Pt@ZrO2 photo-thermal catalyst with hollow core-shell mesoporous structure, and preparation method and application thereof

A core-shell mesoporous and catalyst technology, which is applied in the field of catalytic materials and environmental protection, can solve the problems of limited application, and achieve the effects of convenient operation, promotion of photothermal catalytic reaction, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

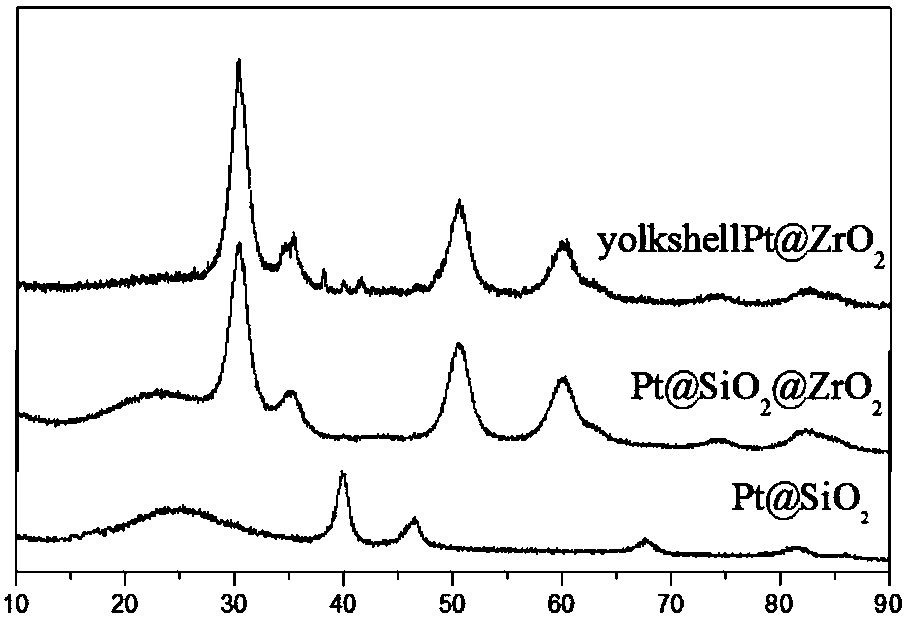

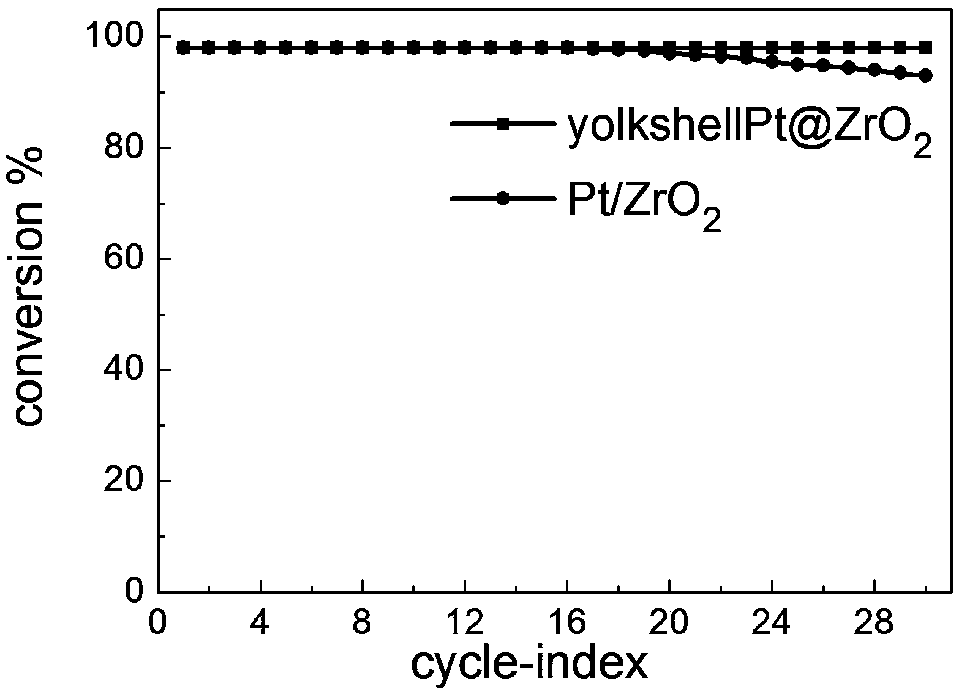

Image

Examples

Embodiment 1

[0023] (1) 10mg H 2 PtCl 6 .6H 2 O, 30ml of deionized water, 60mg of sodium citrate were mixed in a 100ml three-necked flask, stirred and refluxed at 80°C for 4h, and 0.1g of PVP was added after cooling to obtain monodisperse Pt metal nanoparticles; (2) Take 20ml of Pt nanoparticle solution and ultrasonic Disperse in 50ml ethanol solution, slowly add 25wt% ammonia water under rapid stirring to adjust the pH to 10-11, then add 0.5ml tetraethyl orthosilicate, stir at room temperature for 12h, centrifuge, wash with pure water and ethanol three times alternately, and re- Disperse in 100ml of ethanol solution for use; (3) Take 30ml of the solution in step (2), 1ml of deionized water, mix and stir evenly, add 0.5ml of zirconium tetra-n-butoxide, stir for 8h, age for 12h, centrifuge, put Dry at constant temperature in an oven at 60°C for 10 hours to obtain SiO-containing 2 Pt@ZrO 2 powder; (4) ultrasonically disperse the powder in step (3) in NaOH solution and stir at room temper...

Embodiment 2

[0025] (1) 10mg H 2 PtCl 6 .6H 2 O, 30ml of deionized water, 60mg of sodium citrate were mixed in a 100ml three-necked flask, stirred and refluxed at 80°C for 4h, and 0.1g of PVP was added after cooling to obtain monodisperse Pt metal nanoparticles; (2) Take 20ml of Pt nanoparticle solution and ultrasonic Disperse in 50ml ethanol solution, slowly add 25wt% ammonia water under rapid stirring to adjust the pH to 10-11, then add 0.5ml tetraethyl orthosilicate, stir at room temperature for 12h, centrifuge, wash with pure water and ethanol three times alternately, and re- Disperse in 100ml of ethanol solution for use; (3) Measure 30ml of the solution in step (2), 1ml of deionized water, mix and stir evenly, add 0.5ml of zirconium tetra-n-butoxide, stir for 8h, age for 24h, centrifuge, put Put it into a 60°C oven for 10 hours to dry it at a constant temperature to obtain SiO-containing 2 Pt@ZrO 2powder; (4) ultrasonically disperse the powder in step (3) in NaOH solution and stir...

Embodiment 3

[0027] (1) 10mg H 2 PtCl 6 .6H 2 O, 30ml of deionized water, 60mg of sodium citrate were mixed in a 100ml three-neck flask, stirred and refluxed at 80°C for 4h, and 0.2g of PVP was added after cooling to obtain monodisperse Pt metal nanoparticles; (2) Take 20ml of Pt nanoparticle solution and ultrasonic Disperse in 50ml ethanol solution, slowly add 25wt% ammonia water under rapid stirring to adjust the pH to 10-11, then add 0.5ml tetraethyl orthosilicate, stir at room temperature for 12h, centrifuge, wash with pure water and ethanol three times alternately, and re- Disperse in 100ml of ethanol solution for use; (3) Take 30ml of the solution in step (2), 1ml of deionized water, mix and stir evenly, add 0.5ml of zirconium tetra-n-butoxide, stir for 8h, age for 24h, centrifuge, put Dry at constant temperature in an oven at 60°C for 10 hours to obtain SiO-containing 2 Pt@ZrO 2 powder; (4) ultrasonically disperse the powder in step (3) in NaOH solution and stir at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com