High-performance polyamide composite separation membrane based on biopolymer fouling base membrane and preparation method thereof

A polyamide and separation membrane technology, applied in the field of membrane separation, to achieve the effects of enhanced water permeability, simple operation and guaranteed retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

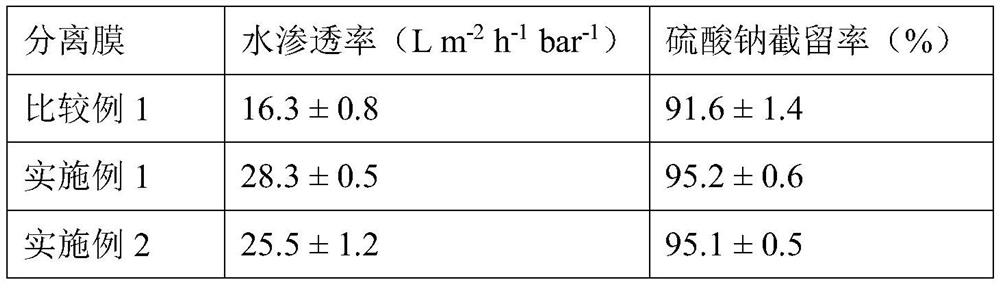

Embodiment 1

[0027] Preparation of High Performance Polyamide Composite Separation Membrane Based on Polysaccharide Contaminated Base Membrane:

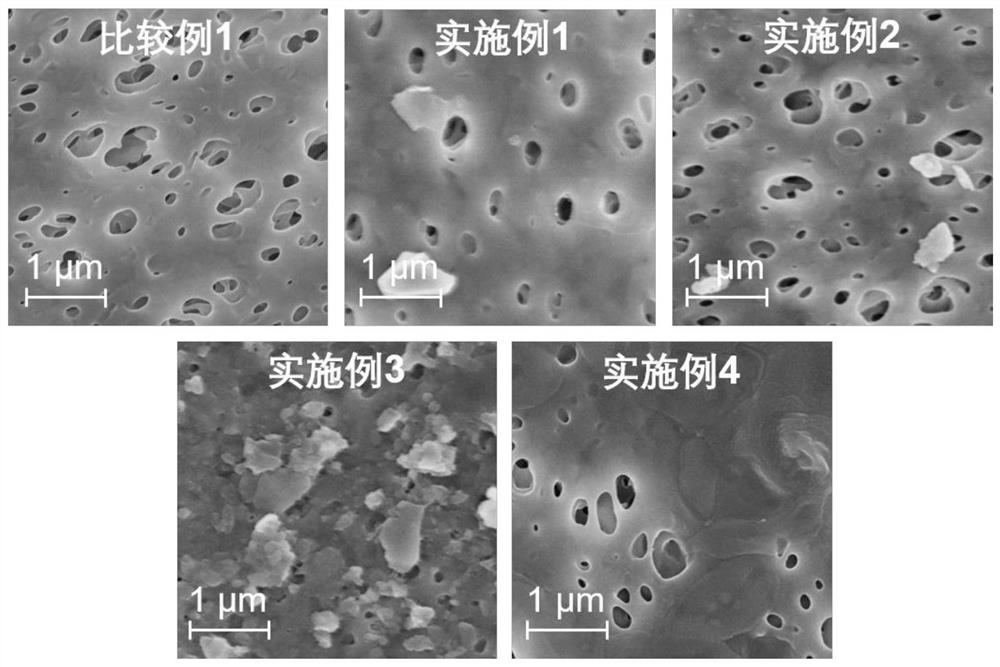

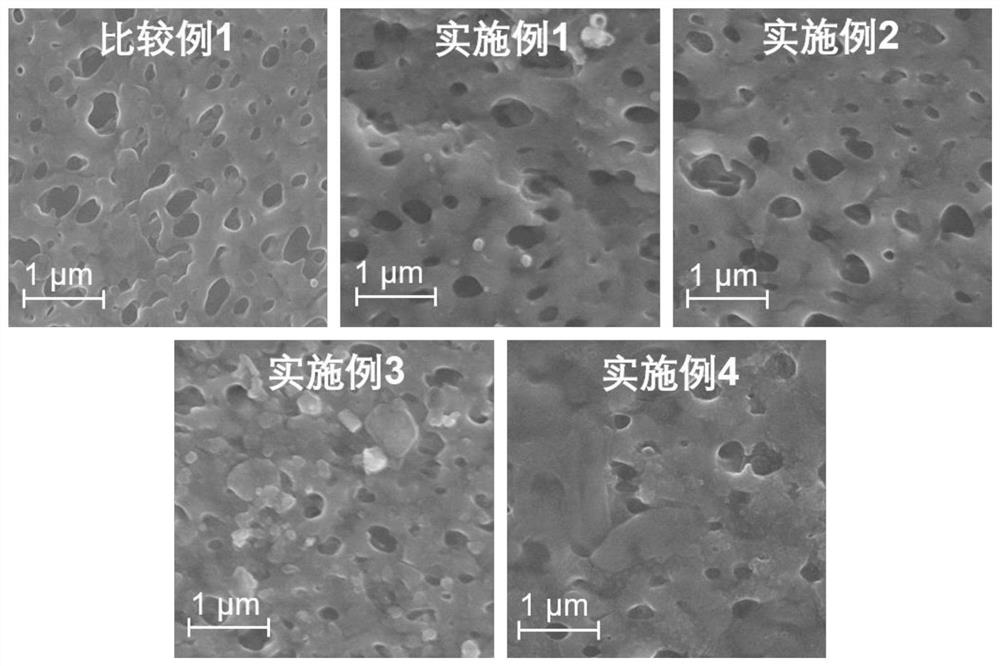

[0028] (1) Prepare 80 mL of 10 mg / L sodium alginate aqueous solution, and then vacuum filter it onto a circular polyethersulfone microfiltration membrane (pore size 0.22 μm) with a diameter of 4 cm to obtain a polysaccharide-contaminated basement membrane, that is, the basement membrane The complex of the membrane and the polysaccharide fouling layer (such as figure 1 As shown, the basement membrane surface has been successfully polluted by polysaccharide);

[0029] (2) dissolving piperazine in water to form a first solution with a mass concentration of 0.05%, then place the complex obtained in step (1) in the first solution and soak for 2 minutes, then take it out, and remove excess liquid on the surface of the complex with a rubber roller drop;

[0030] (3) Dissolving trimesoyl chloride in n-hexane to form a second solution with a mass concen...

Embodiment 2

[0032] Preparation of high-performance polyamide composite separation membrane based on protein fouling base membrane:

[0033] (1) Vacuum filter 80 mL of 10 mg / L bovine serum albumin aqueous solution onto a circular polyethersulfone microfiltration membrane (pore size 0.22 μm) with a diameter of 4 cm to obtain a protein-contaminated basement membrane, that is, basement membrane and protein contamination complex of layers (such as figure 1 As shown, the basement membrane surface has been successfully contaminated with protein);

[0034] (2) dissolving piperazine in water to form a first solution with a mass concentration of 0.05%, then place the complex obtained in step (1) in the first solution and soak for 2 minutes, then take it out, and remove excess liquid on the surface of the complex with a rubber roller drop;

[0035] (3) Dissolving trimesoyl chloride in n-hexane to form a second solution with a mass concentration of 0.04%, then immersing the complex after step (2) i...

Embodiment 3

[0037] Preparation of high-performance polyamide composite separation membrane based on humic acid-contaminated base membrane:

[0038] (1) 80mL of 10mg / L humic acid aqueous solution is vacuum filtered onto a circular polyethersulfone microfiltration membrane (aperture 0.22 μm) with a diameter of 4cm to obtain a humic acid-contaminated basement membrane, that is, basement membrane and The complex of humic acid pollution layer (such as figure 1 As shown, the basement membrane surface has been successfully polluted by humic acid);

[0039] (2) dissolving piperazine in water to form a first solution with a mass concentration of 0.05%, then place the complex obtained in step (1) in the first solution and soak for 2 minutes, then take it out, and remove excess liquid on the surface of the complex with a rubber roller drop;

[0040] (3) Dissolving trimesoyl chloride in n-hexane to form a second solution with a mass concentration of 0.04%, then immersing the complex after step (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com