Self-restoration concrete with enhanced restoration property and preparation method thereof

A concrete and self-healing technology, applied in the field of building materials, can solve problems such as easy cracking of concrete structures, and achieve the effects of saving human and financial resources, controlling the development of cracks, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

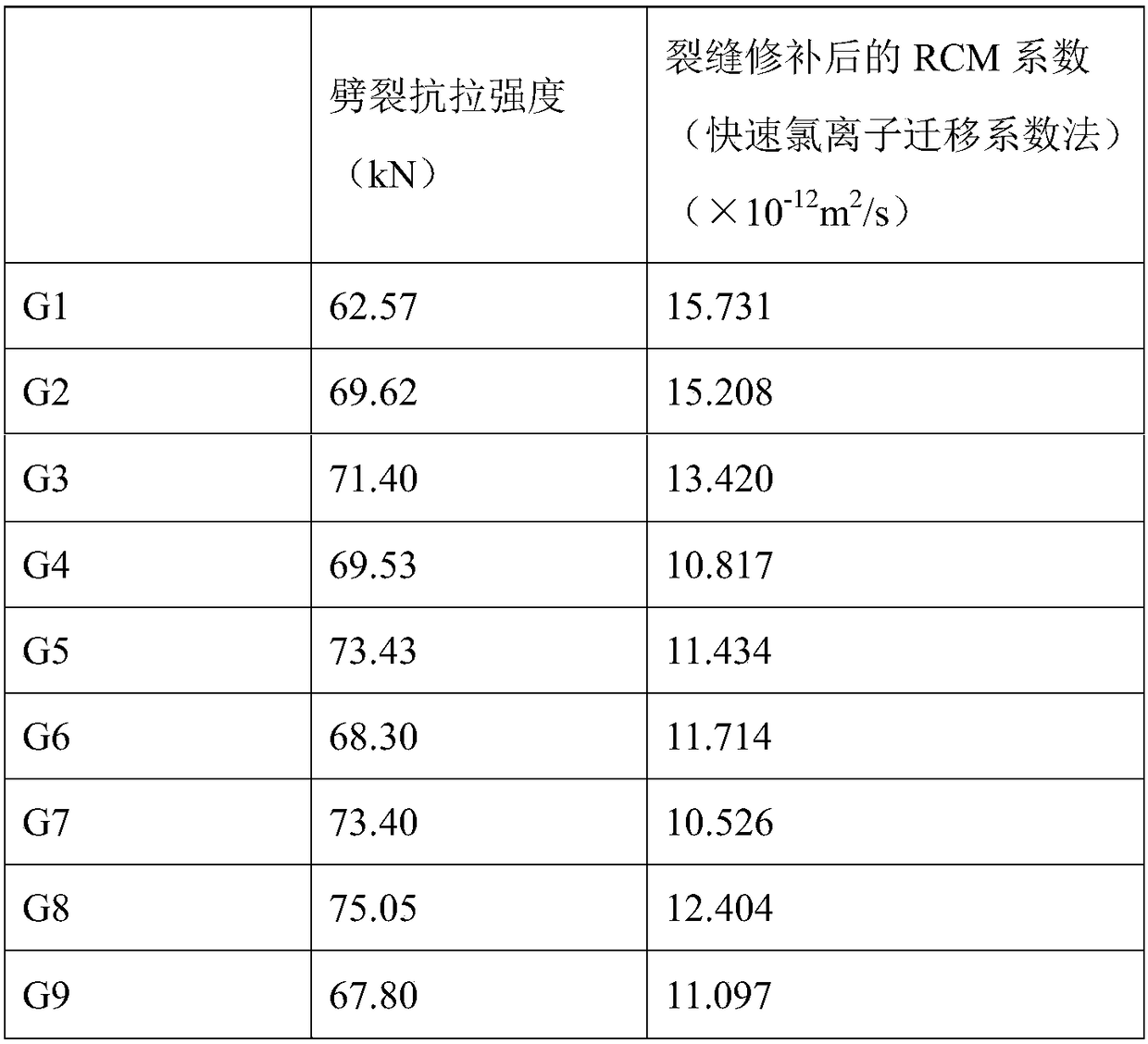

Embodiment 1

[0045] A self-repairing concrete with enhanced repairing performance. The raw materials include the following components in parts by weight: 176 parts of cement, 44 parts of fly ash, 322 parts of fine aggregate, 409 parts of coarse aggregate, 47.3 parts of water, and 0.585 parts of fiber , 3.325 parts of water reducer, 22.5 parts of expansion agent, 4.8 parts of repair material, and 9.3 parts of water storage material.

[0046] The cement is PO42.5 grade cement. The fly ash is Class I fly ash. The fine aggregate is continuously graded medium sand. The coarse aggregate is continuously graded gravel with a particle size of 5mm-15mm. The fibers are cellulose fibers with a length of 2-3mm, an elastic modulus of 8-10Gpa and a tensile strength of 800-900MPa. The water reducer is a polycarboxylate water reducer mother liquor with a solid content of 40 wt%. The expansion agent is calcium sulfoaluminate-calcium oxide composite expansion agent. The repair material is wrapped by a h...

Embodiment 2

[0059] A self-repairing concrete with enhanced repairing performance. The raw materials include the following components in parts by weight: 180 parts of cement, 46.5 parts of fly ash, 335.5 parts of fine aggregate, 426.5 parts of coarse aggregate, 48.4 parts of water, and 0.878 parts of fiber , 3.403 parts of water reducer, 24.75 parts of expansion agent, 4.8 parts of repair material, and 11.63 parts of water storage material.

[0060] The cement is PO42.5 grade cement. The fly ash is Class I fly ash. The fine aggregate is continuously graded medium sand. The coarse aggregate is continuously graded gravel with a particle size of 5mm-15mm. The fibers are cellulose fibers with a length of 2-3mm, an elastic modulus of 8-10Gpa and a tensile strength of 800-900MPa. The water reducer is a polycarboxylate water reducer mother liquor with a solid content of 40 wt%. The expansion agent is calcium sulfoaluminate-calcium oxide composite expansion agent. The repair material is wrapp...

Embodiment 3

[0073] A kind of self-healing concrete with enhanced repair performance. The raw materials include the following components in parts by weight: 190 parts of cement, 49 parts of fly ash, 349 parts of fine aggregate, 444 parts of coarse aggregate, 49.5 parts of water, and 1.17 parts of fiber , 3.48 parts of water reducing agent, 27 parts of expansion agent, 4.8 parts of repair material, and 13.95 parts of water storage material.

[0074] The cement is PO42.5 grade cement. The fly ash is Class I fly ash. The fine aggregate is continuously graded medium sand. The coarse aggregate is continuously graded gravel with a particle size of 5mm-15mm. The fibers are cellulose fibers with a length of 2-3mm, an elastic modulus of 8-10Gpa and a tensile strength of 800-900MPa. The water reducer is a polycarboxylate water reducer mother liquor with a solid content of 40 wt%. The expansion agent is calcium sulfoaluminate-calcium oxide composite expansion agent. The repair material is wrappe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com