A combined hardness removal device

A combined, hardness technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high residual concentration of calcium and magnesium ions, incomplete reaction, product water rise High-level problems, to achieve good removal effect, ensure the overall effluent water quality, and ensure the effect of water passing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The combined hardness removing device of the present invention will be further described below in conjunction with the accompanying drawings.

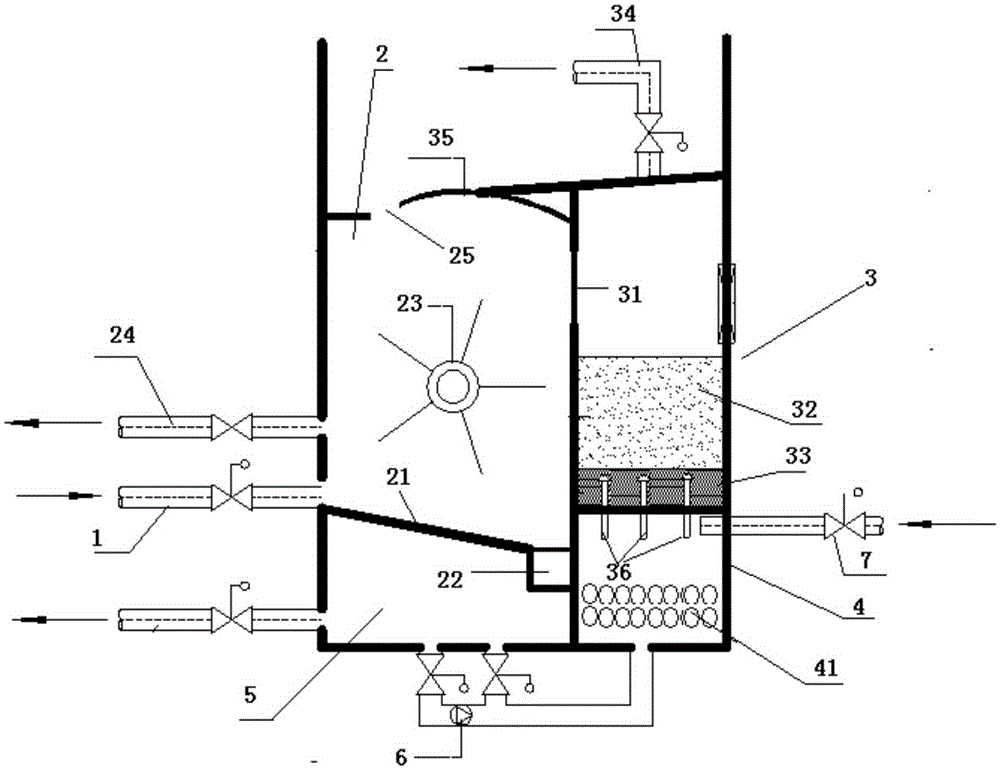

[0024] Combined hardness removal device, see figure 1 , including a water inlet unit 1, a sediment generation reaction unit 2, a filtration separation unit 3, a water quality improvement unit 4 and a clear water tank 5 connected in sequence;

[0025] The water inlet unit 1 is provided with a hardness removing agent and a coagulant dosing port.

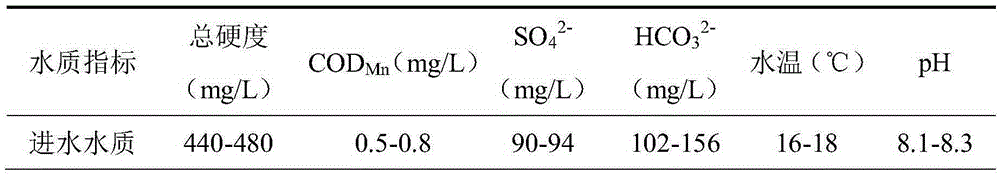

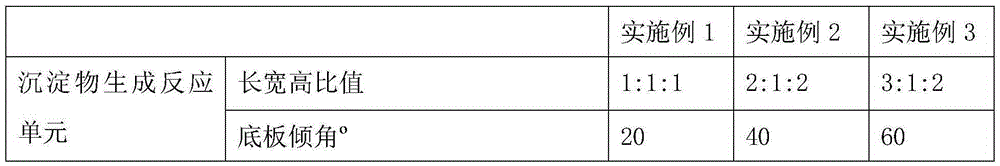

[0026] The sediment generation reaction unit 2 is a cuboid or a cube, and its aspect ratio is between 1:1:1-3:1:2; the sediment generation reaction unit 2 is filled with calcium carbonate and coagulant formed Floc, the concentration is between 1-20g / L. The bottom plate 21 of the sediment generation reaction unit 2 is set obliquely, with an inclination angle of 20-60°; the water inlet unit 1 is connected to the upper edge of the bottom plate 21, and the water inlet direction is set towa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com