Injection agent for water injection well and preparation method and application of injection agent

A technology of injection enhancer and water injection well, which can be used in chemical instruments and methods, earth-moving drilling and production, wellbore/well components, etc. It can solve the problem of increasing the permeability difference between layers, damage to low permeability layers, and reducing reservoir permeability. and other problems, so as to reduce the surface and interfacial tension of the reservoir, improve the development effect of water flooding, and reduce the capillary resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a water injection well injection booster, the raw material composition of the water injection well injection booster comprises: 8.0% sulfamic acid, 12.0% methanol, 15.0% tartaric acid, 12.0% ethylenediaminetetramethyl Forked phosphoric acid, 8.0% sodium polyacrylate, 5% cocoyl isethionic acid and the balance water.

[0027] The above-mentioned injection booster for water injection wells is prepared through the following steps:

[0028] At 15°C-25°C, add tartaric acid, ethylenediamine tetramethylene phosphoric acid, sodium polyacrylate, cocoyl isethionic acid and water to sulfamic acid in sequence, stir, add methanol, stir, and obtain a water injection well Use booster.

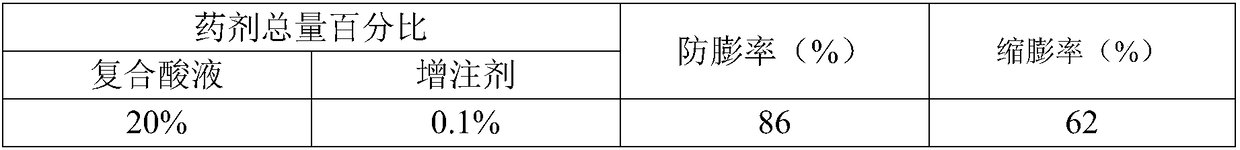

[0029] The anti-expansion rate, shrinkage rate and reduction of oil-water interfacial tension of the above-mentioned injection booster of this embodiment were tested indoors, and the experimental data are as follows.

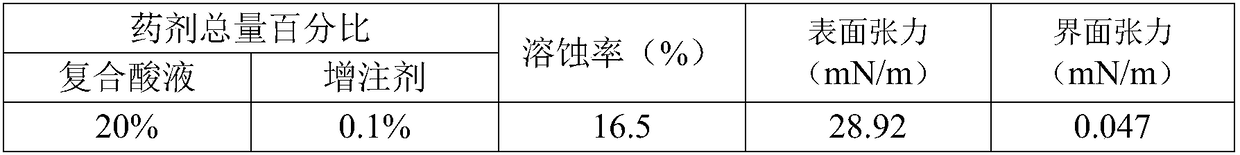

[0030] (1) Table, interfacial tension evaluation

[0031]...

Embodiment 2

[0045] This embodiment provides a water injection well injection booster, the raw material composition of the water injection well injection booster comprises: 10.0% sulfamic acid, 15.0% methanol, 12.0% tartaric acid, 15.0% ethylenediaminetetramethyl Formic phosphoric acid, 6.0% sodium polyacrylate, 7% cocoyl isethionic acid and the balance water.

[0046] The above-mentioned injection booster for water injection wells is prepared through the following steps:

[0047] At 15°C-25°C, add tartaric acid, ethylenediamine tetramethylene phosphoric acid, sodium polyacrylate, cocoyl isethionic acid and water to sulfamic acid in sequence, stir, add methanol, stir, and obtain a water injection well Use booster.

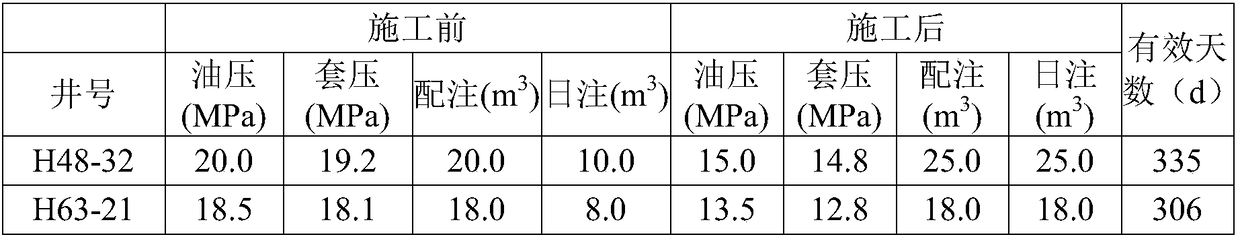

[0048] The anti-expansion rate, shrinkage rate and reduction of oil-water interfacial tension of the above-mentioned injection booster of this embodiment were tested indoors, and the experimental data are as follows.

[0049] (1) Table, interfacial tension evaluation

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com