Iron core excitation device and method for seeking and recovering breakdown range of pouring coil

A technology of excitation device and excitation coil, applied in coil manufacturing, measurement device, transformer/inductor coil/winding/connection, etc., can solve the problems of broken transformer core, scrap, cumbersome, etc., to prevent material waste and reduce cumbersome process, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

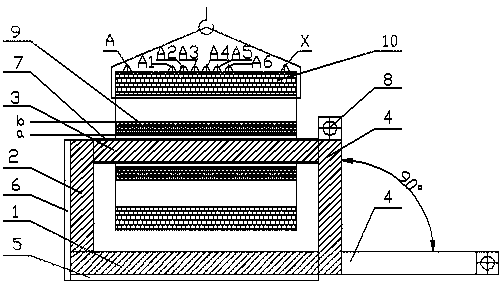

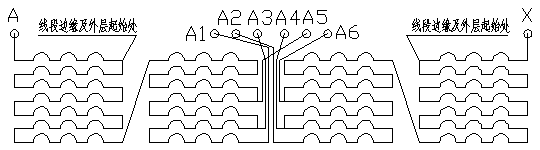

[0038] An iron core excitation device, which replaces the original transformer core, is composed of four square cross-sections, the first iron core column 1, the second iron core column 2, the third iron core column 3, and the movable iron core column 4 to form a closed magnetic circuit. With the base clip 5, the second clip 6, the latitude-free tape 7, the moving clip 8, and the excitation coil 9, an iron core excitation device is formed (see figure 1 ).

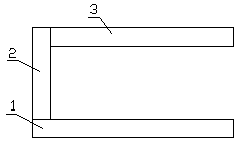

[0039] The overlap between the first core column 1, the second core column 2 and the third core column 3 is a right-angled seam that is repeatedly staggered and stacked into a "匚" shape (see figure 2 ), the first core column 1 is clamped with two base clamps 5 and used as a floor base; the second core column 2 is clamped with two second clamps 6; the third core column 3 is clamped with no weft The belt 7 is fastened and solidified into an integral structure; the movable core column 4 is clamped by a movable clamp 8 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com