Method of dehydrating 2-methylpyridine by coupling extraction and rectification operations

A picoline and extraction technology, applied in the separation field of 2-picoline dehydration, can solve the problem of high moisture content, achieve the effects of low energy consumption, wide application range and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the application example of dehydration method of the present invention in batch rectification mode of operation

[0020] Take by weighing 100g 2-picoline respectively, 150g water, 600g carbon tetrachloride, now extractant consumption is 6 times of 2-picoline quality, material is placed in separating funnel, it is sealed with glass stopper, Shake the separatory funnel to mix the materials evenly, then let it stand for 2h, and you can see obvious stratification, wherein the upper layer is an aqueous phase, and the lower layer is an organic phase containing 2-picoline and carbon tetrachloride; The phase mass is 149.5g, and the mass fractions of water, 2-picoline, and carbon tetrachloride are 99.2%, 0.74%, and 0.06%, respectively.

[0021] Release the organic phase from the valve below the separatory funnel, feed it to the bottom of the batch distillation tower containing 30 trays at one time, turn on the condensate water, turn on the heating device of the bot...

Embodiment 2

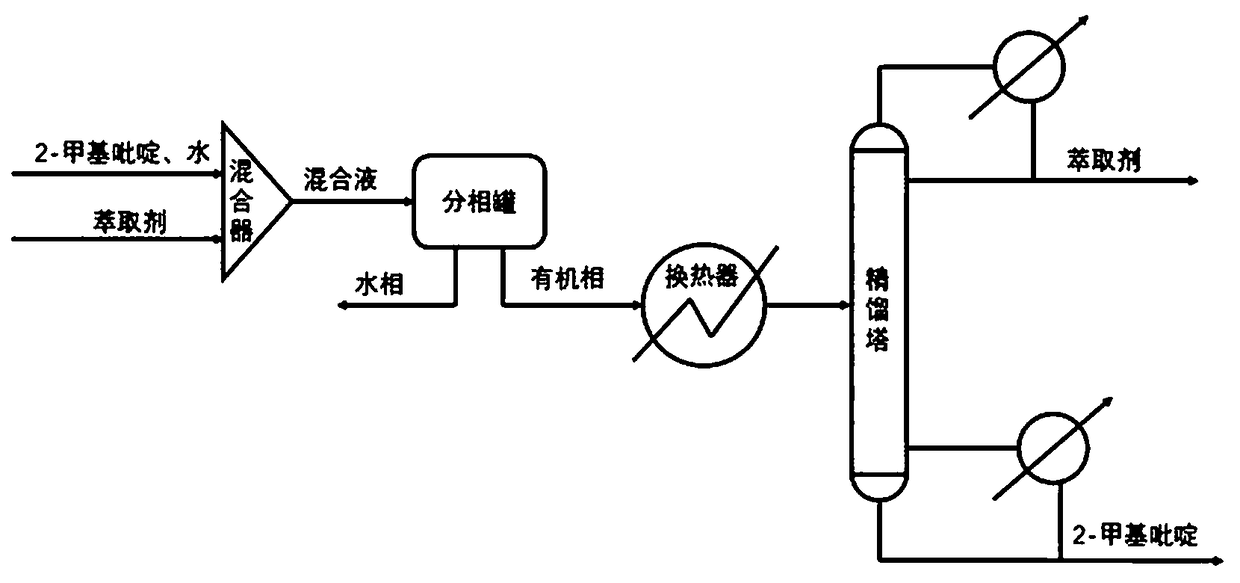

[0024] The application example of the dehydration method of the present invention in the continuous rectification operation mode.

[0025] 2-picoline / aqueous solution and extraction agent are all continuous feeding, and wherein in 2-picoline / aqueous solution, the mass fraction of 2-picoline is 50%, feed flow rate is 200kg / h, extraction agent four The feed flow rate of carbon chloride is 800kg / h. At this time, the amount of extractant is 8 times the mass of 2-picoline. After the two are mixed evenly by the mixer, they enter the phase separation tank for phase separation to ensure that the materials are phase separated. The time can reach 1h, and the aqueous phase and organic phase can be continuously extracted. The produced water phase flow rate is 99.8kg / h, and the organic phase flow rate is 900.2 kg / h.

[0026] The organic phase extracted from the phase separation tank is preheated to 60°C through a heat exchanger, and is continuously fed to the rectification tower with 40 t...

Embodiment 3

[0029] When the dehydration method of the present invention is low in feed concentration, the application example in the continuous rectification mode of operation:

[0030] 2-picoline / aqueous solution and extraction agent are all continuous feeding, and wherein in 2-picoline / aqueous solution, the mass fraction of 2-picoline is 10%, feed flow rate is 200kg / h, extraction agent four The feed flow rate of chlorinated carbon is 200kg / h. At this time, the amount of extractant is 10 times the mass of 2-picoline. After the two are mixed evenly by the mixer, they enter the phase separation tank for phase separation to ensure that the materials are phase separated. The time can reach 5h, and the aqueous phase and organic phase can be continuously extracted. The flow rate of the aqueous phase is 181.2 kg / h, and the flow rate of the organic phase is 218.8 kg / h.

[0031] The organic phase extracted from the phase separation tank is preheated to 50°C through a heat exchanger, and is conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com