High-performance hollow silicon-carbon graphene ternary composite negative electrode material and preparation method thereof

A ternary composite, negative electrode material technology, applied in electrical components, battery electrodes, electrochemical generators, etc., can solve the problems of particle cracking and pulverization, difficult to form solid electrolyte membrane, etc., to achieve less environmental pollution, avoid local temperature overshoot The effect of high and stable electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

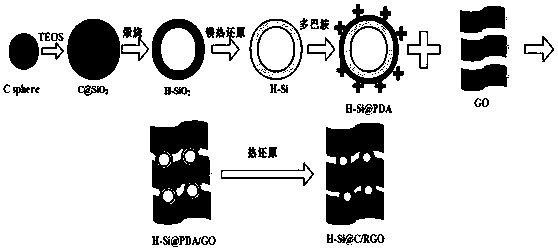

[0033] A method for preparing a high-performance hollow silicon-carbon-graphene ternary composite negative electrode material, comprising the following steps:

[0034]1) Preparation of carbon spheres: Dissolve 3.5g of glucose in 60g of deionized water, then add 1g of methanol and stir evenly, add dropwise 1mol / L sodium hydroxide solution, adjust the pH to 8, stir evenly, put into the reaction kettle, and Take it out after reacting at 180°C for 8 hours, and after natural cooling, take out the liner of the reaction kettle, filter with suction and wash the filter cake with ethanol to obtain a carbon sphere template, and dry the carbon sphere template at 60°C for later use;

[0035] 2) Preparation of C@SiO 2 : Disperse 1g of PVP and 0.2g of carbon spheres in a solution of 30mL of ethanol and 30mL of deionized water, and ultrasonically crush for 2 hours to obtain a suspension of carbon spheres. Add 9 mL of ammonia water dropwise to the suspension of carbon spheres under stirring to...

Embodiment 2

[0039] A method for preparing a high-performance hollow silicon-carbon-graphene ternary composite negative electrode material, comprising the following steps:

[0040] 1) Preparation of carbon spheres: Dissolve 3.5g of glucose in 60g of deionized water, then add 2g of methanol and stir evenly, add dropwise 1mol / L sodium hydroxide solution, adjust the pH to 8.5, stir evenly, put into the reaction kettle, and After reacting at 180°C for 10 h, take it out, and after natural cooling, take out the liner of the reaction kettle, filter with suction and wash the filter cake with ethanol to obtain a carbon sphere template, and dry the carbon sphere template at 60°C for later use;

[0041] 2) Preparation of C@SiO 2 : Disperse 1g of PVP and 0.2g of carbon spheres in a solution of 30mL of ethanol and 30mL of deionized water, and ultrasonically crush for 2 hours to obtain a suspension of carbon spheres. Add ammonia water dropwise to the suspension of carbon spheres under stirring to adjust...

Embodiment 3

[0046] A method for preparing a high-performance hollow silicon-carbon-graphene ternary composite negative electrode material, comprising the following steps:

[0047] 1) Preparation of carbon spheres: Dissolve 3.5g of glucose in 60g of deionized water, then add 3g of methanol and stir evenly, add dropwise 1mol / L sodium hydroxide solution, adjust the pH to 8, stir evenly, put it into the reaction kettle, and After reacting at 200°C for 6 hours, take it out, and after natural cooling, take out the liner of the reactor, filter with suction and wash the filter cake with ethanol to obtain a carbon sphere template, and dry the carbon sphere template at 60°C for later use;

[0048] 2) Preparation of C@SiO 2 : Disperse 0.8g CTAB and 0.4g carbon spheres in a solution of 60mL ethanol and 60mL deionized water, and ultrasonically crush for 2 hours to obtain a suspension of carbon spheres. Add ammonia water dropwise to the suspension of carbon spheres under stirring to adjust the pH value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com