A high-throughput composite membrane preparation method

A composite membrane and high-flux technology, applied in the field of membrane separation, can solve the problems of limited scale application and structural instability in the chemical synthesis process, and achieve the effect of controllable membrane structure and performance, reduced thickness, and realized flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

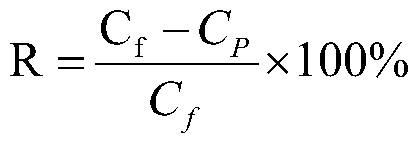

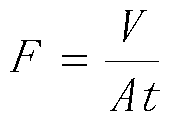

[0045] Let the water phase solution (PIP) flow slowly on the PVC base membrane for 5 minutes, then purge the residual water phase solution on the surface of the membrane for 5 minutes, and then treat the module at -20°C for 2 minutes at low temperature, and install an insulation layer on the module after taking it out. maintain its temperature. Allow the organic phase solution (TMC) to flow slowly on the membrane surface for 2 minutes, then stop the flow, empty the residual solution, let it stand for 15 minutes, and wash it with pure water to be tested. The interception rate measured by this method is 93.98%, and the water flux is 36.75L / (m 2 h).

Embodiment 2

[0047] The low temperature treatment time in Example 1 was changed to 4min, and other conditions were unchanged, to prepare polyamide nanofiltration membrane. The interception rate measured by this method is 96.02%, and the water flux is 48.21L / (m 2 h).

Embodiment 3

[0049] The low temperature treatment time in Example 1 was changed to 6min, and other conditions were unchanged to prepare a polyamide nanofiltration membrane. The interception rate measured by this method is 95.95%, and the water flux is 52.83L / (m 2 h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com