Formula and production technology of saggar for firing cathode material for lithium battery

A positive electrode material, lithium battery technology, applied in the field of refractory materials, can solve the problems of high price, mixing, impossible to use in large quantities, etc., to achieve the effect of reducing production costs and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

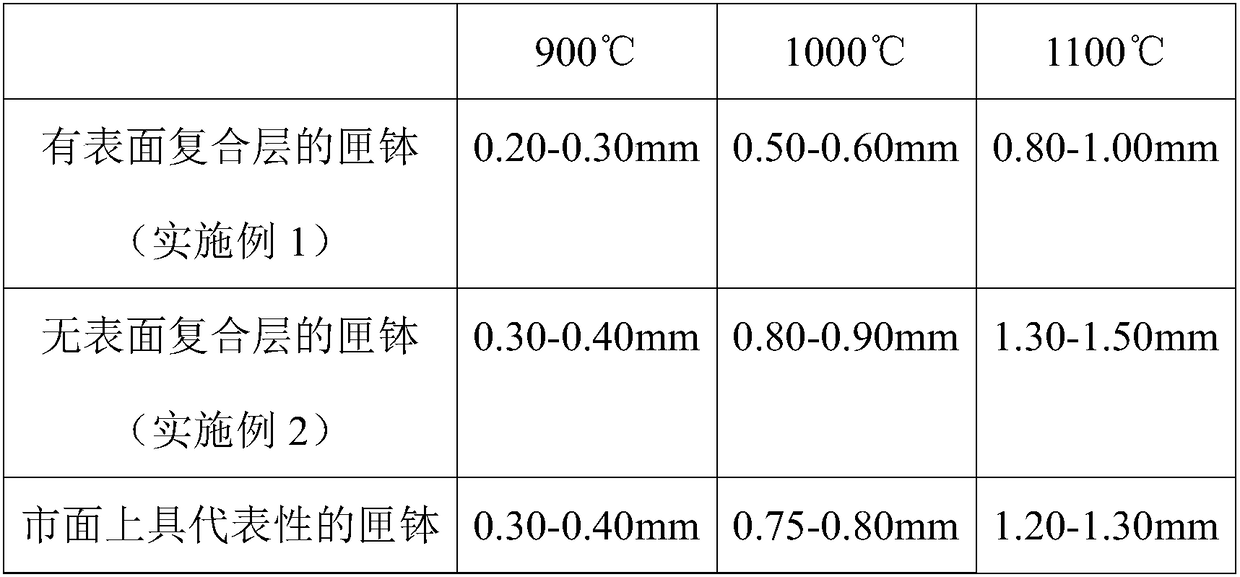

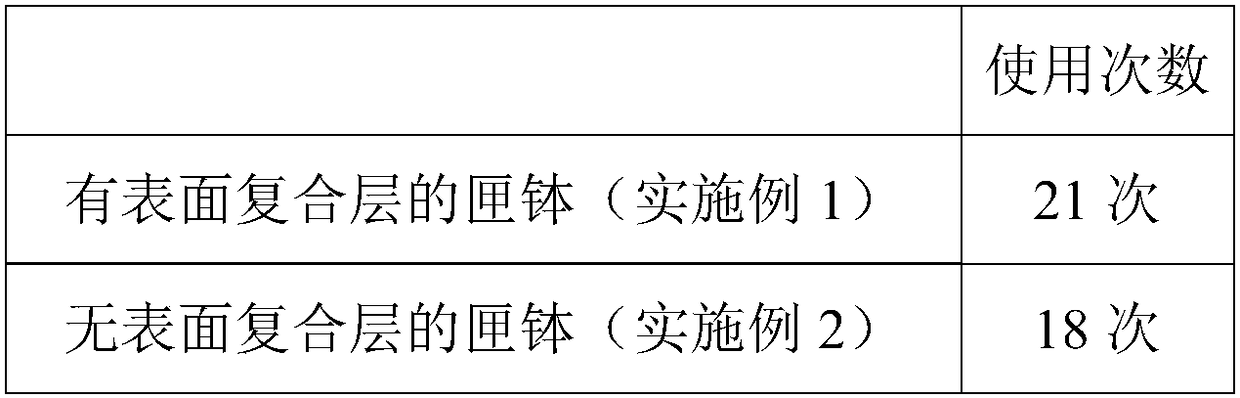

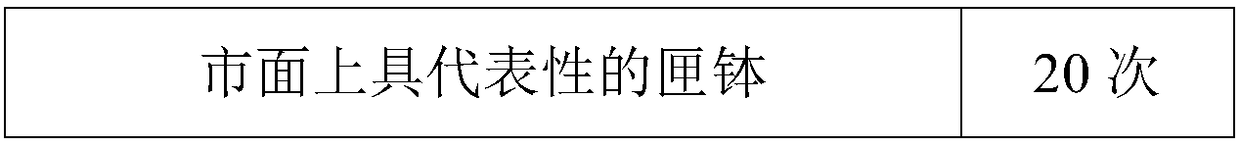

Examples

Embodiment 1

[0037] Embodiment 1: make the saggar with surface composite layer

[0038] 1. Prepare raw materials

[0039] Prepare the raw material for making the surface composite layer according to the surface composite layer formula given before, denote as raw material A, then add a small amount of water in raw material A (the amount of water is specifically 5% of the weight of raw material A), Then put it into the mixing wheel grinding mill for stirring, the stirring time is set to 35min, and finally take it out through a 20-mesh sieve for later use.

[0040] According to the previously given sagger main body formula, the raw materials used to make the sagger main body are obtained, which are recorded as raw material B, and then a small amount of water is added to the raw material B (the amount of water is specifically 5% of the weight of the raw material B), Then put it into the mixing wheel grinding mill for stirring, the stirring time is set to 35min, and finally take it out through...

Embodiment 2

[0047] Embodiment 2: make the sagger without surface composite layer

[0048] 1. Prepare raw materials

[0049] According to the previously given sagger main body formula, the raw materials used to make the sagger main body are obtained, which are recorded as raw material B, and then a small amount of water is added to the raw material B (the amount of water is specifically 5% of the weight of the raw material B), Then put it into the mixing wheel grinding mill for stirring, the stirring time is set to 35min, and finally take it out through a 20-mesh sieve for later use.

[0050] 2. Forming

[0051] Spread 5.6kg of raw material B on the surface of the molding die, press it into a sagger of 320cm x 230cm x 125cm in a 300-ton pressure press with a speed of 350rpm, and let it stand.

[0052] 3. Dry

[0053] After demoulding, the pressed saggar was left to stand in a dry and ventilated room for 24 hours to dry it.

[0054] 4. Firing

[0055] Place the dried sagger in a roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com