, and α-amylase in the improver is 20:10:6:3:2 :0.3:0.2:0.2:0.1.

[0047] The processing method of the novel rice bread of the present embodiment comprises the following steps:

[0048] S1: After cleaning the indica rice, soak it at room temperature for 10 hours, remove it and dry it until the water content is 23%, and grind it into 80-mesh rice flour after cooling;

[0049] S2: First mix hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com