Concrete synergist and preparation method thereof

A technology of concrete synergist and polyacrylamide, which is applied in the field of concrete admixtures, can solve the problems that concrete cannot be strengthened, and the degree of hydration cannot reach 100%, so as to improve the overall comprehensive performance, reduce costs, and reduce cement moisture. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

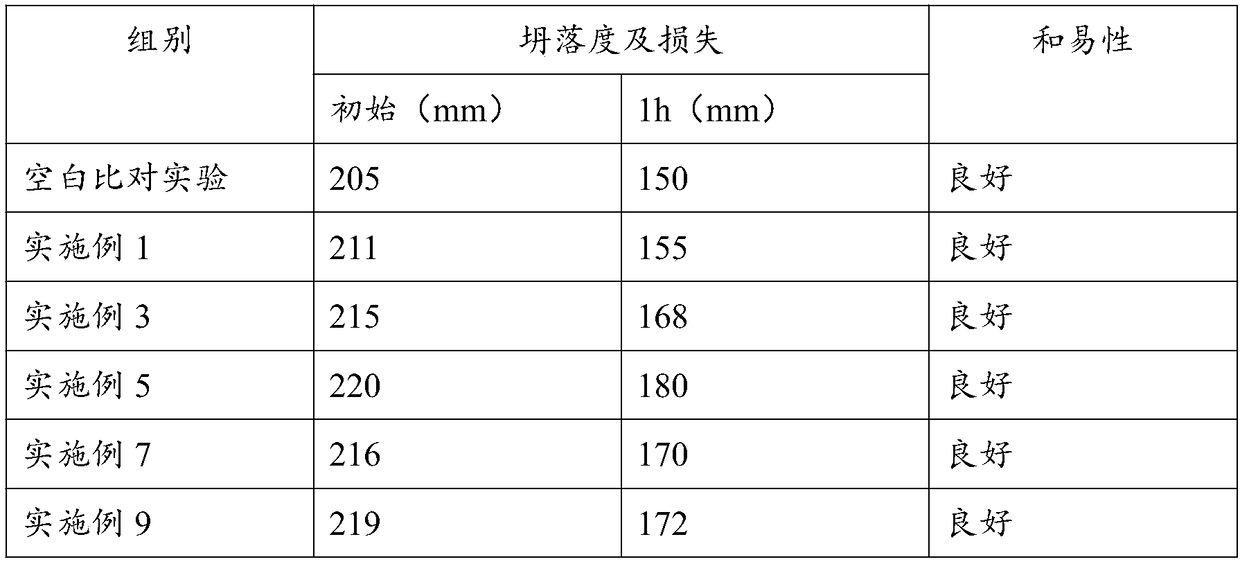

Examples

Embodiment 1

[0049] 1) Weigh each component by weight percentage: polyacrylamide 7KG; sodium sulfite 4KG; polyol 5KG; triisopropanolamine and calcium formate 10KG; sodium diethylenetriaminepentacarboxylate 3KG; sodium hexametaphosphate 2KG; 69KG.

[0050] 2) mixing and stirring the polyol, triisopropanolamine and calcium formate evenly to obtain an initial mixed solution;

[0051] 3) mixing the initial mixed solution with sodium hexametaphosphate, stirring evenly to obtain an intermediate mixed solution;

[0052] 4) Add sodium diethylenetriaminepentacarboxylate, polyacrylamide and sodium sulfite to the intermediate mixed solution, and stir evenly to prepare a high-performance concrete synergist.

Embodiment 2

[0054] 1) Weigh each component by weight percentage: polyacrylamide 12KG; sodium sulfite 18KG; polyol 7KG; triisopropanolamine and calcium formate 15KG; sodium diethylenetriaminepentacarboxylate 5KG; sodium hexametaphosphate 4KG; 39KG.

[0055] 2) mixing and stirring the polyol, triisopropanolamine and calcium formate evenly to obtain an initial mixed solution;

[0056] 3) mixing the initial mixed solution with sodium hexametaphosphate, stirring evenly to obtain an intermediate mixed solution;

[0057] 4) Add sodium diethylenetriaminepentacarboxylate, polyacrylamide and sodium sulfite to the intermediate mixed solution, and stir evenly to prepare a high-performance concrete synergist.

[0058] Example: 3:

[0059] 1) Weigh each component by weight percentage: polyacrylamide 9KG; sodium sulfite 8KG; ethylene glycol 2KG, diethanol triisopropanol 3KG; triisopropanolamine 6KG; calcium formate 4KG; Sodium 3KG; sodium hexametaphosphate 2KG; water 63KG.

[0060] 2) mixing and sti...

Embodiment 4

[0064] 1) Weigh each component by weight percentage: polyacrylamide 10KG; sodium sulfite 12KG; ethylene glycol 3KG, diethanol triisopropanol 4KG; triisopropanolamine 9KG; calcium formate 6KG; Sodium 5KG; sodium hexametaphosphate 4KG; water 47KG.

[0065] 2) mixing and stirring the polyol, triisopropanolamine and calcium formate evenly to obtain an initial mixed solution;

[0066] 3) mixing the initial mixed solution with sodium hexametaphosphate, stirring evenly to obtain an intermediate mixed solution;

[0067] 4) Add sodium diethylenetriaminepentacarboxylate, polyacrylamide and sodium sulfite to the intermediate mixed solution, and stir evenly to prepare a high-performance concrete synergist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com