High-reflectivity material surface defect thermal imaging detection system and method

A technology of high reflectivity and detection system, applied in the field of detection, can solve the problems of time-consuming, light pollution of the inspectors, and slow detection speed, and achieve the effect of avoiding light pollution, fast inspection speed and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

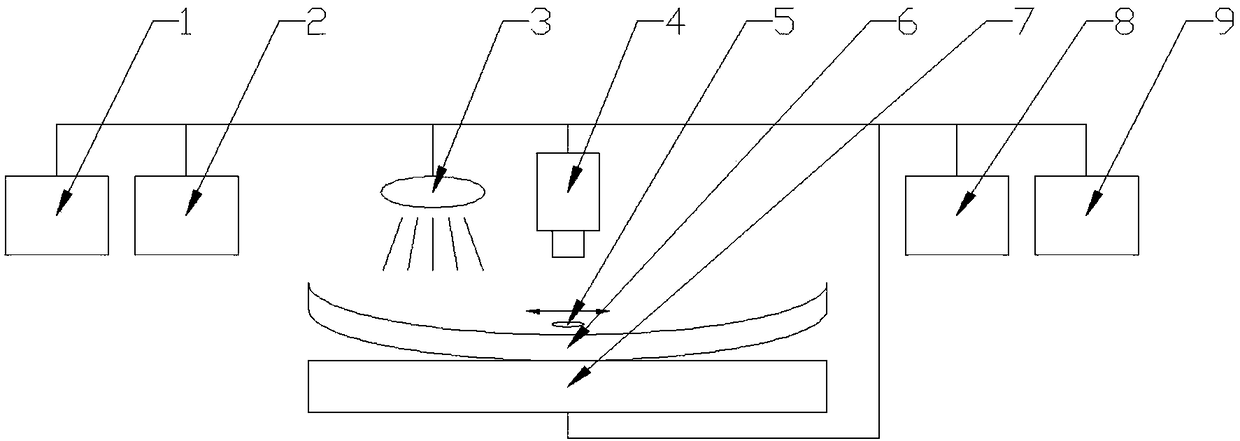

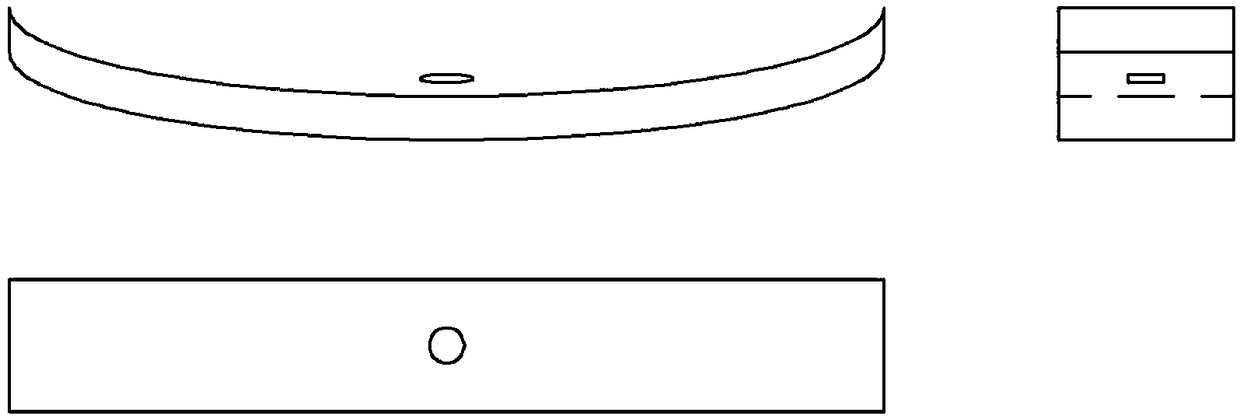

[0026] figure 1 As shown, a passive thermal imaging detection system for surface defects of high-reflectivity materials, the measured object 6 is an object with high surface reflectivity, which can be a high-reflectivity object of any shape and size. The detection system includes a parameter detection module 3, a system control module 1, an infrared measurement imaging module 4, a focus flag 5, a focus flag production module 2, a motion control module 7, a signal processing module 8 and a diagnosis module 9, and the system control module 1 can Use a computer.

[0027] The system control module 1 controls the laser scanning array or 3D scanner in the parameter detection module 3 to work to obtain the morphological parameters of the measured object 6, such as curvature, etc., and controls the triggering, disconnection, and working time of the infrared measurement imaging module 4, and The focus flag making module 2 makes the focus flag 5 and the linkage of other related modules...

Embodiment 2

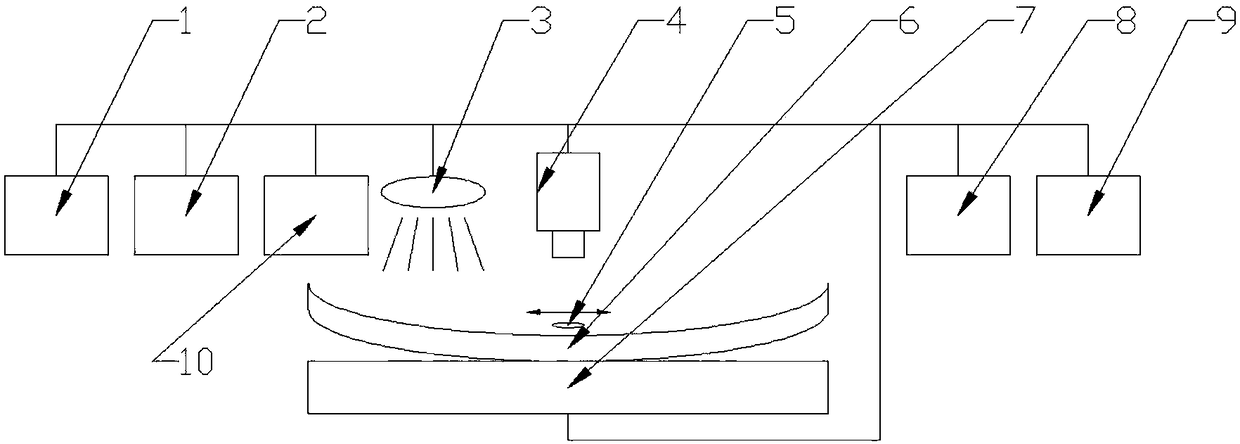

[0047] figure 2 As shown, an active thermal imaging detection system for surface defects of high-reflectivity materials, in order to further improve the detection signal-to-noise ratio, different excitation methods can be adopted to improve the detection effect, so the system can be added to the excitation module 10, the excitation module 10 It can be halogen lamp, flash lamp, laser, electromagnetic induction, electric current or ultrasonic, etc. The principle is: use these excitation modules 10 to give an excitation to the measured object 6, so that the measured object 6 has heat injection, and the defect position causes the surface heat distribution to be abnormal, and the defect parameters are inverted by observing the surface heat distribution.

[0048] A thermal imaging detection method for surface defects of high-reflectivity materials, using the above-mentioned detection system to perform intelligent detection of micro-crack defects on the surface of high-reflectivity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com