Degradable photocurable resin and preparation method thereof

A photocurable resin, degradable technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problem of difficult degradation of photocurable resins, and achieve the effect of fast curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

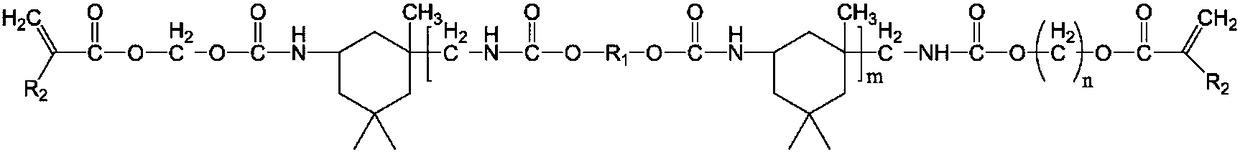

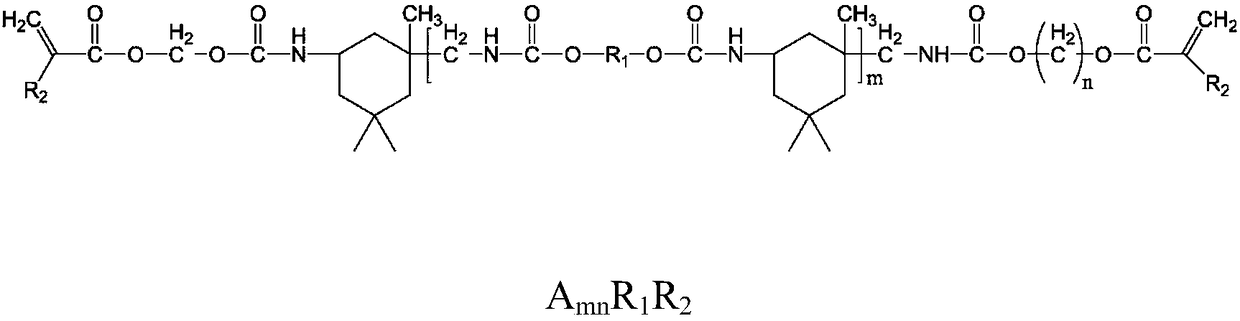

[0027] A 12 B 6 DCH 3 Synthesis

[0028] Add 50.0 g of polylactide diol with an average molecular weight of 500, 44.4 g of isophorone diisocyanate and 0.19 g of dibutyl tin dilaurate into a flask equipped with a mechanical stirrer, and stir at 45°C for 10 hours. Add 26.0g of hydroxyethyl methacrylate and 0.12g of hydroquinone and react at 50℃ for 12 hours to obtain A 12 B 6 DCH 3 .

[0029] The product is characterized by NMR:

[0030] 1 H-NMR(600MHz, CCl 3 D): δ6.07(s), δ5.52(s), δ4.83-5.13 (m), δ4.22-4.29(m), δ3.99-4.09(m), δ3.70-3.81( m), δ3.17-3.25, δ2.86(s), δ2.09(s), δ1.90(s), δ0.80-1.66(m).

Embodiment 2

[0032] A 12 B 13 DCH 3

[0033] Add 100.0g polylactide diol with an average molecular weight of 1000, 44.4g isophorone diisocyanate and 0.43g dibutyltin dilaurate into a flask equipped with a mechanical stirrer, and stir at 80°C for 4 hours. Add 26.0g of hydroxyethyl methacrylate and 0.17g of hydroquinone and react at 60°C for 36 hours to obtain A 12 B 13 DCH 3 .

[0034] The product is characterized by NMR:

[0035] 1 H-NMR(600MHz, CCl 3 D): δ6.08(s), δ5.54(s), δ4.71-5.12 (m), δ4.23-4.28(m), δ3.98-4.10(m), δ3.63-3.81( m), δ3.16-3.20, δ2.85(s), δ1.90(s), δ0.81-1.65(m).

Embodiment 3

[0037] A photo-curable resin with degradability, wherein the mass percentage of each component is:

[0038] A 12 B 6 DCH 3 43.6%, 27.7% of hydroxyethyl methacrylate, 27.7% of ethylene glycol dimethacrylate, 1% of phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide, mix and stir the above materials Evenly. The properties of the obtained photocurable resin with degradability are: double bond conversion rate 62.9%, gel content of cured product 98.5%, bending strength 87.2MPa, bending modulus 2184MPa, degraded weight loss 5.1% after 10 weeks of immersion in simulated body fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com