Production method of 1,3-butanediol

A production method, the technology of butanediol, which is applied in the production process field of synthesizing 1,3-butanediol, can solve problems such as difficulty in meeting market demand and difficulty in expanding production capacity, and achieve the effect of reducing the production of three wastes and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

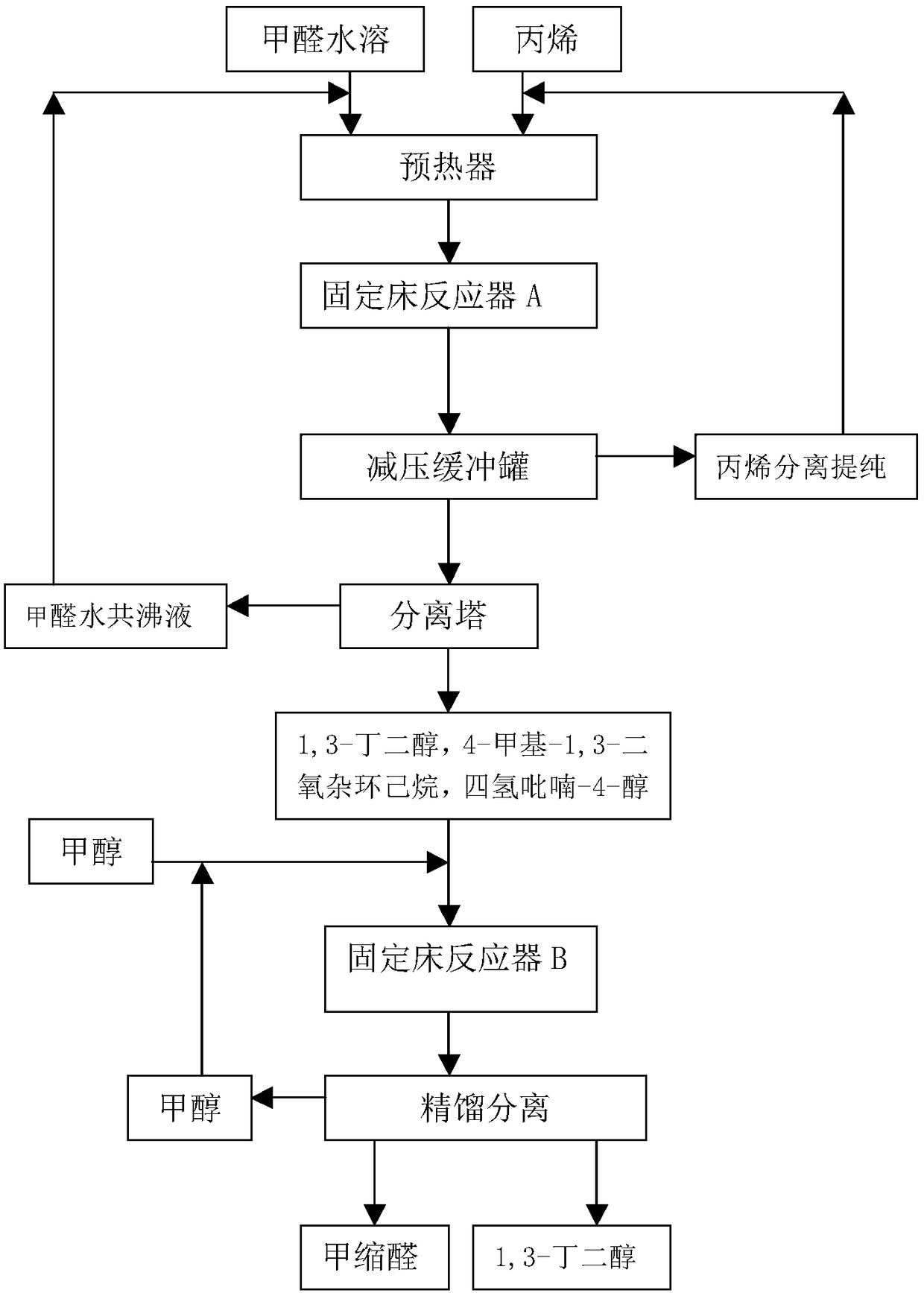

[0033] according to figure 1 Described technical process, use metering pump to pump into 40% formaldehyde aqueous solution and propylene in the single tube stainless steel reactor that acid cationic resin catalyst is housed, control under certain temperature and pressure to react, reaction product chromatographic analysis, reaction condition and The results are shown in Table 1

[0034]

Embodiment 2

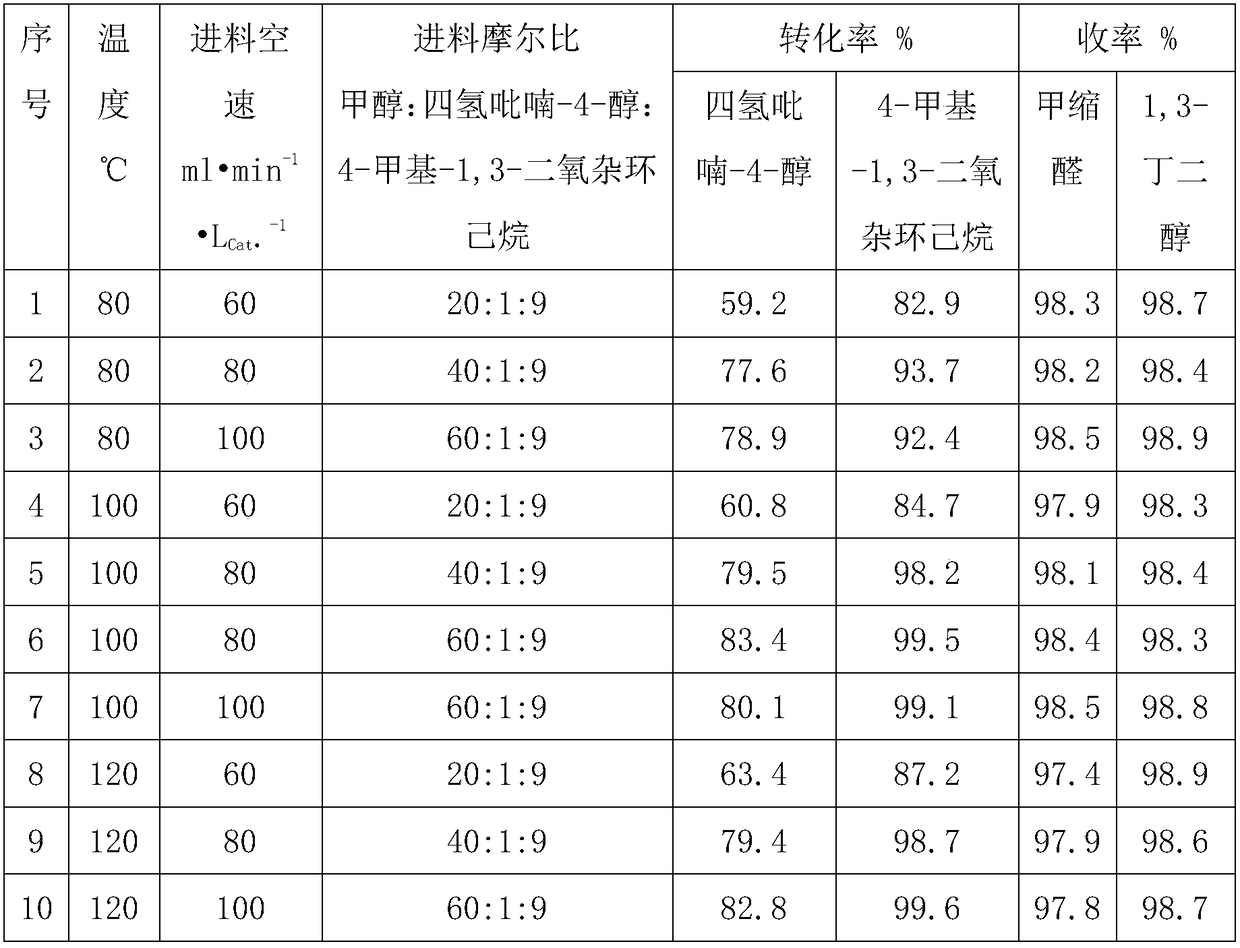

[0036] According to the process flow, a metering pump is used to pump methanol, 4-methyl-1,3-dioxane and tetrahydropyran-4- The mixture of alcohols is controlled to react at a certain temperature and pressure, and the reaction product chromatographic analysis, reaction conditions and results are shown in Table 2

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com